- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Is 3105 Aluminum Sheet Cost-Effective for Bottle Caps?

2025-10-28

3105 aluminum sheet has higher strength and corrosion resistance while retaining good ductility and processing properties, making it an ideal raw material for food and beverage bottle caps.

8011 Cast-Rolling Aluminum Sheet for Deep-Drawn Wine Bottle Caps

2025-10-24

8011 aluminum closure sheet has good deep drawing performance and low strength, and is widely used in beer, wine, spirits and health product bottle caps.

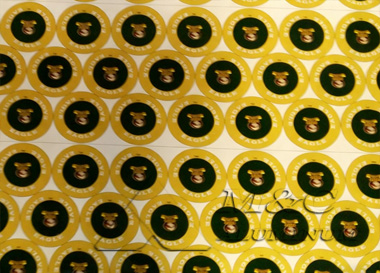

Hot rolled A8011 H16 aluminum strip for high performance anti-theft caps

2025-10-21

Hot-rolled 8011 H16 aluminum strip meets the stringent requirements of deep drawing, spinning, embossing and printing processes, and is widely used in the production of anti-theft bottle caps and beer caps.

Strict Requirements for Aluminum Alloy Bottle Cap Material

2025-10-17

The main products of aluminum plates for bottle caps are 1xxx, 3xxx, and 8xxx series aluminum alloy plates, and the material states usually include H14, H16, H18, H19, etc.

Aluminum Alloy Strips / Sheets for Closures

2025-10-14

The main types of aluminum alloys for capping are 8011, 1060, 3105, 5052, etc., and the main states are H14, H16, H18, H19, etc.

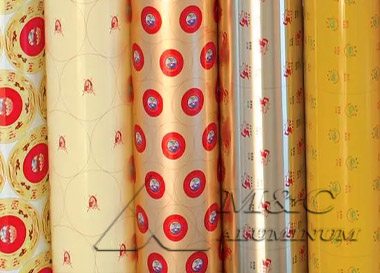

Color Coated Aluminum Sheet for Bottle Caps

2025-10-10

Colored aluminum plate bottle caps are based on 3105, 8011, 5052, 1060 aluminum alloy plates and are used for bottle caps of soft drinks, alcohol, cosmetics, medicines, etc.

1060 3105 5052 8011 Aluminum Closure Sheet for Bottle Caps

2025-09-29

Bottle cap aluminum closure plates are usually made of 1060, 3105, 5052 and 8011 aluminum alloys, which have the advantages of light weight, corrosion resistance and good formability.

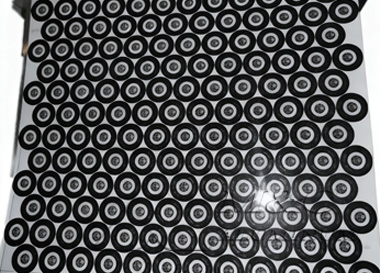

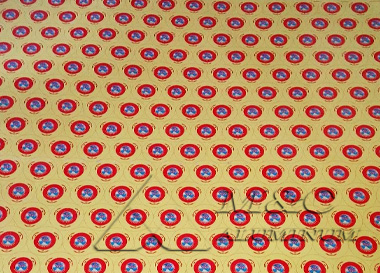

Chromized Aluminum Sheet for Aluminum Bottle Cap

2025-09-26

The 1/3/5/8 series aluminum sealing sheets produced by MC Aluminum are mainly used in the bottle cap market and are widely popular due to their light weight, excellent deep drawing performance and good sealing effect.

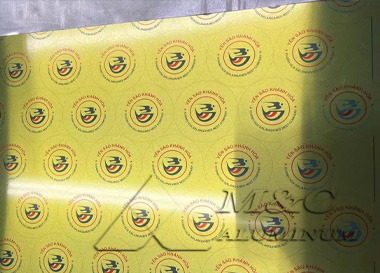

Colored Coated Aluminum Sheet for Beverage Caps

2025-09-23

Color-coated aluminum plates for beverage lids are made of 8011, 3105 and other alloys, with food-grade coatings, good sealing, corrosion resistance and recyclability, and support customized printing. They are widely used in beverage and wine packaging.