- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Painted aluminum alloy closure sheet 8011 3105

Painted aluminum closure sheet is a new type of bottle cap sealing material. It has exquisite appearance, strong barrier properties, easy opening, and anti-counterfeiting function. It is widely used in the sealing packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc.

There are many categories of aluminum alloy bottle cap materials produced by MC Aluminum, including 8011 bottle cap material, 5052 easy-open cap material, 3105 wine cap material, 1235 bottle cap material, 1070 cosmetic bottle cap material, etc. It has the advantages of good deep drawing performance, low ear forming rate and high strength. It is the first choice material for domestic bottle cap manufacturers and has broad prospects.

Painted aluminum closure sheet specifications:

| Alloy | 8011, 3105 |

| Temper | H14, H24, H16, H26 |

| Thickness | 0.16-0.23mm |

| Width | 500-1200mm |

| Length | 500-16000mm |

| ID | 75mm, 150mm, 300mm, 500mm, etc. |

| Technology | Hot and Cold Rolled |

| Pattern | rolling, degreasing, pre-lubricating, pre-treating, painting |

| Tensile strength | 140-145mpa |

| Yield strength | 136-137; |

| Elongation | 2.5-3.0%; |

| Perimeter rate | <2%; |

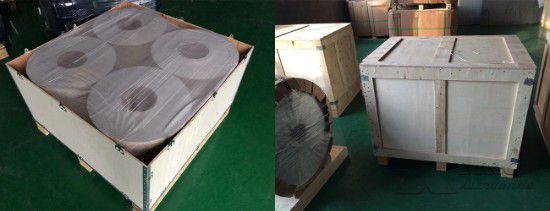

Aluminum closure sheet packaging:

Board: The board is placed in a wooden box equipped with slides along the length of the board. They are wrapped in HDPE and have hardboard on top and bottom of the stack. Iron hoop strapping runs along the length of the sheet. Put a silica gel pack inside the box to prevent moisture.

Rolls: Rolls are placed eye-to-sky or eye-to-wall on wooden pallets, wrapped with HDPE fabric and cardboard, and tied with iron hoops. Silicone bag for moisture protection.

As an aluminum alloy bottle cap material manufacturer, MC Aluminum produces 8011 aluminum foil and 3105 aluminum closure sheets with multiple advantages such as food grade, clean oil removal, fewer pinholes, good product shape, and good oxidation and coloring effects. It can undertake orders of 3-2000 tons of aluminum foil raw materials for 8011 cosmetic bottle caps. The product quality is stable, exported globally, and the price is affordable. You can purchase with confidence!

Related Articles

- Why do bottle cap aluminum closure sheet need to be oiled?

- 8011 H14 aluminum foil for chromated bottle cap materials

- 5052 3104 H19 Aluminum closure sheet for can lid

- Aluminum closures for bottle cap sealing

- 8011 3105 aluminum alloy for anti-theft aluminum screw caps

- Beer bottle cap material aluminum sheet

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan