- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

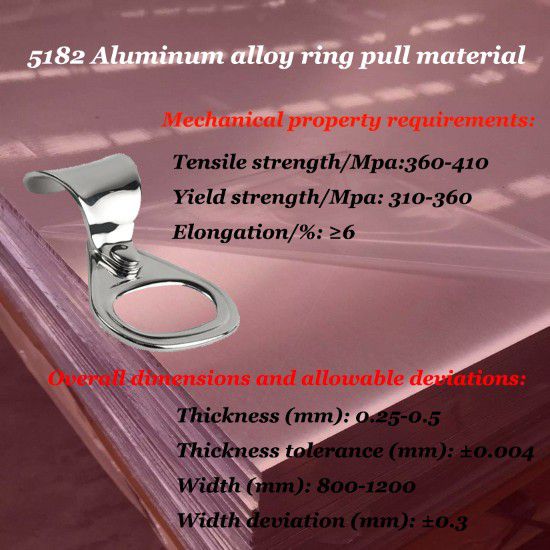

5182 aluminum cover closure sheet

With the improvement of living standards and changes in living and eating habits, people have higher and higher requirements for food packaging. Beverages packaged in aluminum cans are also increasing rapidly. The number of cans used for beer, carbonated drinks, tea drinks, energy drinks, etc. is growing rapidly. , the world consumes hundreds of billions of cans every year, and the number is still increasing. The lid of the aluminum alloy can is made of 5052 aluminum alloy, the pull ring is made of 5182 aluminum closure sheet, and the can body is made of 3104 aluminum alloy and 3004 aluminum alloy. Take 5182 aluminum alloy ring pull material as an example:

5182 aluminum cover closure coil is an Al-Mg-Si alloy with good corrosion resistance, good weldability, good cold workability and medium strength. It has a wide range of applications and is used to manufacture transportation vehicles and ship sheet metal parts. Especially in the construction industry, this alloy is inseparable and is the most promising alloy. With the continuous development of the beverage industry and the replacement of old packaging materials, aluminum Alloy packaging has huge potential, and the market for 5182 aluminum alloy can pull ring materials is good

5182 aluminum closure sheet specifications:

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34H36, H38, H111, H112, H114, H 116, H321 |

| Thickness | 0.25-0.5mm |

| Width | 20-2600mm |

| Length | 500-16000mm |

| Surface | No serious bubbles, missed coatings, scratches, corrosion, oil spots, peeling, stripes, color differences, spots, roller marks, periodicity, etc. that affect the appearance quality of the product are allowed; |

| End face | The end face is neat, rolled tightly without loose layers, staggered layer ≤ 2mm, tower shape ≤ 5mm; |

| Price terms | EXW, FOB, CIF, CFR, CNF, etc. |

| Payment method | L/C, wire transfer, Western Union, etc. |

5182 aluminum cap closure coil---the best material for producing can pull tabs:

1. There is no peeling, bubbles, surface roughness or local mechanical damage on the surface, and there are no defects on the aluminum surface;

2. 5182 aluminum cover closed sheet coil has good corrosion resistance, cold workability and medium strength;

3. The performance of gas welding, argon arc welding, spot welding and seam welding of 5182 aluminum cover closure sheet coils is good;

4. Non-toxic, odorless, green and environmentally friendly, and recyclable.

With the continuous development of the beverage industry and the replacement of old packaging materials, aluminum alloy packaging has huge potential. The products of some large manufacturers have stable quality and superior performance, and have reached the international advanced level. With the development of the market, MC Aluminum continues to provide raw materials to many foreign companies, thus gaining more praise and trust in the international market.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan