- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

3105 Aluminum Sheet for Carbonated Beverage Bottle Caps

3105 aluminum sheet belongs to the Al-Mn series alloy (3xxx series). With manganese as an alloying element, it has better corrosion resistance and mechanical properties than 1xxx pure aluminum. It cannot be strengthened by heat treatment, but mainly relies on cold working hardening and proper annealing to adjust its properties.

3105 aluminum closure sheet features a flat surface, free of roll marks and oil stains, which makes it suitable for high-quality printing (such as large-area fine printing, multi-color printing, and side rolling). It has excellent deep-drawing performance, fully meeting the requirements for producing carbonated beverage bottle caps.

Why Choose 3105 Aluminum Sheet for Carbonated Beverage Closures?

Moderate strength: Able to withstand internal gas pressure, ensuring caps remain intact during filling and transportation, while allowing easy opening by consumers.

Excellent corrosion resistance: The oxide film on 3105 aluminum sheet effectively resists corrosion from sugars, acids, and carbon dioxide, maintaining beverage quality and safety, and extending shelf life.

Superior deep-drawing performance: With excellent plasticity and formability, it allows deep drawing without cracking or wrinkling, improving production efficiency and yield.

Surface treatment friendly: Suitable for printing and coating processes, capable of presenting complex patterns and text with good coating adhesion.

Food-grade safety: Complies with food packaging standards, ensuring no contamination or odor transfer to beverages, guaranteeing consumer safety.

Green & recyclable: Aluminum caps have high recycling value, in line with the packaging industry’s sustainability trends.

Product Information

| Alloy | 3105 |

| Temper | H14, H16, H18 |

| Thickness | 0.20mm - 0.30mm |

| Width | 200mm - 1600mm |

| Length | 100mm - 16000mm |

| Surface | Mill finish, coated, printed |

| Process | DC / CC |

| Packaging | Standard export wooden pallet |

| Sample | Available |

| Applications | Alcohol, carbonated beverages, ROPP caps, screw caps, etc. |

| MOQ | 1-3 tons |

Main Application Fields of 3105 Aluminum Closure Sheet

Besides carbonated beverage bottle caps, 3105 aluminum sheet is also used in:

Alcoholic beverage bottle caps (beer, wine)

Other beverage closures (such as tea drinks)

Food can lids

Cosmetic bottle caps

Pharmaceutical closures

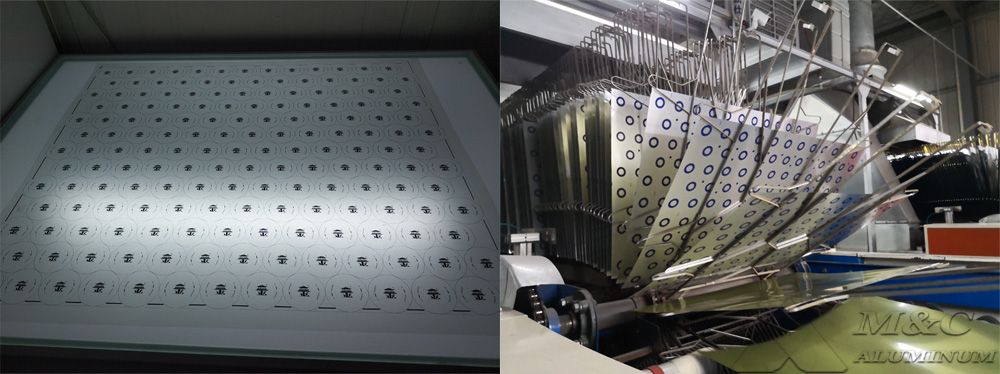

3105 Aluminum Sheet – Processing & Surface Quality Standards

1. Surface Quality

No visible defects: free of roll marks, oil stains, scratches, or oxidation spots, ensuring clear printing.

Cleanliness: surface oil ≤5mg/m² (tested by solvent extraction) to ensure good coating adhesion.

2. Formability

Deep drawing performance: Cup test (ISO 20482) value ≥6mm, ensuring no rupture during cap forming.

Curling performance: Uniform elongation ensures no cracking during edge curling, achieving tight sealing with bottle necks.

3. Batch Stability

Mechanical property deviation ≤3% per batch (to avoid frequent line adjustments).

Thickness variation ≤±0.01mm (to ensure consistent cap weight and filling line accuracy).

3105 vs. 3003 vs. 3004

Comparison: 3105 vs. 3003

3003 is the most widely used 3xxx alloy, with Mn content of 1.0%–1.5%.

Strength: 3105 has slightly higher strength than 3003 because, in addition to manganese, it contains a small amount of magnesium (Mg), further improving strength. For carbonated beverage caps that need to withstand internal gas pressure, 3105 provides more reliable performance.

Formability: Although 3105 is stronger, it retains good formability, essential for deep-drawing. 3003 also has excellent formability and is commonly used in cookware, pipelines, and other products requiring complex shaping.

Applications: 3003 is widely used in areas requiring corrosion resistance and formability but lower strength, such as cookware, storage tanks, and construction materials. 3105, with its slightly higher strength, is better for building applications (roofing, siding) and for closures needing to withstand internal pressure.

Comparison: 3105 vs. 3004

3004 has higher strength than 3003 due to higher magnesium content.

Strength: 3004’s strength approaches that of 5xxx alloys, much higher than 3105.

Applications: 3004’s superior strength makes it ideal for drawn cans (beer cans, beverage cans), which must withstand higher pressure and are usually made by integral drawing processes requiring excellent strength and toughness.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan