- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Aluminum Alloy Bottle Cap Material Thickness

With the rapid development of industries such as alcohol, beverages, medicine, and food, the demand for aluminum alloy bottle cap materials is also increasing. Especially for some high-end markets and special fields (such as medical bottle caps, milk powder easy-tear caps, etc.), the quality and performance requirements of aluminum alloy bottle cap materials are higher.

The thickness of the bottle cap material may also be affected by factors such as the shape, size, and required strength of the bottle cap. The thickness range of aluminum alloy bottle cap materials is usually between 0.15-0.5mm, with an allowable tolerance of ±0.01%. The width range is between 200-1600mm, and the width tolerance is ±1mm. The specific thickness range can vary according to different application requirements.

In specific applications, commonly used aluminum alloy bottle cap materials include 8011, 5052, 3004, 3105 and other alloy grades. Aluminum alloy bottle cap materials in different alloy states have different thickness and width requirements. For example:

The thickness of 8011 aluminum foil is 0.15-0.27mm, the width is 330-1000mm, and it is often used for wine caps, easy-pull caps, and medical bottle caps.

The state of 3003 aluminum alloy is H16, the thickness is 0.20mm~0.23mm, the width is 449mm~796mm, and it is also commonly used for aluminum bottle caps.

The thickness of 5052 aluminum alloy is 0.208-0.360mm, the width is 800-1730mm, and it is widely used in the basic caps of functional beverages.

The thickness and width of aluminum alloy bottle cap materials need to be strictly controlled during the production process to ensure the processing quality and product stability.

What are the requirements for aluminum foil for aluminum bottle caps?

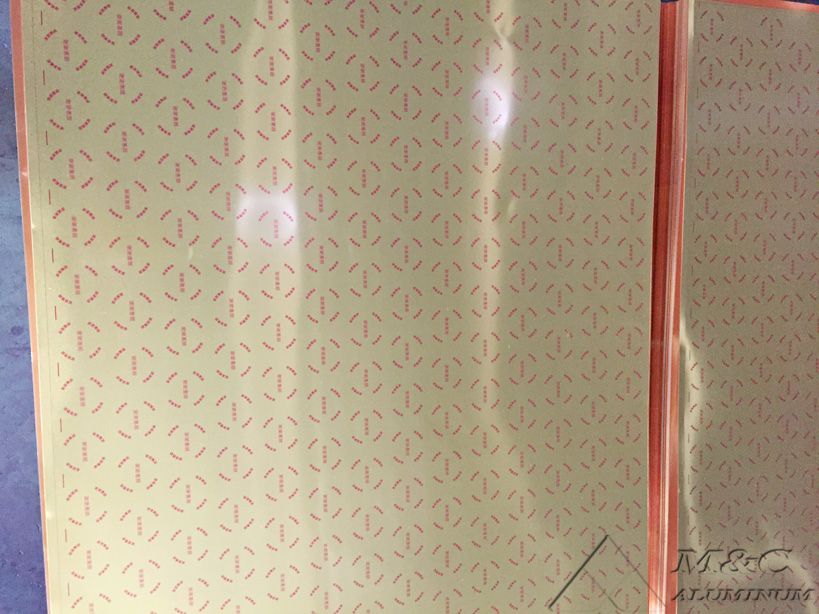

The board surface is flat and smooth, without obvious roller marks, no obvious black lines, oil spots, dust inclusions, scratches, bright strips and other defects, and the ear rate is controlled within 3%.

Features of aluminum alloy bottle caps:

1. Good sealing performance: can keep the contents fresh, prevent liquid or gas leakage, suitable for alcoholic beverages and pharmaceutical products.

2. Easy to open: the design takes user convenience into consideration, and the easy-pull cap design makes opening the bottle cap simple and quick.

3. Lightweight and durable: aluminum alloy material is light and strong, not easy to deform or break, and reduces the weight of packaging.

4. Anti-corrosion: good corrosion resistance and oxidation resistance, extending the shelf life of the product.

5. Environmentally friendly and recyclable: reusable, simple recycling process, conducive to resource recycling.

MC Aluminum's aluminum bottle caps are made of 8011 aluminum foil, 5052 aluminum closure sheet, 3003 aluminum alloy, etc., with multiple advantages such as food grade, clean degreasing, few pinholes, and good product plate shape. The product quality is stable, the manufacturer sells directly, and it is exported to many countries and regions overseas, and is deeply trusted by customers.

Related Articles

- 8011 3105 aluminum alloy for anti-theft aluminum screw caps

- 8011 Aluminum Sheets, Strips, and Foils for Bottle Caps

- Twist-off anti-counterfeiting aluminum alloy cover

- Aluminum foil for poe cap 8011 1050

- 3003-H16 aluminum alloy sheet and strip for anti-theft cap

- Printed Aluminum Closure Sheet for Anti-Theft Caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan