- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

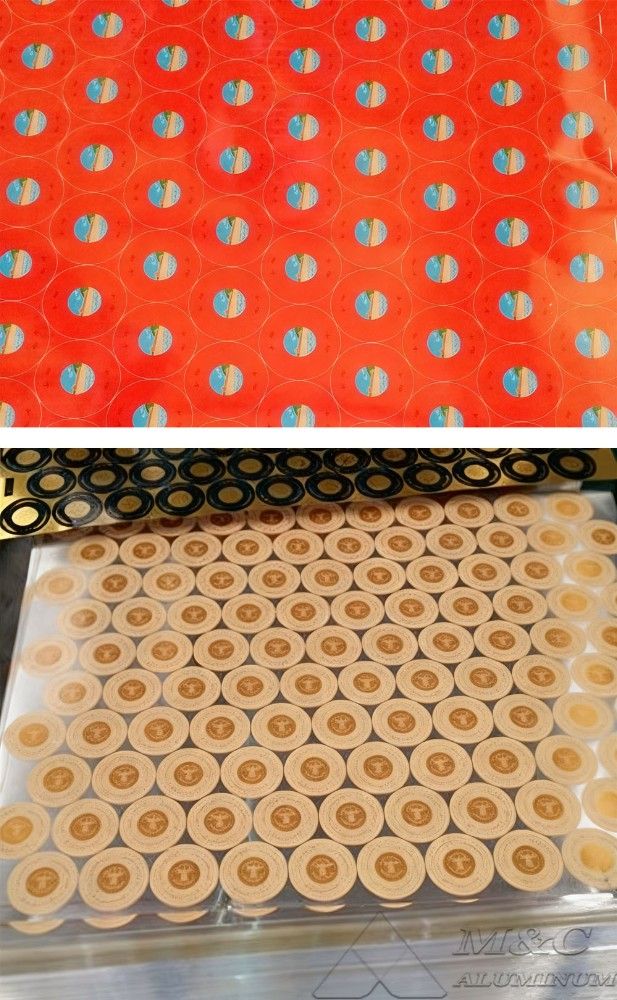

Color Coated Aluminum Sheet for Bottle Caps

Color coated aluminum sheets for bottle caps are made from high-quality aluminum alloy sheets (commonly 3105, 8011, 5052, 1060, etc.). Through a series of processes including surface pretreatment, coating, printing, baking, and stamping, these sheets are transformed into colorful aluminum closures used for sealing various types of bottles.

These caps not only retain the inherent advantages of aluminum - lightweight, rust-resistant, and excellent sealing performance - but also feature diverse designs and branding effects thanks to advanced surface coating and printing technologies. This makes them both functional and decorative.

Aluminum closure sheets are widely used for sealing glass bottles, plastic bottles, and jars for soft drinks, alcoholic beverages, cosmetics, pharmaceuticals, and more. We offer high-quality cap stock to help customers protect the contents of containers while ensuring easy opening, strong sealing, and high efficiency in production.

Specifications of Bottle Cap Aluminum Closure Sheet

| Alloy | 8011, 3105 |

| Temper | O, H14, H24 |

| Thickness | 0.18 – 0.25 mm |

| Width | 50 – 1250 mm |

| Length | 400 – 1000 mm |

| Tensile Strength | 120 – 180 MPa |

| OD | Max 1450 mm |

| ID | 75, 150, 300, 508 mm |

| Diagonal Difference | ≤ 1 mm |

| Coil Density | Max 3.5 kg/mm |

| Earing Rate | < 2 % |

| Surface Quality | Smooth, flat surface without roll marks, black lines, oil spots, dust, scratches, bright streaks, or other defects |

| Rolling Method | 1 – 3 tons |

Why Choose Color Coated Aluminum Sheets for Bottle Cap Manufacturing?

1. Lightweight & Corrosion Resistant

Aluminum has low density, making packaging lighter and easier to transport. The coating provides strong adhesion and excellent resistance to humidity, acids, and alkalis, ensuring no rusting during use.

2. Excellent Sealing Performance

Precision threads and anti-tamper structures ensure a tight seal, ideal for carbonated drinks, wines, pharmaceuticals, and other sensitive liquids.

3. Attractive Appearance & Brand Recognition

Advanced color coating and printing allow for high-resolution patterns and logos, helping to enhance brand image and market competitiveness.

4. Strong Anti-Counterfeiting Features

By integrating laser engraving, holographic printing, and other security techniques, packaging can effectively prevent counterfeiting and ensure product authenticity.

5. Green & Sustainable

Aluminum is 100% recyclable, supporting lightweight and eco-friendly packaging trends in modern industries.

Applications of Color Coated Aluminum Closure Sheet

ROPP caps for wine and spirits (e.g., 30×60 mm, 28×15 mm)

Beverage bottle caps (carbonated drinks, juice, water, etc.)

Food container lids (condiments, edible oils, dairy products)

Pharmaceutical packaging closures

Cosmetics and personal care packaging

Production Process of Color Coated Aluminum Sheet

Aluminum Sheet Pretreatment

Selected aluminum alloy sheets (such as 8011, 3105, or 5052 series) undergo degreasing, cleaning, and chemical conversion (e.g., chromate or zirconium treatment) to enhance coating adhesion.Roll Coating / Primer Application

A primer layer is applied to improve adhesion and provide the first layer of corrosion protection.Color Coating & Curing

Using advanced roll-coating technology, the desired paint is evenly applied and then cured at high temperature to create a durable and uniform color layer.Printing

High-precision offset or screen printing is used to apply logos, designs, or text according to customer requirements, followed by another curing stage.Varnish Coating

A transparent protective varnish is applied to improve wear resistance and gloss, while protecting the printed layer underneath.Stamping & Forming

The printed aluminum sheets are cut into discs or strips, then formed into various types of caps (such as ROPP or pilfer-proof caps) using high-speed presses and molds, including processes like deep drawing, rolling, and threading.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan