- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

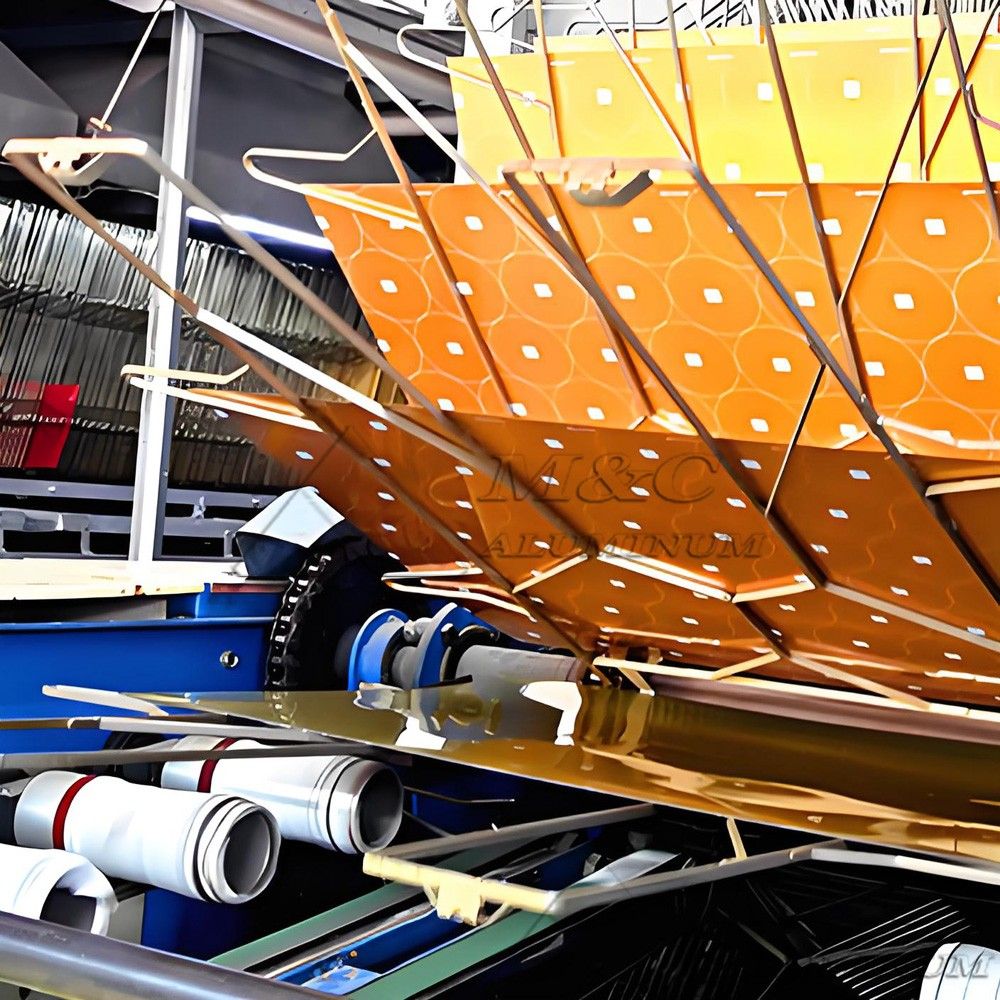

PP Cap Raw Material

3105 aluminum sheet, with its excellent medium strength, superior formability, and high cost-performance ratio, has become one of the preferred materials for producing PP (Pilfer Proof) caps, threaded caps, and carbonated beverage closures.

3105 aluminum belongs to the 3000 series Al-Mn (aluminum-manganese) alloy family. By adding 0.3%-0.8% manganese, its strength and corrosion resistance are significantly enhanced compared to pure aluminum in the 1000 series. One of its main advantages is the low ear rate, making it ideal for rolling, stretching, and deep drawing processes. During deep drawing, the deformation is more uniform and edges remain smooth, improving both the quality and production efficiency of bottle caps.

Typical Tempers: H14, H16, H18 (other tempers available upon request).

Compared to Plastic Bottle Caps

Bottle caps made of 3105 aluminum sheet offer superior sealing performance and a higher quality feel compared to plastic bottle caps.

Aluminum bottle caps effectively prevent oxygen penetration, protecting contents from oxidative damage, making them particularly suitable for products with high preservation requirements, such as beer and wine.

Compared to traditional plastic bottle caps, 3105 aluminum sheet caps are leak-proof. When used with an aluminum foil-coated PE gasket, their oxygen and water permeability are even lower.

In terms of environmental protection, 3105 aluminum sheet is recyclable, meeting the requirements of modern sustainable development. Its production process is relatively energy-efficient, and it can be reused through existing aluminum recycling systems after disposal, reducing the environmental burden.

Key Performance Advantages of 3105 Aluminum for PP Caps

1. High Strength & Impact Resistance: Suitable for high-speed, continuous production lines.

2. Excellent Ductility: Ensures smooth deep-drawing without cracking.

3. Superior Corrosion Resistance: Guarantees long-term sealing performance.

4. Eco-Friendly: 100% recyclable material that supports sustainable packaging.

5. Excellent Workability: Adaptable to stretching, deep drawing, coating, and printing processes.

Technical Specifications

| Alloy | 3105 |

| Temper | H14, H16, H24, H26 |

| Thickness & Tolerance | 0.15-0.25 mm (±0.005 mm) |

| Width & Tolerance | 500-1000 mm (+0.5 mm / -0 mm) |

| Length & Tolerance | 500-1000 mm (+0.5 mm / -0 mm) |

| Coil Length | 500-1000 mm |

| Strip Length | 20-500 mm |

| OEM/ODM | Available |

| Packaging | Standard export seaworthy packing |

| MOQ | 1-3 tons |

Mechanical Properties

| Property | H14 | H16 | H18 |

| Tensile Strength (MPa) | 145-185 | 160-200 | 175-210 |

| Yield Strength (MPa) | 90-130 | 100-140 | 110-150 |

| Elongation (%) | 10-18 | 8-15 | 6-12 |

| Brinell Hardness (HB) | 35-50 | 45-55 | 45-60 |

Physical Properties

| Density | 2.71 g/cm³ |

| Melting Point | 643-650°C |

| Thermal Conductivity | 160-180 W/m·K |

Application Fields of 3105 Aluminum Closure Sheet

Beverage Packaging:

Especially suitable for carbonated beverage caps due to its pressure resistance and secure sealing. Also widely used in non-carbonated drinks and general beverage packaging.Wine and Spirit Closures:

Ideal for crown caps and liquor bottle seals. Its excellent printability allows brand logos and decorative elements to be vividly displayed, enhancing brand image and shelf appeal.Cosmetic and Pharmaceutical Packaging:

The hygienic and chemical-resistant nature of 3105 aluminum ensures product purity. It resists chemical reactions and contamination, maintaining the stability and safety of cosmetics and pharmaceuticals.

How to Choose High-Quality 3105 Aluminum Sheet for PP Caps

1. Material Temper:

For bottle cap production, O (annealed) or H18 tempers are commonly used. The O temper provides higher ductility for deep drawing, while H18 offers greater rigidity for caps requiring high stiffness.

2. Surface Quality:

Directly affects print clarity and visual appeal. Premium 3105 sheets should have a flat surface, free from roll marks, stains, or oil spots-ensuring smooth printing and aesthetic precision.

3. Mechanical Stability:

Pay attention to tensile strength, elongation, and deep-drawing consistency. Ensure the earing rate is maintained below 3% for efficient cap forming.

4. Reliable Supplier:

Choose experienced aluminum manufacturers with advanced production lines and strict quality management systems. This ensures consistent mechanical properties, stable supply, and reliable after-sales service.

Related Articles

- Chromium-Plated and DOS-Treated Aluminum Sheets for Cosmetic Bottle Caps

- 5052 Aluminum strip roll for pull ring can lid

- 8011 H14 aluminum foil for chromated bottle cap materials

- 3105 DD / DC Aluminum Sheet Coil for Closure Applications

- Medicinal aluminum bottle caps

- 3105 H18 aluminum strip for beverage bottle caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan