- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

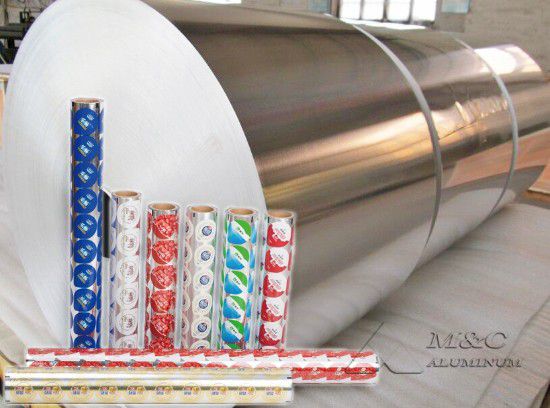

Aluminum foil substrate for beverage bottle caps 8011 H16 H18

Aluminum foil raw material manufacturer for aluminum beverage bottle caps. The company's 8011 aluminum foil, 3105 aluminum sealing plate, 1060 aluminum foil, etc. are the source of aluminum foil raw materials for various aluminum beverage bottle cap factories at home and abroad. It can undertake 1-200 tons of aluminum foil. Raw material orders. (We do not perform subsequent lamination, printing, gluing and other processing processes. We only provide aluminum foil substrates)

Aluminum foil production process for aluminum alloy bottle cap materials:

It is processed using rolling process. First, the aluminum ingot is preheated, and then through continuous casting, rolling and other processes, the aluminum material is flattened into thin sheets to form aluminum foil. Finally, the aluminum foil is made into products of specified size and thickness by cutting and rolling.

Aluminum alloy bottle cap material specifications:

| Alloy | 8011, 3105, 1060, 3003 |

| Temper | H13, H14, H16, H18 |

| Thickness | 0.016-0.5mm |

| Width | 100-1600mm |

| Length | C |

| ID | 75mm, 150mm, 300mm, 500mm, etc. |

| Core material | steel/aluminum |

| MOQ | 1-3 tons |

There are many advantages of using aluminum foil for aluminum drink lids:

1. Barrier properties: Aluminum foil provides an excellent barrier to oxygen, moisture and light, helping to maintain the freshness and quality of your beverages.

2. Heat resistance: Aluminum foil can withstand high temperatures and is suitable for sealing containers that may have gone through a pasteurization or sterilization process.

3. Flexibility: Aluminum foil can be easily molded and shaped to fit different container shapes and sizes, resulting in a tight seal.

4. Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice for packaging materials.

5. Cost-Effectiveness: Aluminum foil is relatively cheap compared to other packaging materials, making it a cost-effective choice for beverage manufacturers.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan