- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

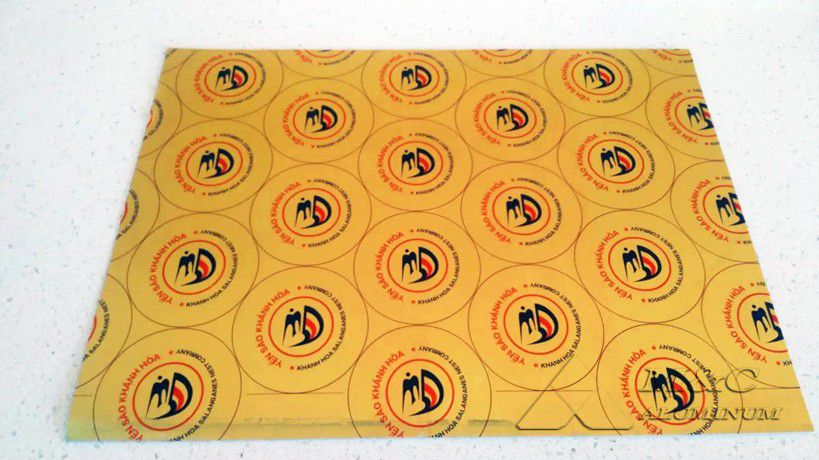

Printed 8011 3105 aluminum sheet for PP bottle caps

PP bottle caps refer to bottle caps made of polypropylene material, using aluminum sheet as the inner lining or outer layer of the bottle cap to improve the performance and function of the bottle cap. PP bottle caps have the advantages of corrosion resistance, light weight, easy opening, and environmental protection, making them ideal for beverage, food, medicine and other consumer product packaging.

Aluminum sheets for PP bottle caps are generally made of 8011 or 3105 alloys. The production of aluminum alloy bottle cap materials can be produced by hot rolling or continuous casting and rolling, and cold rolling. It is widely used in the food and beverage industry for the production of bottle caps, can caps, etc.

Specifications of aluminum sheets for PP bottle caps:

| Alloy | 8011-H14, 3105-H16, etc. |

| Thickness | 0.20-0.23mm |

| Width | 449-2250mm |

| Length | 100-16000mm |

| Surface | The surface of the bottle cap material is required to be flat, without rolling marks, scratches and stains. |

| Coating | Printing on one side and protective paint on the other side |

| Packaging | wooden pallets suitable for sea transportation. |

Advantages of 8011 3105 aluminum sheets for PP bottle caps:

1. Strong sealing

2. Corrosion resistance

3. High strength, not easy to deform or break during transportation, long service life

4. Anti-counterfeiting mark

5. Exquisite appearance, patterns or texts can be printed on the surface

6. Easy to open.

7. Good formability

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan