- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Medical bottle cap

Alloys:8011, 1060

Temper:H13, H14, H16, H18, H22, etc

Thickness:0.016-0.5mm

Width:100-1600mm

MOQ:1 Ton

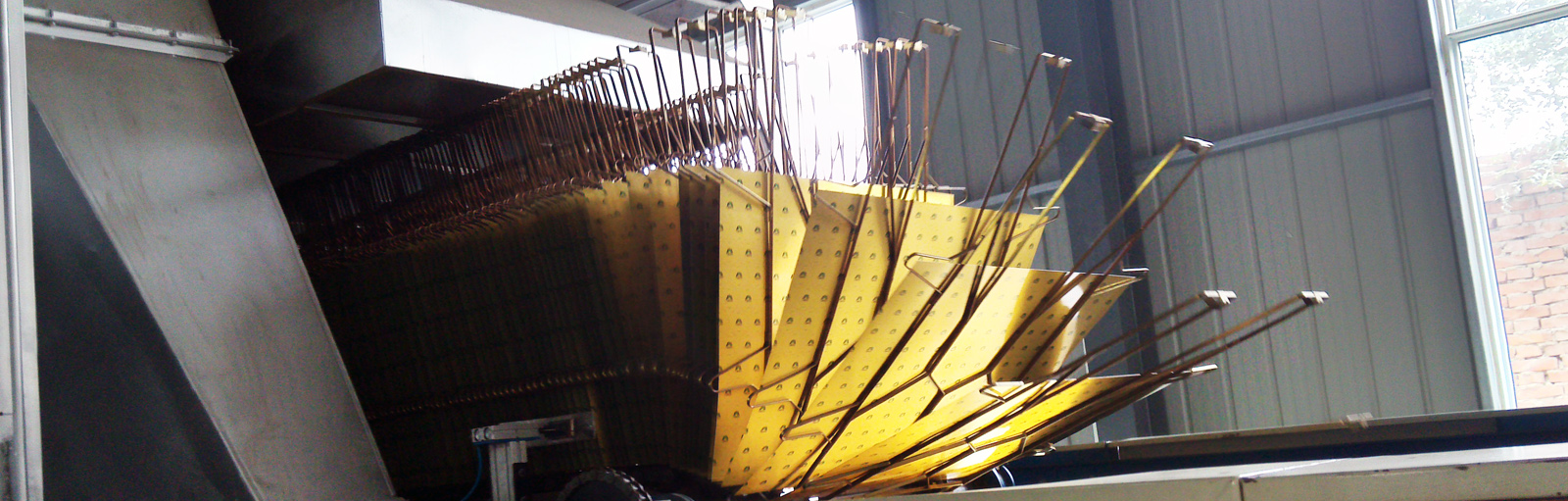

Nowadays, the materials of bottle caps are various, and the commonly used materials of bottle caps are plastic, aluminum alloy and so on. Compared with plastic bottle caps, aluminum caps have more advantages. The production of aluminum caps can be mechanized and large-scale, and the production cost is low, pollution-free, and recyclable. Plastic covers have high processing costs, low production efficiency, poor sealing, and serious environmental pollution, and their demand is decreasing day by day; while the aluminum anti-theft covers developed in recent years have overcome many of the above shortcomings, and their demand is increasing year by year. growing trend. Aluminum caps are widely used in food, medical, cosmetic and other fields.

Medical aluminum caps are used for sealing oral liquids and bottled infusions, etc. Medical aluminum caps are an important part of pharmaceutical packaging, and they are also the first place where consumers come into contact with products. The aluminum cap made of 8011 aluminum foil is thin, easy to open, good airtight performance, and has anti-theft opening and safety functions. It is widely used in pharmaceutical oral liquid, infusion bottles, antibiotic bottles, etc.

Aluminum alloy specifications for medical bottle caps:

| Alloy | 8011, 1060 |

| Temper | H13, H14, H16, H18, H22, etc |

| Thickness(mm) | 0.016-0.5 |

| Width(mm) | 100-1600 |

| Length(mm) | C |

Aluminum alloy advantages for medical bottle caps:

1. Thin and easy to open.

2. The structure is simple, the cost is low, the sealing performance is good, and it is more convenient to use.

3. The torque is stable, which can reduce the opening time.

4. Strong tensile strength and corrosion resistance.

5. The colors are diversified, and the colors and patterns can be customized according to customer preferences.

MC Aluminum is a large-scale manufacturer of aluminum foil raw materials for medical covers. The 8011 aluminum foil and 1060 aluminum foil produced have multiple advantages such as food grade, clean oil removal, less pinholes, and good product shape. Stable product quality, global export, affordable price, you can purchase with confidence!

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan

Get a quote

Get a quote sales@alummc.com

sales@alummc.com

Alloys:

Alloys: