- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

What are the raw material requirements for aluminum covers?

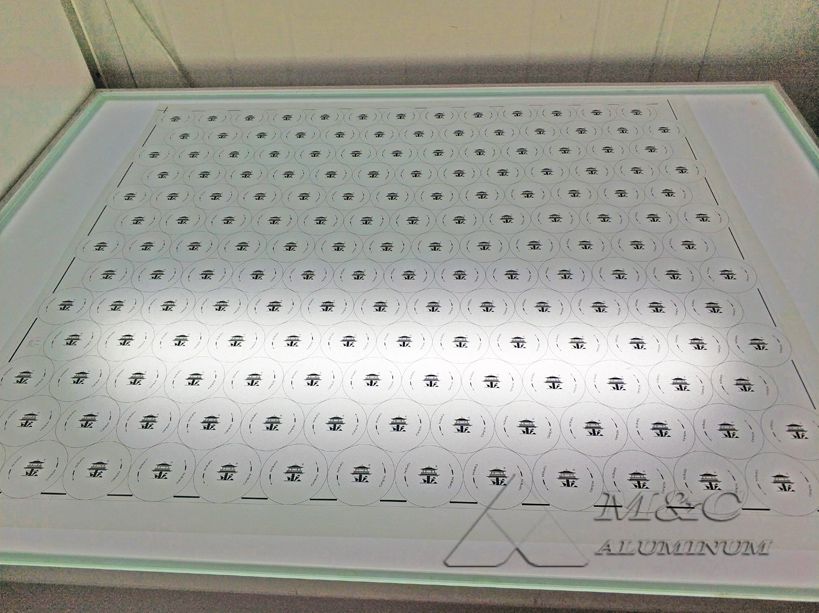

In our daily life, many products require bottle caps, such as cosmetics, medicine, alcohol, beverages, canned foods, etc. Aluminum bottle cap materials have good colsure performance, strong tensile strength, corrosion resistance, and exquisite appearance. And it can be recycled, becoming a trend in the market.

Aluminum colsure sheet is an important raw material for aluminum cover manufacturing. Aluminum sheet is characterized by light weight, high strength, good corrosion resistance, recyclability, etc. It is widely used in packaging, construction, electronics and other fields. The production of aluminum sheets generally adopts the rolling process. After the raw aluminum ingots are first smelted, they are rolled and deformed on the rolling mill to make aluminum sheets of the required thickness and width.

Since aluminum covers are mostly processed on production lines with a high degree of automation, the strength, elongation and dimensional deviation of the material are very strict, otherwise cracks or creases will occur during deep drawing. In order to ensure that the bottle cap is easy to print after it is formed, the aluminum surface of the bottle cap material is required to be flat and free of rolling marks, scratches and stains.

What are the requirements for processing aluminum alloy bottle cap materials?

1. Width and thickness tolerances shall be implemented according to the requirements of the process card

2. The surface is smooth, without defects such as cracks, bubbles, through-holes, metal and non-metal press-in, light and dark streaks, etc.

3. During the rolling process, the surface quality shall be randomly checked at least every 3 rolls, and the surface quality of each roll of the finished product shall be checked.

4. The aluminum alloy bottle cap material is required to be free of burrs, knife back prints and ruffles.

As a professional aluminum bottle cap material manufacturer, MC Aluminum specializes in the production of aluminum sheets, aluminum foil, aluminum coils, etc. for bottle caps, including 8011, 1060, 1235, 3105 and other alloys. It has high product quality, advanced technology and equipment, and mature production processes. Meet the manufacturers' requirements and needs for aluminum alloy bottle cap materials, direct sales from manufacturers, and preferential prices.

Related Articles

- 3105 H14 / H16 Aluminum Closure Sheet for Screw Caps

- 3105 8011 printed aluminum plate for bottle cap anti-counterfeiting

- Pilfer proof cap closure aluminum foil 8011

- Aluminum foil for painted POE cover 8011 1050

- High quality requirements for aluminum plates for bottle caps

- Standards for aluminum plates for bottle caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan