- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

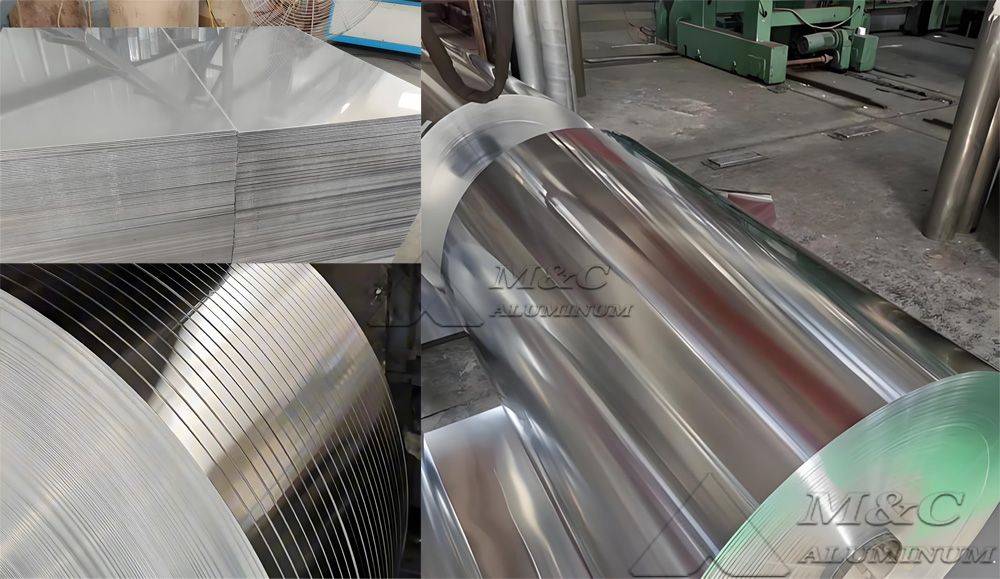

8011 Aluminum Sheets, Strips, and Foils for Bottle Caps

8011 aluminum alloy is a premium material specially designed for the packaging industry. Thanks to its unique properties, it has taken a dominant position in applications such as bottle caps, cap liners, and bottle neck seals. Whether in sheet, coil, or foil form, 8011 aluminum alloy can meet the high standards of production and safety requirements.

8011 aluminum alloy belongs to the 8xxx series, with iron (Fe) and silicon (Si) as the main alloying elements. It offers excellent deep-drawing performance and ductility, along with high strength and corrosion resistance, making it ideal for cap forming and subsequent printing and coating. 8011 aluminum material is available in various tempers such as O, H14, H16, and H18.

Common tempers:

O temper (annealed soft state): Features extremely high plasticity, suitable for deep drawing and complex shaping of bottle caps.

H14/H16/H18 tempers (work-hardened state): Process-hardened to provide higher strength and hardness, suitable for bottle caps that need to retain shape and strength.

8011 aluminum foil is commonly used for liquor bottle caps, wine bottle caps, cosmetic caps, milk powder lids, pharmaceutical closures, beverage closures, and yogurt lids.

8011 Aluminum Sheet/Strip/Foil Product Information

| Alloy | 8011 |

| Temper | O, H14, H16, H18, etc. |

| Aluminum foil | Thickness 0.01-0.2 mm (0.15-0.27 mm commonly used for cap material), width 100-1700 mm. |

| Aluminum strip/sheet | Thickness 0.15-0.5 mm (pharmaceutical cap material), width 330-1000 mm, tolerance ±0.005 mm. |

| Length | Customized |

| Tensile strength | 150-165 MPa |

| Elongation | ≥2% |

| Earring rate | ≥3% |

| Surface cleanliness | Smooth and bright, free from color difference, pores, scratches, and oil stains. |

| Applications | Used for producing pilfer-proof caps (ROPP caps), screw caps, pharmaceutical bottle caps, and small bottle seals. |

| MOQ | 1-3 tons |

Advantages of 8011 Aluminum Sheet/Strip/Foil for Caps

Excellent processability: Suitable for deep drawing, stamping, embossing, printing, coating, and other processes.

Strong corrosion resistance: Can be in long-term contact with beverages and food without corrosion.

Good decorative appearance: Easy to apply color printing and anodizing, enhancing product grade.

Eco-friendly and recyclable: Meets the green packaging trend with a high recycling rate.

Reliable sealing performance: Ensures the taste and quality of the liquid inside the bottle.

Application Types of 8011 Aluminum for Bottle Caps

8011 H14, H16, H44, H46 Aluminum Closure Sheet for ROPP Caps

8011 aluminum closure sheets have good formability, excellent earring rate, and flatness, ensuring deep drawing of long caps. They are widely used to make ROPP caps for wine bottles and other beverage bottles. These materials are precisely rolled and slit to ensure high flatness and low earring rates, enabling stable performance on high-speed stamping production lines and reducing material waste.

8011 H16/H14 Aluminum Sheet, Strip, and Foil for Small Bottle Seals

Modern aluminum bottle caps are generally made from 8011 H16/H14, then coated with epoxy varnish or various colors such as yellow, gold, red, blue, and black. This enhances sealing performance, prevents leakage, and provides additional anti-counterfeiting functions. The excellent heat-sealing performance of 8011 aluminum foil allows it to bond firmly with various container materials.

8011 aluminum sheet for Omnia screw-on caps

Omnia aluminum caps are relatively shallow and are typically made from single-annealed 8011 cast aluminum. To maintain a good seal, the inner surface of the 8011 aluminum sheet is coated with a clear varnish to ensure a perfect bond between the Omnia cap and the inner plastic liner.

Typical closure applications include aluminum easy-open ends, easy-open can lids, easy-open can components, and aluminum pull rings.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan