- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

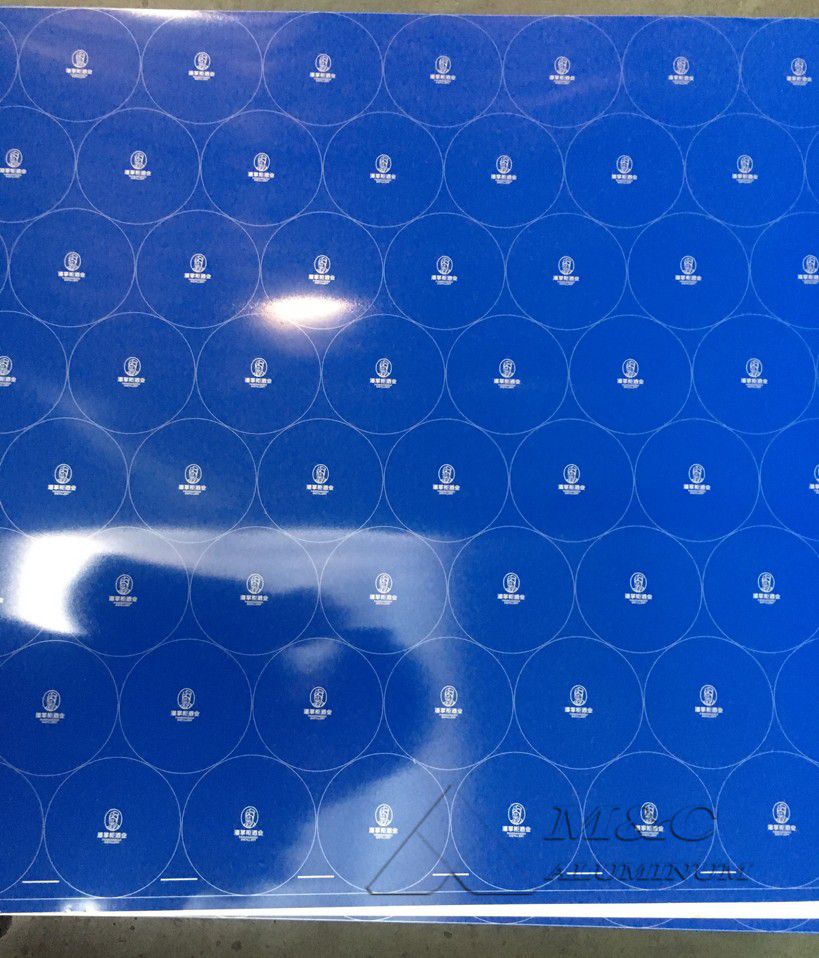

Aluminum alloy plate for beverage bottle caps

Beverage bottle caps are usually made of 1 series aluminum alloy (1060), 3 series aluminum alloy (such as 3003, 3004, 3105) and 5 series aluminum alloy (such as 5052, 5182), which have good corrosion resistance, formability and strength. Widely used in various types of beverage packaging including carbonated beverages, juices, mineral water, beer, etc.

Aluminum alloy bottle cap material specifications:

| Alloy series | 1xxx, 3xxx, 5xxx, 8xxx |

| Alloy | 1060, 3105, 3003, 3004, 5182, 5052, 8011, etc |

| Temper | H14, H16, H24, H26, etc |

| Thickness | 0.20-0.23mm |

| Width | 449-796mm |

| Length | 100-16000mm |

| ID | 75, 150, 300, 508mm |

| OD | 1450mm maximum |

Performance advantages of aluminum alloy bottle caps:

1. Good sealing to prevent liquid leakage

2. Beautiful and elegant, can be decorated to enhance brand image

3. Aluminum bottle caps are easy to open, easy to pull ring or screw cap design

4. Environmentally friendly and recyclable, saving resources, in line with environmental protection concepts

Quality requirements for aluminum closure sheets for bottle caps:

1. Material strength and elongation are crucial for the processing of aluminum bottle caps to ensure that no cracks or creases occur during the production process.

2. In order to ensure the forming accuracy and functionality of the bottle caps, strict requirements are placed on dimensional deviations to avoid sealing or opening problems.

3. Surface flatness is crucial for printing and appearance quality, and rolling marks, scratches and stains need to be avoided.

4. Ensure that the surface of the bottle cap material is clean and free of oil spots to ensure hygiene and safety and avoid beverage contamination.

MC Aluminum needs to strictly control various parameters and process requirements during the processing to ensure that the quality and performance of the bottle cap meet the requirements. At the same time, it is also necessary to conduct strict inspection and testing on the finished product to ensure that it meets the relevant standards and regulations.

Related Articles

- Application of 3105 Aluminum Coil in Bottle Cap Manufacturing

- 8011 H16 anti-theft cover aluminum alloy strip

- 3105 Aluminum Sheet for Carbonated Beverage Bottle Caps

- Aluminum closure sheet for beverage container sealing

- 3105 Red Wine Aluminum Bottle Cap VS Traditional Oak Cork

- Beer bottle cap material aluminum sheet

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan