- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

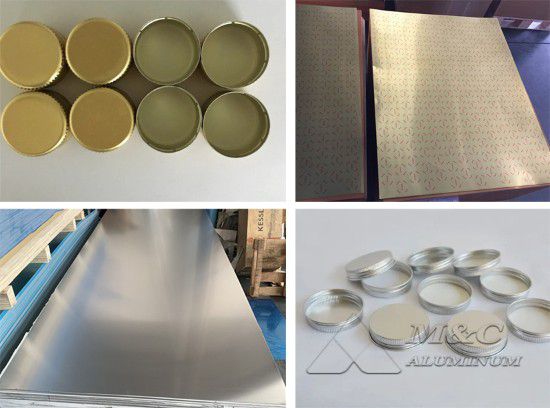

3105 aluminum alloy bottle cap material

3105 aluminum alloy bottle cap material is a new type of bottle cap sealing material, which has the characteristics of exquisite appearance and the function of preventing counterfeit goods and anti-theft. Widely used in sealing packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc.

3105 aluminum closure sheet belongs to the 3 series aluminum-manganese alloy. It has excellent anti-rust properties, good deep drawing effect, high strength, excellent elongation and excellent processing performance. It can meet the needs of automated bottle cap production processes with high intensity. During the processing No creases or cracks, reducing the rate of defective products. The 3105 bottle cap material has a flat shape and smooth surface, without defects such as cracks, bubbles, through-holes, metal and non-metal press-in, light and dark stripes, etc. It is convenient for later printing and the pattern is clearly visible.

Aluminum alloy bottle cap material specifications:

| Alloy | 3105 |

| Temper | H14, H16 |

| Thickness | 0.2-0.45mm |

| Width | 100-1200mm |

| Length | 500-16000mm |

| Usage | bottle caps, closed caps, PP caps, ROPP caps, medical caps, cosmetic caps, can cap materials, etc. |

| Surface type | |

1. Milling 2. Apply DOS oil to lubricate 3.Chrome plating 4. One side is gold/white/red/blue/black, and the other side is coated with protective paint. 5. Double sided varnish/varnish. | |

MC Aluminum specializes in the production of aluminum alloy bottle cap materials, including 3105 aluminum sheet, 8011 aluminum foil, etc. Each process of the aluminum sealing plate used to make bottle caps has strict requirements. We strictly control the material composition, rolling temperature and time, and annealing temperature to ensure Produce the best materials so products have the right strength and formability to meet customer performance needs

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan