- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

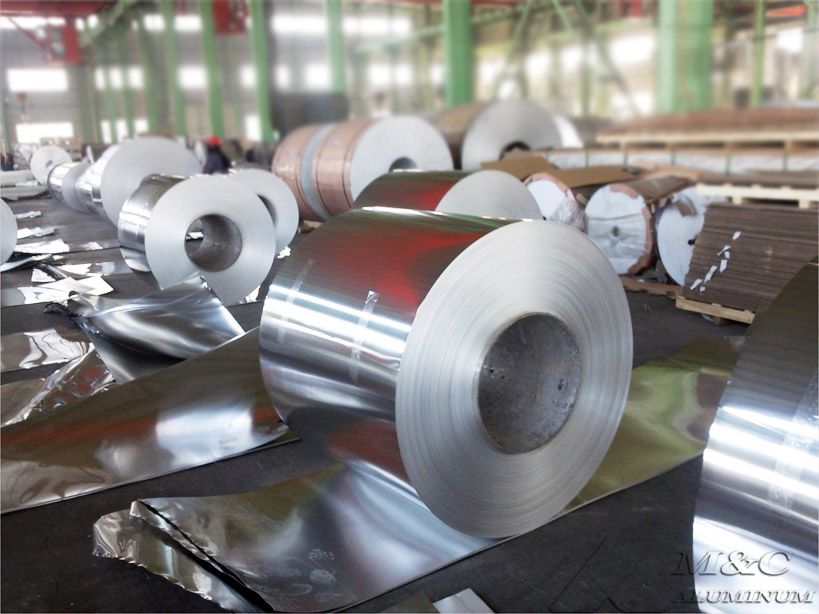

Price of 3105 aluminum coil for aluminum bottle cap

Aluminum bottle cap material is a new type of bottle cap sealing material. It is widely used in packaging of food, beverage, medicine, cosmetics and other industries because of its beautiful appearance, easy opening, and the function of preventing counterfeit goods.

Common aluminum bottle caps in daily life include aluminum-plastic combination caps, aluminum caps, screw caps, pull-ring caps, etc. The raw materials commonly used for aluminum bottle caps are 3105 aluminum coils, 3104 aluminum coils, 8011 aluminum foil, 1060 aluminum coils, etc. Among them, 3105 aluminum coils belong to the aluminum-manganese alloy series, have good anti-rust performance, and good deep drawing effect. Since aluminum bottle caps are mostly processed on production lines with high automation requirements, the requirements for material strength, elongation and processing performance are very high, and 3105 aluminum coils have excellent characteristics, and various performances meet the production requirements of bottle caps, and no creases or cracks will appear during processing.

Aluminum bottle caps have many advantages over traditional plastic bottle caps:

1. Lightweight and moderate strength: Aluminum is light and has sufficient strength to ensure the sealing performance of the bottle cap.

2. Excellent ductility and formability: Aluminum has good ductility and can be made into bottle caps of different shapes through stamping, stretching and other processes.

3. Good sealing: Not easy to leak, and the oxygen permeability and water permeability are lower after combining with aluminum foil PE pad.

4. Flexible design: Large-area fine printing, multi-color printing, side roll printing and other designs can be carried out, with easy color matching, high saturation and smoothness.

5. Low cost: The production cost is relatively low.

6. Food safety: Suitable for food packaging, high safety.

7. Environmentally friendly recycling: Aluminum materials are recyclable and meet environmental protection requirements.

How much does 3105 aluminum coil for bottle caps cost per ton?

The price of aluminum coils is composed of the price of aluminum ingots and processing fees, which varies with different aluminum plate manufacturers and specifications. Each aluminum plate manufacturer has different quotations due to differences in scale, input costs, production technology, and sales models. For products of different specifications, the prices are of course different due to different production complexities. MC Aluminum uses the same-day delivery aluminum ingot price plus processing fees and sea freight to calculate. The price of aluminum ingots can be found online and the price is transparent.

MC Aluminum is a professional aluminum bottle cap material manufacturer, providing 3105 aluminum coils, 8011 aluminum foils, 3003 aluminum plates and other aluminum alloy bottle cap materials. The product models are complete and the quality is high. They are exported to many overseas countries. They are directly sold by the manufacturer, with preferential prices and guaranteed after-sales service.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan