- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

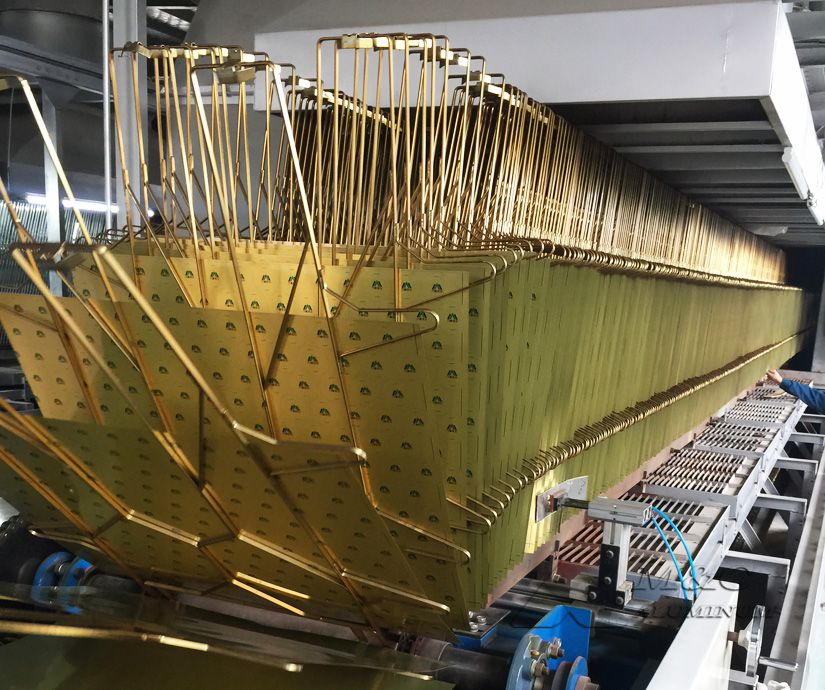

Medical aluminum plastic cover raw materials

Aluminum plastic cap is a kind of medical bottle cap. It is made of aluminum alloy profile and plastic material and processed through special processing technology. It is mainly used for injection bottles and infusion set bottles. Aluminum lids have the ability to keep the contents of the product airtight, and also have anti-theft and security functions. Therefore, they are widely used in bottled products. Therefore, aluminum-plastic lids are used in the upstream industries of the food, beverage, wine, chemical, and pharmaceutical industries. , is a key product for bottle container packaging.

Aluminum-plastic covers are usually made of 8011, 3105 and other aluminum alloys, with conditions of H14, H16, H18, H19, thickness range: 0.016-0.6mm, width: 100-1600mm.

Advantages of medical aluminum plastic covers:

1. Simple structure, light weight and low cost.

2. Good sealing and high strength ensure that the properties of the medicine remain stable and will not change due to transportation, storage, etc.

3. Green, environmentally friendly and recyclable.

4. Rich colors, can be customized according to customer needs, including color and pattern.

5. It usually adopts an easy-open design to facilitate consumers to open the packaging, and is also conducive to the preservation and consumption of the product.

6. Corrosion resistance, able to resist the erosion of chemical substances and ensure product safety.

MC Aluminum is a professional manufacturer of aluminum alloy bottle cap materials, specializing in the production of 8011 aluminum foil, 3105 aluminum closure sheets, etc. for bottle caps. The product plate shape is smooth, clean with oil removal, no marks, no black wire, no burrs, etc. The ear-making rate is less than 2%, reducing the bottle cap defect rate.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan