- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

8011 Aluminum Closure Sheet Coils for Olive Oil Caps

Why 8011 Aluminum Sheets Are Ideal for Olive Oil Bottle Caps

Aluminum sheets for olive oil bottle caps must meet four key criteria: food contact safety, high barrier performance, corrosion resistance, and aesthetic appeal. Among available materials, 8011 aluminum alloy stands out as the preferred choice due to its excellent overall properties.

8011 aluminum foil is primarily strengthened by silicon (0.5–0.9%) and iron (0.6–1.0%), with aluminum content over 98%. This ensures exceptional plasticity (elongation ≥18%), deep-drawing ear rate below 1.5%, and excellent suitability for complex threaded cap stamping. Common tempers include O, H14, H16, and H18.

Common Tempers and Applications

H14/H16 Temper: These provide moderate hardness and good formability, making them suitable for most standard olive oil caps. They strike a balance between ease of processing and final product performance.

H18 Temper: Offers higher hardness and strength, ideal for designs requiring thinner materials or enhanced cap strength, while still maintaining good deep-drawing capability.

Manufacturers use precision rolling and annealing processes to control thickness (typically 0.15–0.27 mm), surface finish, and mechanical performance to ensure flawless final cap products.

Specifications of 8011 Aluminum Closure Sheets

| Alloy | 8011 |

| Temper | O / H14 / H16 / H18 / H24 |

| Thickness | 0.18 – 0.25 mm |

| Width | 100 – 1300 mm |

| Length | 100 – 6000 mm |

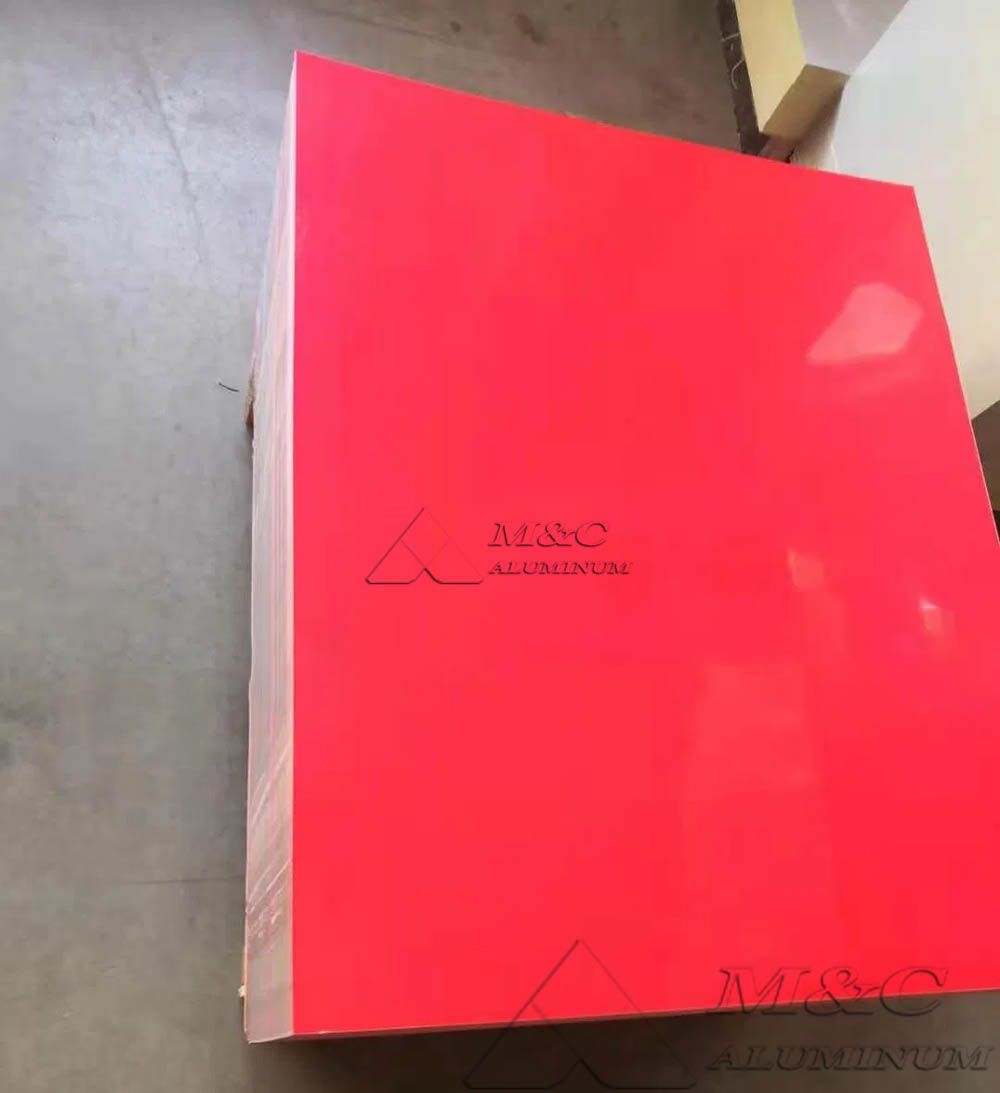

| Surface Treatments | a. Mill finish aluminum strip b. DOS oil-lubricated surface c. Chromate-treated surface d. One side colored (gold/white/red/blue/black, etc.), the other with protective lacquer e. Double-side clear/transparent lacquer |

| Applications | ROPP caps, PP caps, roll-on pilfer-proof caps, aluminum anti-theft caps, aluminum bottle caps, aluminum screw caps, aluminum-plastic tamper-evident caps, etc. |

| OEM/ODM | Accepted |

| Sample | Free |

| MOQ | 1–3 tons |

Mechanical Properties of 8011 H14/H16 Aluminum Closure Sheets

| Tensile Strength (σb) | 125 – 165 MPa |

| Yield Strength (σ0.2) | ≥ 110 MPa |

| Elongation (A50) | 2 – 6% |

| Hardness (HB) | 35 – 60 Brinell |

| Elastic Modulus | 69 – 72 GPa |

| Density | 2.71 g/cm³ |

Key Advantages of 8011 Aluminum for Olive Oil Caps

High Sealability for Product Freshness

Olive oil is highly sensitive to oxidation. 8011 aluminum ensures good elasticity and sealing properties, working with closure liners to form airtight seals that block air and moisture effectively.Excellent Deep-Drawing Performance for Mass Production

Tempers like H14 and H16 offer high ductility, meeting the forming needs of stamping, knurling, and curling—ideal for high-speed automated production lines.Food-Grade Safety, Internationally Certified

8011 aluminum contains no harmful metals and supports food-grade interior coatings (such as BPA-NI), widely used in export packaging and compliant with FDA, EU, and GB food contact standards.Superior Printability and Decorative Appeal

As a key branding surface, 8011 aluminum offers high surface smoothness for fine printing, hot stamping, UV spraying, etc., allowing custom patterns and colors to enhance visual appeal.Sustainable and Eco-Friendly for Green Packaging

Aluminum is 100% recyclable without performance loss, supporting global sustainability goals—especially valued in the environmentally conscious European and American olive oil markets.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan