- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

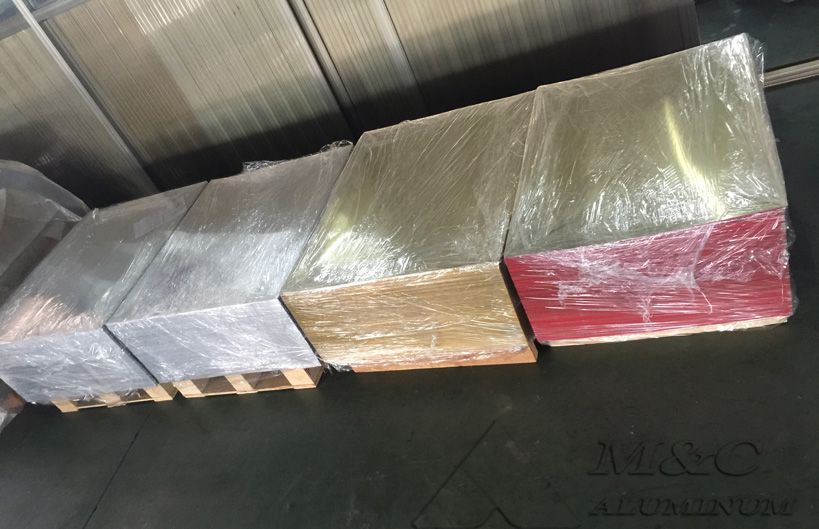

Printing aluminum bottle cap material

Printing aluminum bottle cap material mainly refers to the printing alloy material used to make bottle caps. It usually uses high-quality aluminum alloys, including 8011 aluminum foil, 1060 aluminum coil, 3105 aluminum coil, etc. These alloys have good physical properties and processing properties, which can meet the production and printing needs of aluminum bottle caps. Therefore, they are widely used in packaging in food, beverage, medicine and other industries.

Introduction of aluminum alloy bottle cap material alloy:

8011 aluminum foil: It has excellent ductility and plasticity, is suitable for making bottle caps with complex shapes, and is easy to print.

1060 aluminum coil: It has the characteristics of high elongation, excellent tensile strength, good conductivity, etc., and can meet conventional processing requirements such as stamping and stretching.

3105 aluminum coil: It belongs to the 3 series aluminum-manganese alloy, has good rust resistance and deep drawing effect, and the strength, elongation and processing performance of the material meet the production process of bottle caps with high automation intensity.

Specification requirements

The specifications of printed aluminum bottle cap materials are strict to ensure the quality and printing effect of bottle caps.

1. Thickness: Generally controlled between 0.20~0.23mm, with a tolerance of ±0.01% to ensure the sealing and strength of the bottle cap.

2. Width: Depending on the degree of automation of the production line and the design requirements of the bottle cap, the width is usually between 449~796mm.

3. Board quality: The board surface of the bottle cap material is required to be flat, without rolling marks, scratches and stains to ensure the clarity and beauty of the printed pattern.

4. Coating: The coating thickness needs to be uniform, and a coating of 3-5 microns is usually required to increase wear resistance and corrosion resistance.

Application areas:

Beverage bottles: Aluminum and aluminum alloy bottle cap materials are not only beautiful and easy to open, but also have certain anti-counterfeiting functions, which are very suitable for sealing beverage bottles.

Wine bottles: Whether it is white wine, wine or other alcoholic beverages, aluminum bottle caps can provide effective sealing and anti-counterfeiting functions to ensure the quality and safety of the wine.

Cosmetic bottles: The cosmetics industry has high requirements for packaging. Aluminum bottle caps not only have beautiful appearance, but also provide good sealing performance to protect cosmetics from external pollution.

Medicine bottles: Medicine packaging has high requirements for sealing and anti-counterfeiting. Aluminum bottle caps can meet these requirements and ensure the quality and safety of medicines.

MC Aluminum is a professional aluminum alloy bottle cap material manufacturer, producing and providing 8011 aluminum foil, 3003 aluminum alloy, 1070 aluminum plate, 5052 aluminum alloy and other products for bottle caps. The surface of the product is flat and smooth, without obvious scratches, bubbles, oxidation spots, etc. The product models are complete, factory direct sales, preferential prices, exported overseas, and after-sales service is guaranteed.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan