- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

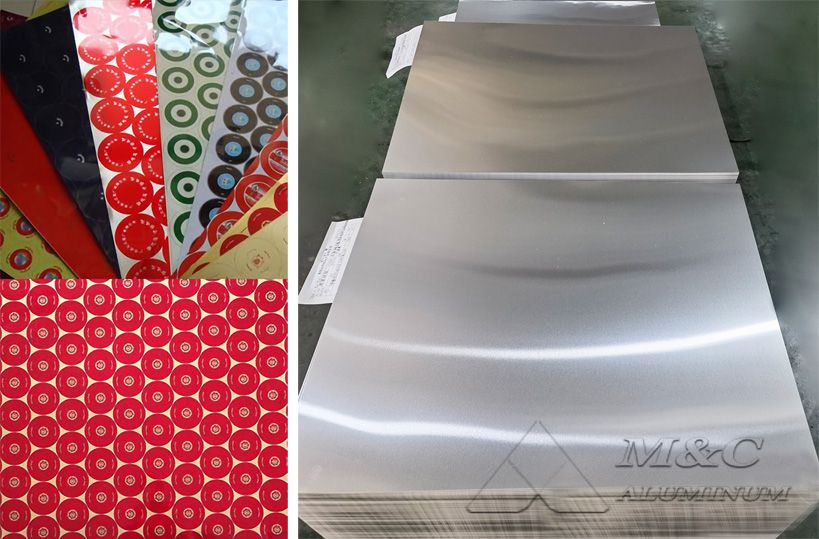

Aluminum PP cap sheet manufacturer

Aluminum PP cap sheets are mainly composed of aluminum and polypropylene (PP) materials. This composite material combines the strength and corrosion resistance of aluminum with the lightness, chemical resistance and easy processing of PP materials, forming a unique performance advantage. MC Aluminum is a manufacturer specializing in the production of aluminum sheets for bottle caps, providing 8011 aluminum alloy and 3105 aluminum closure sheets for the production of PP caps. The common states are H14, H16, etc. The thickness range is 0.16mm-0.23mm, which can be customized according to customer needs.

Aluminum PP cap sheet specifications

| Alloy | 8011, 3105 |

| Temper | H14, H24, H16, H26 |

| Thickness | 0.16mm-0.23mm |

| Width | 50mm-1600mm |

| Length | 500mm-1500mm |

| ID | 76mm, 152mm, 300mm, 350mm, 508mm |

| Surface | rolled, degreased, pre-lubricated, pre-treated, painted |

| Bus coil | CC (continuous casting), DC (direct casting) |

Performance advantages of aluminum closure sheet for PP cap:

1. Higher strength and hardness

2. Corrosion resistance

3. Lightweight, easy to install and transport

4. Easy to process, can customize caps of different shapes and sizes

5. Acid and alkali resistant, long service life

6. Environmentally friendly and recyclable

High quality requirements for aluminum sheets for PP caps:

1. The surface of the aluminum sheet should be smooth, without cracks, corrosion, scratches, oil spots, peeling, stripes, color difference, spots, roller marks and other defects. These defects will affect the appearance quality and sealing performance of the bottle cap.

2. The edges of the aluminum sheet should be cut (cut) neatly, without obvious burrs and sharp edges, to prevent scratches on other parts or personnel during processing and use.

3. For continuously produced aluminum sheets, no joints are allowed.

Related Articles

- Aluminum sheet for twist-off anti-theft cover material 8011A H14 H16

- 25mm Anti-theft aluminum bottle cap material supply

- 8011 3105 Aluminum closure sheet for Wine Screw Cap

- Aluminum PP cap sheet manufacturer

- 8011 H16 anti-theft cover aluminum alloy strip

- Aluminum foil substrate for beverage bottle caps 8011 H16 H18

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan