- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Best Aluminum Alloys for ROPP Bottle Caps

In the production of ROPP (Roll-On Pilfer-Proof) bottle caps, the selection of aluminum alloy must take into account deep-drawing performance, corrosion resistance, cost-efficiency, and food safety compliance.

Currently, the most commonly used aluminum alloys for ROPP caps in the market include the following:

1. Primary Choice: 8011 Aluminum Alloy

8011 aluminum alloy offers excellent formability, high earing resistance, and flatness, making it particularly suitable for deep-drawing processes. It is widely used for wine bottle caps and other beverage closures.

(1) Key Advantages

a. Superior Deep-Drawing Properties

8011 deep-drawing aluminum sheet features excellent ductility and plasticity, meeting the demands of ROPP caps for deep drawing and curl-forming. It ensures smooth processing on high-speed production lines and reduces earing, improving material utilization.

b. High Cost Efficiency

As the most widely used cap alloy, it has low raw material cost and a well-established supply chain.

c. Surface Compatibility

Easily compatible with chromate treatment, lacquering, or printing, making it suitable for custom branding (e.g., silk screen printing, embossing).

d. Moderate Strength

Provides adequate mechanical strength to maintain cap integrity and sealing performance.

(2) Typical Applications

Used in wine, pharmaceutical, and standard beverage bottle caps, such as 30×60mm and 28×15mm sizes.

(3) Mechanical Properties

| Temper | H14 | H16 | H18 |

| Tensile Strength (MPa) | 125–165 | 130–165 | ≥165 |

| Elongation (%) | 2 | 1 | 1 |

| Earing Rate (%) | ≤3 | ≤3 | ≤3 |

2. High-Performance Alternative: 3105 Aluminum Alloy

3105 aluminum closure sheet has medium strength and is commonly used for pressurized container lids.

(1) Key Advantages

a. Higher Strength

Compared to 8011, 3105 offers greater mechanical strength, making it more suitable for withstanding internal pressure.

b. Excellent Corrosion Resistance

Retains aluminum’s inherent corrosion resistance.

c. Good Formability and Weldability

Despite higher strength, it still offers good processability.

d. Stress-Crack Resistance

Especially critical for applications requiring internal pressure tolerance.

(2) Application Scenarios

Pressurized containers (e.g., carbonated drinks, sparkling liquids) that require higher tensile strength (175–225 MPa in H16 temper).

Corrosive environments: Magnesium content (0.2–0.8%) enhances oxide film stability and extends sealing life.

(3) Limitations

Slightly higher cost than 8011 and somewhat reduced deep-drawing extensibility (elongation 1–2%).

(4) Mechanical Properties

| Temper | H14 | H16 | H18 |

| Tensile Strength (MPa) | 150–200 | 175–225 | ≥195 |

| Elongation (%) | 2 | 1 | 1 |

3. Alloys for Special Requirements: 5052 and 3003 Aluminum

5052 Alloy

Extreme Corrosion Resistance: Contains 2.2–2.8% magnesium, making it suitable for marine environments or high-salt contents (e.g., seafood seasoning).

High Strength: Tensile strength of 280–320 MPa (H18), but limited formability (elongation 2–3%).

3003 Alloy

Balanced Performance: Higher strength than 8011 (tensile strength 145–185 MPa), ideal for general-purpose caps requiring moderate reinforcement.

Purchasing Recommendations

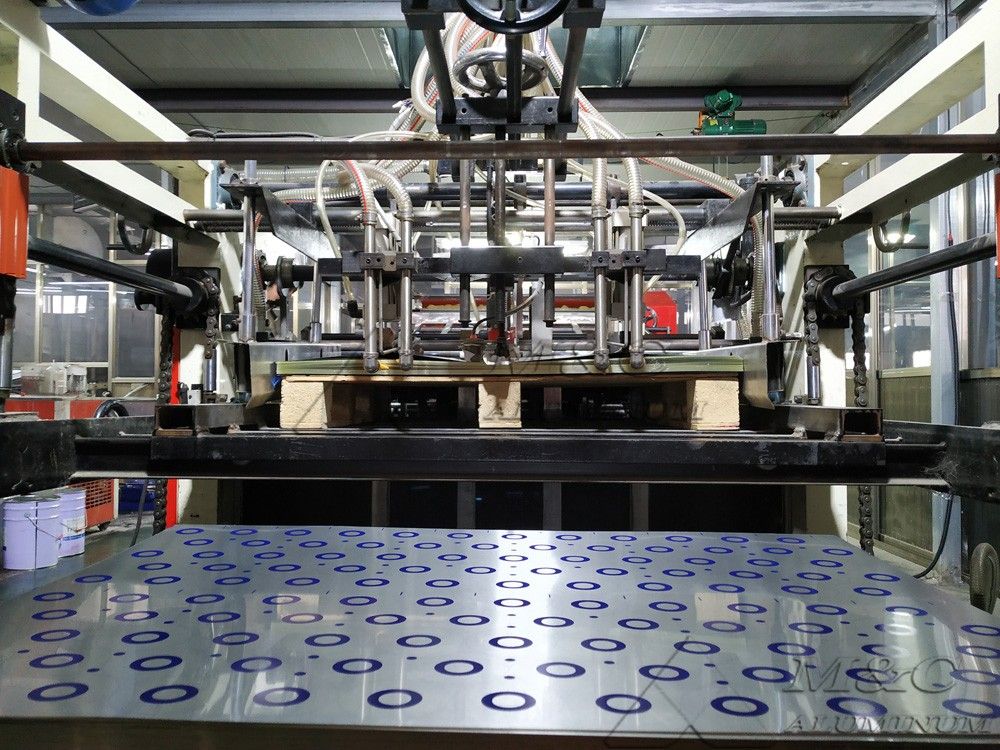

ROPP caps typically require internal coating (e.g., epoxy varnish) to ensure sealing performance and compatibility with contents, along with external printing and decoration. The selected aluminum alloy must offer strong adhesion properties for coatings and be suitable for printing.

Prefer suppliers offering chromate pretreatment and DOS lubrication (e.g., MC Aluminum) to ensure high stamping yield. For bulk orders, request earing rate ≤3% in the quality inspection report.

Related Articles

- 3105 8011 screw aluminum cap

- Printed 8011 3105 aluminum sheet for PP bottle caps

- Aluminum printed plate for Ropp cover 8011 3105

- Features of 8011 Aluminum Alloy for Oral Liquid Bottle Cap Material

- Hot rolled A8011 H16 aluminum strip for high performance anti-theft caps

- 1060 3105 5052 8011 Aluminum Closure Sheet for Bottle Caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan