- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Bottle mouth sealing aluminum sheet

Bottle mouth sealing aluminum sheet is a material used to seal the bottle mouth, usually used in industries such as medicine, food, cosmetics and chemicals to ensure product safety and extend shelf life. Bottle cap material aluminum sheet can be divided into 1100 bottle cap material, 8011 bottle cap material, 8011a bottle cap aluminum sheet, 3003 bottle cap aluminum sheet, 3105 bottle cap material, 5052 bottle cap material according to the alloy grade. Bottle cap materials are all hard, with a hardness between h14-h24, a tensile strength between 110-320, and an elongation generally not less than 4%.

Advantages of aluminum alloy bottle cap material:

1. Moisture-proof and anti-oxidation: The aluminum sheet has good material quality and can effectively block air and moisture to prevent product deterioration.

2. Corrosion resistance: Aluminum sheet has strong corrosion resistance to a variety of chemical substances and is suitable for the sealing needs of various products.

3. Good sealing performance: The bottle mouth is sealed through heat sealing, gluing and other processes to ensure that the product is not contaminated before use.

4. Easy to open: Most sealed aluminum sheets are designed to be easy to tear, which is convenient for users to open.

5. Printing and marking: The brand logo and batch number can be printed on the surface of the aluminum sheet for easy identification and anti-counterfeiting.

6. Beautiful and elegant: The surface of the aluminum material is smooth and bright, which can enhance the overall aesthetics of the product.

7. High temperature resistance: The bottle mouth sealing aluminum sheet can withstand a certain high temperature and is suitable for various heat treatment processes.

7. Environmental protection: The aluminum sheet is recyclable and conforms to the concept of green environmental protection

Specifications of aluminum sheets for bottle caps:

| Alloy | Temper | Thickness | Tensile strength not less than | Elongation is not less than | Earing rate is not greater than |

| 1100 Aluminum Sheet for Bottle Cap | h14 | 0.2--3mm | 110-145 | 2 | 3 |

| H24 | 3 | ||||

| h16 | 130-165 | 1 | |||

| h26 | 2 | ||||

| h18 | 150 | 1 | |||

| 8011.8011a Aluminum sheet for bottle cap | h14 | 0.2--3mm | 125-155 | 2 | |

| h24 | 3 | ||||

| h16 | 145-180 | 1 | |||

| h26 | 2 | ||||

| h18 | 165 | 1 | |||

| 3003 Aluminum Sheet for Bottle Cap | h14 | 0.2--3mm | 145-180 | 2 | 4 |

| h24 | 4 | ||||

| h16 | 170-210 | 1 | |||

| h26 | 2 | ||||

| h18 | 190 | 1 | |||

| 3105 Aluminum Sheet for Bottle Cap | h14 | 0.2--3mm | 150-200 | 2 | |

| h24 | 4 | ||||

| h16 | 175-220 | 1 | |||

| h26 | 3 | ||||

| h18 | 195 | 1 | |||

| 5052 Aluminum Sheet for Bottle Cap | h18 | 0.2--3mm | 280-320 | 3 | |

| h19 | 285 | 2 |

Surface quality of aluminum sheets for bottle caps:

The surface of the aluminum foil is flat, without bright spots, roller marks, grinding wheel marks and black lines.

The surface of the aluminum foil is clean, without corrosion marks, oil marks, wrinkles, slits, scratches, light and dark lines, rubber roller marks, vibration marks, diagonal lines, etc.

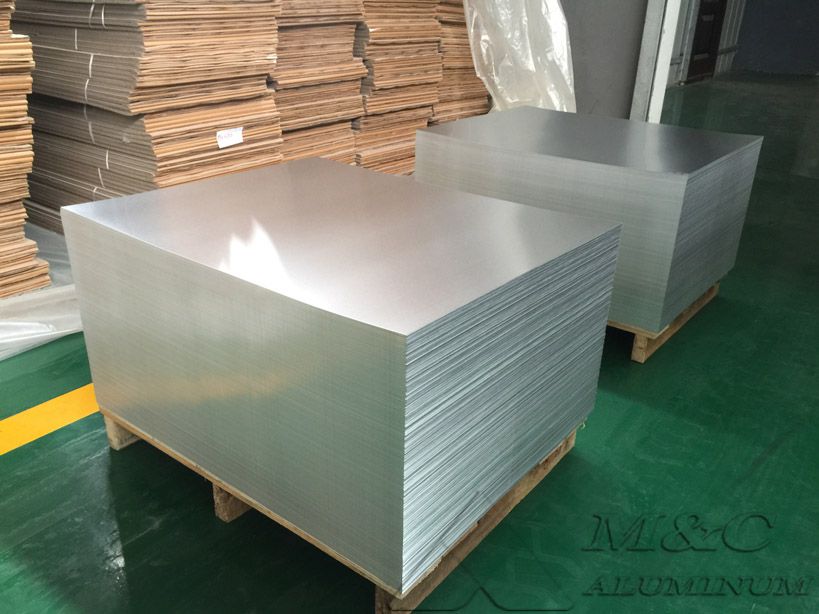

Aluminum sheet packaging for bottle caps:

There are large roll packaging and wooden box packaging.

Large roll packaging: The size of the large roll is determined by the width and length customized by the customer.

Wooden box packaging: The large size of the wooden box is determined by the size of the customized sheet material.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan