- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

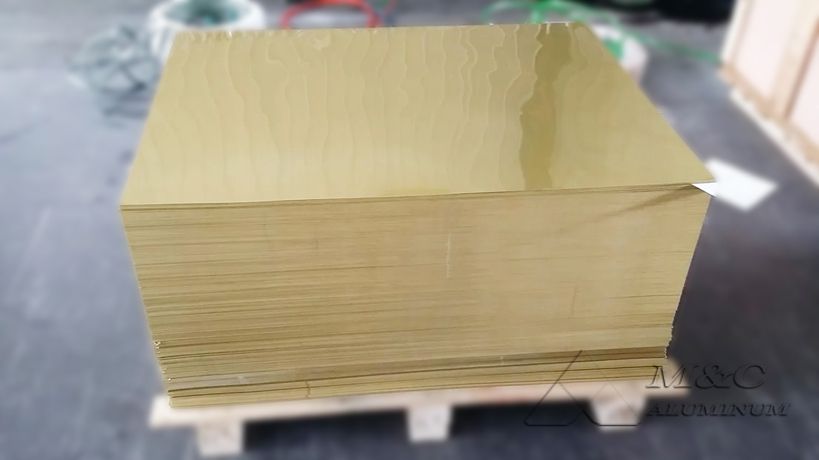

3003-H16 aluminum alloy sheet and strip for anti-theft cap

3003 aluminum alloy sheet and strip for anti-theft caps is an aluminum alloy material specially used for making anti-theft caps. It combines the excellent performance of 3003 aluminum alloy and the high strength characteristics of H16 state. It is widely used in wine, beverages (including gas, The packaging of products such as (excluding steam), pharmaceutical and health care products, meets the requirements for special processing such as high-temperature cooking and sterilization, ensuring the safety and hygiene of the products.

3003 aluminum alloy is an aluminum-manganese alloy with medium strength, good corrosion resistance, weldability and formability. Its main alloying element is manganese, with a content between 1.0 and 1.5%, which can significantly improve the strength and corrosion resistance of the material while maintaining good processing performance. In the H16 state, the 3003 aluminum closure sheet has high strength while maintaining a certain degree of toughness and ductility. It is very suitable for making parts that require a certain degree of strength and wear resistance.

Specifications of 3003 aluminum sheet for anti-theft cap:

| Temper | H16, H14, etc |

| Thickness | 0.17-0.23mm |

| Width | 800-1000mm |

| Length | 600mm --1000mm |

3003 chemical composition:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | remainder |

Features of 3003 aluminum sheet for anti-theft cap:

1.Corrosion resistance

2.High strength

3. Lightweight and easy to open

4. Easy to process and can be processed by stamping, bending and stretching.

5.Good solderability

6. Environmentally friendly and recyclable

Aluminum alloy anti-theft cap production process:

The production of 3003-H16 aluminum alloy strips for anti-theft caps usually includes steps such as smelting, casting, hot rolling, cold rolling, annealing and processing. During the production process, process parameters such as alloy composition, rolling temperature, and annealing regime need to be strictly controlled to ensure the performance and quality of the final product.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan