- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

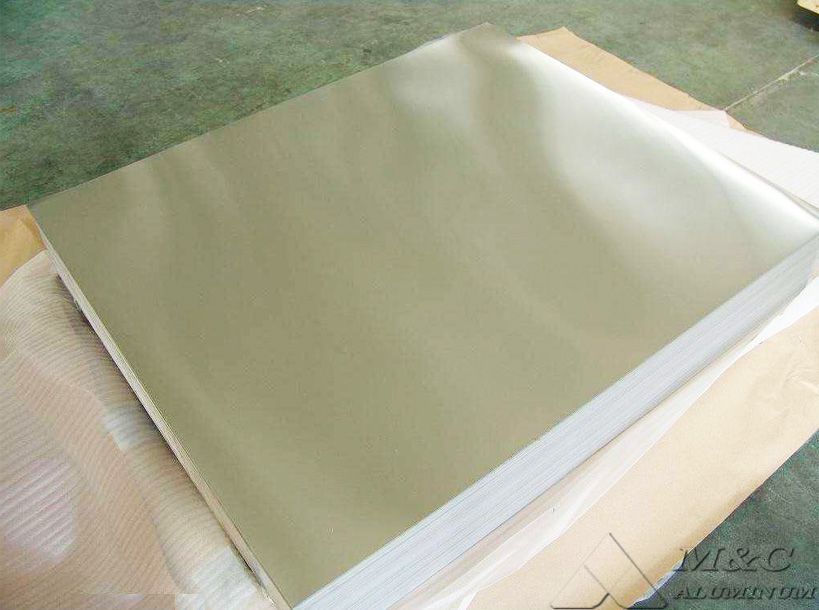

1060 H24 stamped aluminum sheet for aluminum anti-theft bottle cap

Aluminum anti-theft bottle caps are made of high-quality special aluminum alloy materials, with excellent performance, mechanized, large-scale production, and no pollution. Common aluminum bottle cap materials are 1 series, 3 series, and 8 series alloys. Today, we introduce 1060-h24 stamped aluminum sheet for aluminum alloy anti-theft bottle cap

The aluminum caps made of 1060-h24 aluminum sheet are very exquisite and widely used in the packaging of wine, beverages (including gas and non-gas) and medical and health products. They can meet the special needs of high-temperature cooking, sterilization and other high-demand special needs. 1060-h24 aluminum sheet has good forming effect, strong adaptability and good sealing effect. In addition, after anodizing, the 1060-h24 aluminum sheet for aluminum caps has bright color and beautiful appearance.

What is 1060 H24 aluminum sheet?

1060 aluminum sheet belongs to the pure aluminum sheet series, with an aluminum content of more than 99.6%, and has high ductility and flexibility.

H24 state means that the aluminum sheet has undergone a certain hardening treatment and is suitable for subsequent deep processing such as stamping and stretching.

Specifications of 1060 H24 aluminum sheet for aluminum alloy bottle caps:

| Alloy | 1060, 3003, 3105, 5182, 5052, 8011, etc |

| Temper | H24, H14, H16, etc |

| Thickness | 0.2-0.3mm |

| Width | 400-1100mm |

| Strip length | C |

| Sheet length | C |

| MOQ | 1-3 tons |

Mechanical properties:

| Alloy | Tensile strength | Yield strength | Ductility exceeds | Compressive strength |

| 1060 H24 | 65 MPa | 20 MPa | 5% | 60 MPa |

Chemical composition(%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

1060-h24 aluminum sheet is used to make bottle caps:

1. High elongation: good plasticity, easy to process and shape.

2. Tensile strength: has a certain strength, which can meet the material strength requirements of anti-theft bottle caps.

3. Excellent conductivity: suitable for application scenarios requiring conductive properties.

4. High formability: easy to process by stamping, stretching and other processing operations, suitable for manufacturing parts with complex shapes such as bottle caps.

5. Corrosion resistance: Pure aluminum itself has excellent corrosion resistance, especially suitable for packaging materials for food and beverages, which can ensure that bottle caps will not rust or oxidize for a long time in a humid environment.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan