- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

8011 Aluminum foil bottle cap material

Bottle caps are an important part of food and beverage packaging. They have a certain degree of airtightness to protect the safety and hygiene of the contents. They also have functions such as anti-theft opening. They are widely used in food, beverage industry, alcohol, chemical industry, medicine and other fields. Bottle caps are a key product for bottle container packaging. The choice of materials is of course very important. In recent years, aluminum bottle caps have appeared in daily life. They are simple in shape and fine in production. Advanced printing technology can achieve consistent colors and exquisite patterns. The effect brings an elegant visual experience to consumers.

The alloys selected for aluminum alloy bottle cap materials include 8011 aluminum foil, 3003 alloy, 3004 alloy, 1060 alloy, 3105 aluminum alloy bottle cap material, etc.

8011 aluminum foil has good deep drawing performance, low lug rate, and has a certain strength after baking in the cap making process. In order to ensure that the bottle cap is easy to print after it is formed, the bottle cap material is required to be flat and free of rolling marks, scratches and stains. The alloy material commonly used is 8011-H14, and the material specifications generally have a thickness of 0.20-0.23mm, and the allowable tolerance is ±0.1%, width 449-796mm.

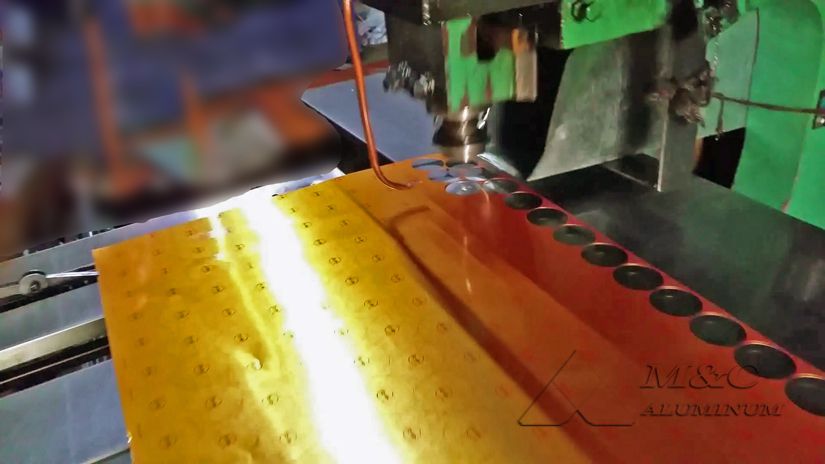

Aluminum bottle cap materials can be produced by hot rolling or continuous casting and rolling, and then cold rolling. Production practice shows that hot-rolled billets are better than cast-rolled billets in terms of the use effect of anti-theft covers.

MC Aluminum is a professional manufacturer of aluminum bottle cap materials. It produces 8011 aluminum foil for bottle cap materials. This alloy has excellent moisture-proof properties, light-shielding properties and high barrier capabilities. The surface is clean, the color is uniform, and there are no spots. At the same time It has high elongation, good sealing and excellent printing effect. It is a commonly used raw material in most bottle cap manufacturers.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan