- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Importance of aluminum alloy bottle caps in life

Aluminum bottle cap materials are increasingly used in people's lives, replacing the original tinplate and stainless steel. Aluminum anti-theft bottle caps are made of high-quality special aluminum alloy materials. It is mainly used for the packaging of wine, beverages (with steam and without steam) and medical and health products, and can meet the special requirements of high-temperature cooking and sterilization.

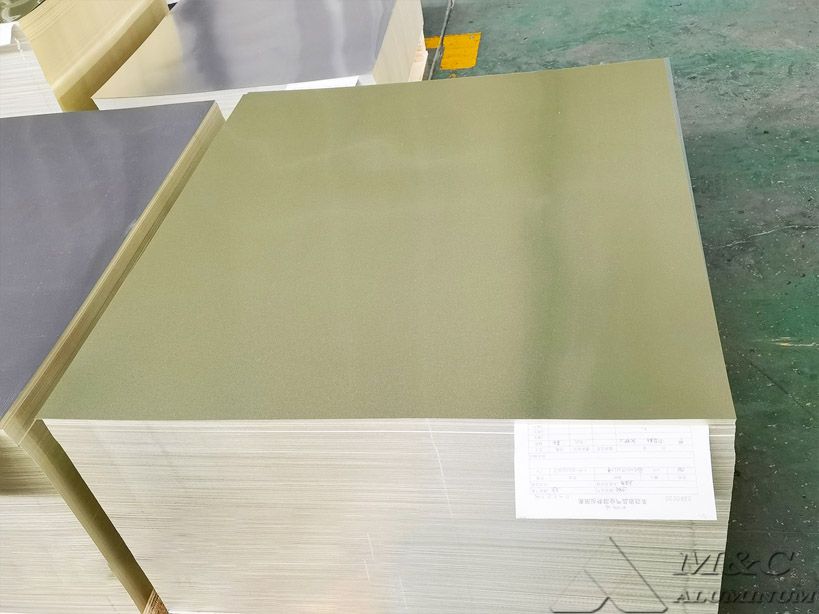

Aluminum bottle caps are mostly processed on production lines with a high degree of automation, so the requirements for material strength, elongation and dimensional deviation are very strict, otherwise they will break or wrinkle during processing. In order to ensure the convenience of printing after the bottle cap is formed, the surface of the aluminum alloy bottle cap material plate is required to be flat, without rolling marks, scratches, and stains. The general alloy state is 8011-H14, 1060, 3105, 5182, 5052, etc., and the material specifications are generally 0.17mm-0.5mm in thickness and 449mm-796mm in width.

Advantages of aluminum bottle caps:

1. Lightweight and durable: Aluminum bottle caps are lighter than other materials, easy to transport and carry, durable and suitable for long-term use.

2. Good sealing performance: It can effectively protect the liquid or food in the bottle, prevent pollution and oxidation, and keep the product fresh.

3. Strong anti-counterfeiting: It can be anti-counterfeited by heat sealing, pull rings, etc., to prevent tampering and forgery, and protect consumer rights.

4. High recyclability: Aluminum bottle caps are recyclable, reduce environmental impact, have a high recycling rate, and help produce recycled aluminum.

5. Good printing performance: It can be printed in a variety of colors and patterns to improve product attractiveness and recognition.

6. Strong antioxidant properties: It effectively prevents oxidation and extends the shelf life of the product.

7. Good appearance processing: A variety of surface treatments enhance aesthetics and market appeal.

8. Environmental protection: Meet environmental protection requirements and reduce resource waste and pollution.

MC Aluminum is a professional manufacturer of aluminum bottle caps, providing 1xxx, 3xxx, 8xxx series aluminum alloy substrates for bottle caps. The company is equipped with extra-long cleaning lines and shears to ensure that the product surface is clean and degreased, and the ear-making rate is low. The company customizes on demand, delivers within 7-35 days, exports worldwide, and is affordable. You can rest assured to purchase!

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan