- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

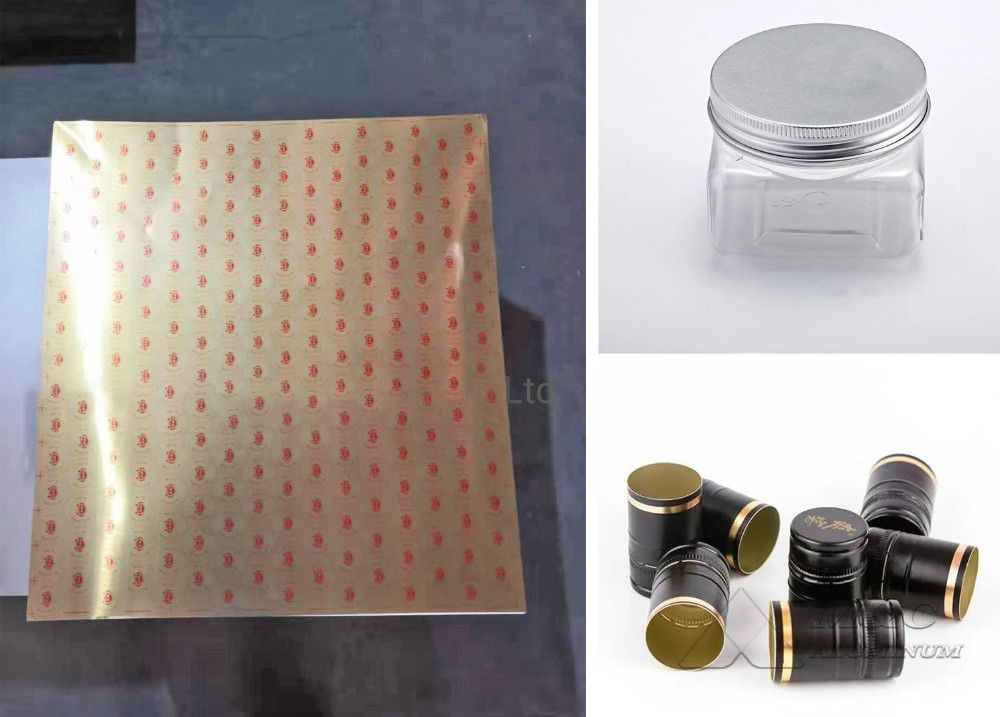

AA8011 aluminum sheet for deep drawing caps

AA8011 aluminum sheet is mainly used to manufacture various caps that require deep drawing processing. It has good deep drawing performance and can meet the processing needs of complex-shaped caps. Such as beverage bottle caps, medical bottle caps, wine bottle caps, etc.

Deep drawing is a metal forming process that stretches metal sheets into complex three-dimensional shapes through a mold. Put the 8011 aluminum sheet into the mold and punch it into the shape of the bottle cap through a press. The surface can be treated according to customer needs, such as oxidation, coating, etc., to improve the corrosion resistance and aesthetics of the bottle cap.

Specifications of deep-drawn aluminum alloy bottle caps:

| Alloy | 8011 |

| Temper | H14, H24, H16, H26 |

| Pattern | rolled, degreased, pre-lubricated, pre-treated, painted |

| Thickness | 0.16-0.23mm |

| Width | 500-1200mm |

| Length | 500-1200mm |

| Coil ID | 75, 150, 300, 500, etc.(mm) |

Application | anti-theft cap, wine bottle cap, small bottle seal, PP cap, ROPP cap, etc. |

Performance advantages of AA8011 aluminum plate for bottle cap:

1. Corrosion resistance

2. Excellent ductility and formability

3. High strength

4. Good mechanical properties

5. Easy to open

6. Exquisite appearance

7. Environmentally friendly and recyclable

8. Safe and hygienic, non-toxic and odorless

MC Aluminum, as a professional manufacturer of aluminum sheet raw materials for bottle caps, provides 8011, 3105 and other aluminum alloy bottle cap materials, which have good formability, corrosion resistance and good flatness, low earing rate and other advantages. It is the preferred material for bottle cap manufacturers. The product quality is good, exported to many countries and regions overseas, and the price is favorable.

Related Articles

- Best Aluminum Alloys for Wine Bottle Caps

- Features of 8011 Aluminum Alloy for Oral Liquid Bottle Cap Material

- Aluminum sheet bottle cap material

- 3105 Aluminum Sheet for Spirits Bottle Caps

- Painted aluminum foil lids for cup yogurt 8011 O

- 1060 H24 stamped aluminum sheet for aluminum anti-theft bottle cap

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan