- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Why do bottle cap aluminum closure sheet need to be oiled?

In the modern packaging industry, bottle cap aluminum closure sheet are key components of food and beverage packaging. Their quality and performance are crucial. They are widely used in beverages, medicine, cosmetics, alcohol and other fields. In order to improve the rust prevention, lubrication and stamping performance of aluminum closure sheet, DOS (dioctyl sebaceous acid) oiling process is widely used.

DOS oil, chemical name dioctyl sebaceous acid, is a colorless, odorless or light yellow transparent liquid. It has excellent rust prevention and lubrication properties and is widely used for rust prevention and lubrication of raw materials for food packaging containers. In the production process of bottle cap aluminum closure sheet, DOS oiling plays a vital role.

Features of DOS oiled aluminum closure sheet:

1. DOS oil can effectively prevent oxidation and corrosion on the surface of aluminum closure sheet. Although aluminum has the advantages of being light and corrosion-resistant, its surface may still undergo oxidation reactions in humid or corrosive environments, affecting its appearance and service life. DOS oil film can form a protective layer on the surface of the aluminum closure sheet, isolating oxygen and moisture in the air, thereby slowing down the oxidation process and extending the service life of the aluminum closure sheet.

2. DOS oil also has good lubrication properties. During the stamping and winding processes of the bottle cap aluminum closure sheet, the DOS oil film can reduce friction resistance, reduce energy consumption, and improve production efficiency. At the same time, it can also prevent the aluminum closure sheet from being scratched or damaged during processing to ensure product quality.

3. The bottle cap aluminum closure sheet needs to go through multiple processes, such as stamping, stretching, and curling. These processes have extremely high requirements on the ductility and smoothness of the material. If the friction coefficient of the aluminum closure sheet surface is too large, it will not only increase the wear of the mold, but also may cause scratches on the product surface or even processing failure. After DOS oiling treatment, the lubrication performance of the aluminum closure sheet surface is greatly improved, which can not only reduce the mold wear rate, but also reduce the friction resistance during processing, greatly improving production efficiency and product quality.

4. As a food-grade lubricant, DOS oil fully complies with the US FDA's standards for surface lubricants used in metal product manufacturing (21 CFR178.3910). Therefore, the use of aluminum closure sheet coated with DOS oil will not cause pollution to food, ensuring the health and safety of consumers. DOS oil is an environmentally friendly lubricant. During the waste treatment process, DOS oil can be quickly degraded to reduce the impact on the environment.

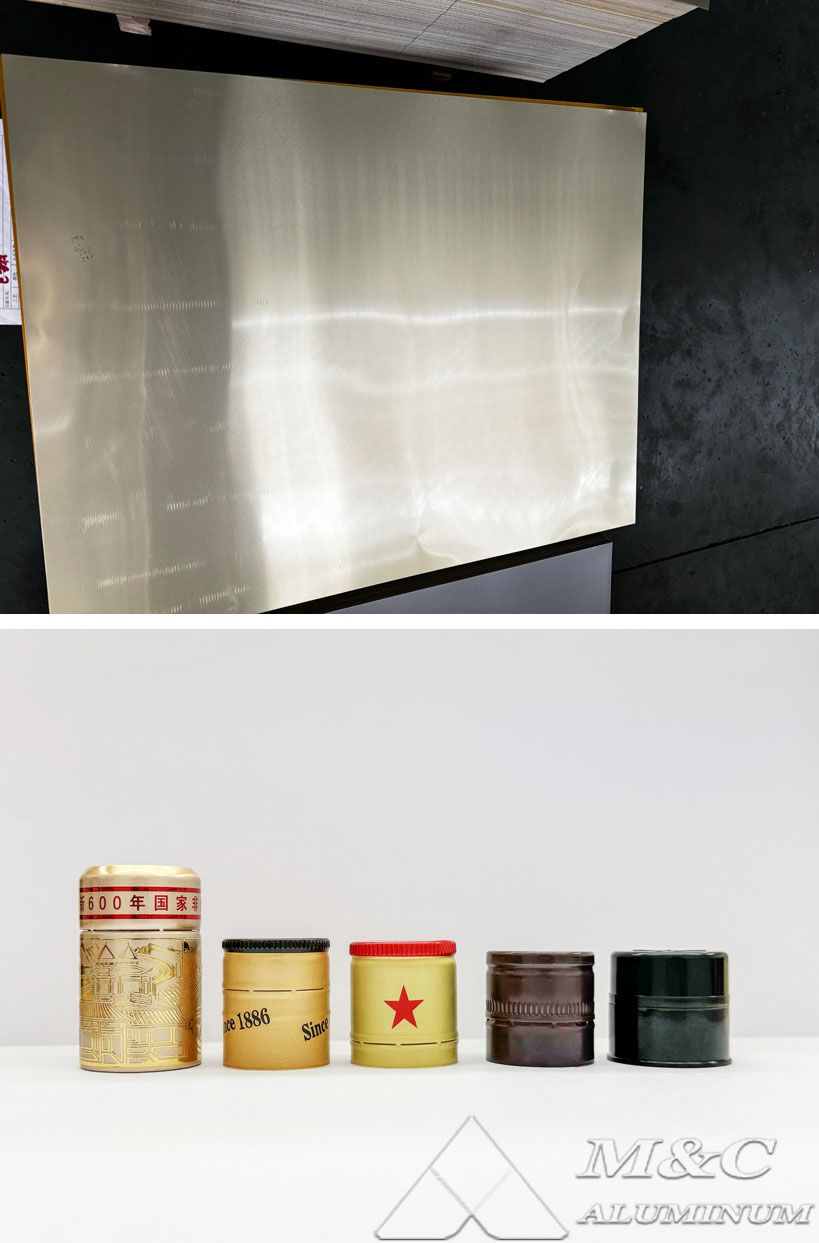

The alloys commonly used for DOS oiled coated bottle cap aluminum closure sheet include 3104, 5052, 3105 and 8011. These alloys are widely used in the manufacturing of medical bottle caps, beverage caps, cosmetic caps, wine bottle caps, etc. due to their good physical properties, processing performance, corrosion resistance and sealing.

MC Aluminum is a manufacturer specializing in the production of aluminum plates/foils/strips for aluminum bottle caps, including 1, 3, 5, 8 series aluminum alloys. The product surface is smooth, without oil stains, black silk, marks, pinholes, etc. The quality is stable and it is exported to many overseas countries. We can accept large orders of 1-200 tons with fast delivery and favorable prices.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan