- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Which Aluminum Sheets Are Suitable for Wine Bottle Caps

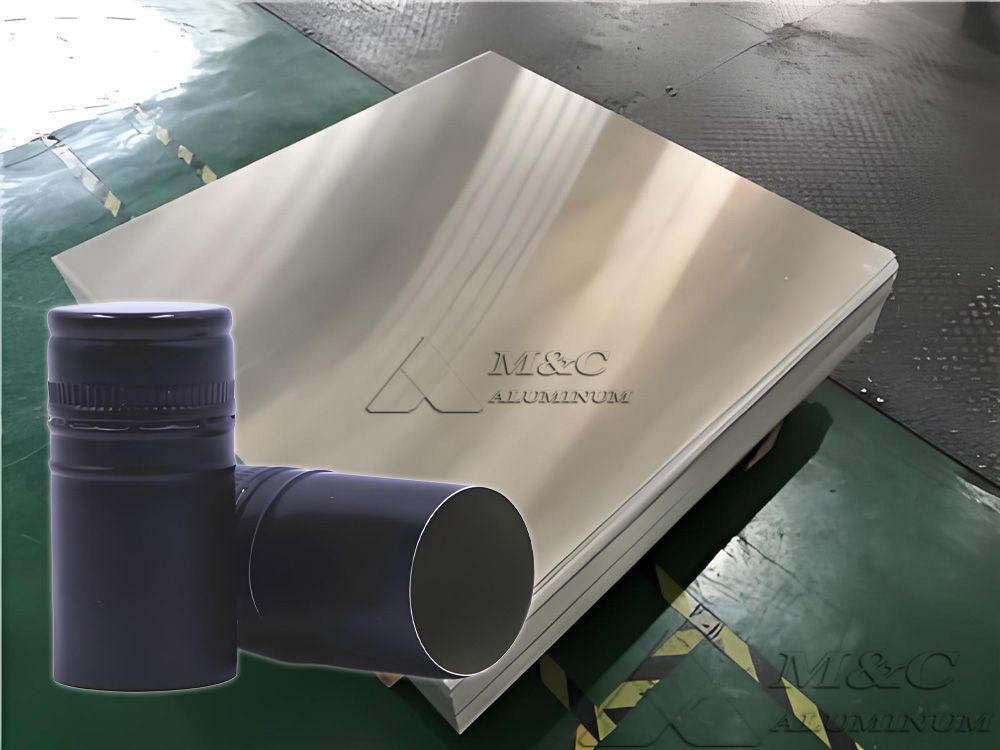

Nowadays, wine bottles predominantly use screw caps instead of traditional cork stoppers. These aluminum screw caps offer excellent oxygen barrier properties, preventing wine oxidation, preserving freshness and aroma, and avoiding issues related to cork taint.

Aluminum sheets used for wine bottle caps (especially 30x60mm screw aluminum caps) are typically referred to as aluminum closure sheets. They must meet high standards for formability, printability, stamping performance, and food safety.

Main Aluminum Alloys Used for Wine Bottle Caps

1. 8011 Aluminum Alloy Sheet

This is the most widely used aluminum material for bottle caps. It offers excellent processability, deep-drawing properties, and a low earing rate. It is particularly suitable for printing and anodizing processes. Typically supplied in H14, H16, or H18 tempers, it strikes a good balance between strength and formability, making it the mainstream choice for 30x60mm wine screw caps.

2. 3105 Aluminum Sheet

Slightly stronger than 8011, 3105 provides better corrosion resistance, deep drawing performance, and oxidation resistance. Its surface is ideal for multicolor printing and high-end decorative finishes. Often used for premium wine caps, it is also supplied in H14 and H16 tempers, and is favored by brands with higher requirements for appearance and sealing performance.

3. 1060 and 1050 Aluminum Sheets

These are high-purity aluminum grades with excellent ductility, ideal for deep-drawing into irregular or specially structured caps, such as for cosmetic or pharmaceutical aluminum-plastic closures. However, due to their relatively low strength, they are mostly used in special packaging or low-pressure applications.

4. 3003 Aluminum Sheet

With performance between pure and alloyed aluminum, 3003 offers good corrosion resistance and moderate strength. It is suitable for general-purpose printed caps and is also often used for inner caps and gaskets.

5. 5182 Aluminum Sheet

A high-strength aluminum-magnesium alloy, commonly used in beer can tabs and easy-open lids, where high mechanical strength is required. Though rarely used in wine caps, it may be selected for function-oriented caps that demand exceptional sealing strength.

Common Tempers (Hardness Levels) for Closure Aluminum Sheets

H14 / H16 / H18: Partially hardened tempers suitable for printing, hot stamping, and subsequent forming without deformation.

O Temper (Soft): Ideal for deep-drawing and high-deformation processes.

H19: High-strength temper used in pressure-resistant packaging but rarely applied to wine caps.

Why Choose Aluminum Sheets for Wine Screw Caps?

Excellent Workability: Aluminum sheets are highly ductile, ideal for deep drawing, rolling, and forming processes, especially for precision thread sealing.

Strong Sealability: Aluminum caps with food-grade liners effectively prevent oxidation and contamination, extending wine shelf life compared to cork.

Tamper Evidence & Branding: Aluminum surfaces allow for easy printing and decoration, enhancing brand identity and ensuring tamper resistance.

Eco-Friendly & Recyclable: 100% recyclable, aluminum meets sustainability trends and is more environmentally friendly than plastic alternatives.

Corrosion Resistance: High-quality aluminum alloys resist corrosion, making them suitable for long-term storage and international transport without rust or leakage.

Cost-Effective: With controllable cost, compatibility with various bottle types, and ease of automated capping, aluminum caps are widely used for mid-to-high-end wines.

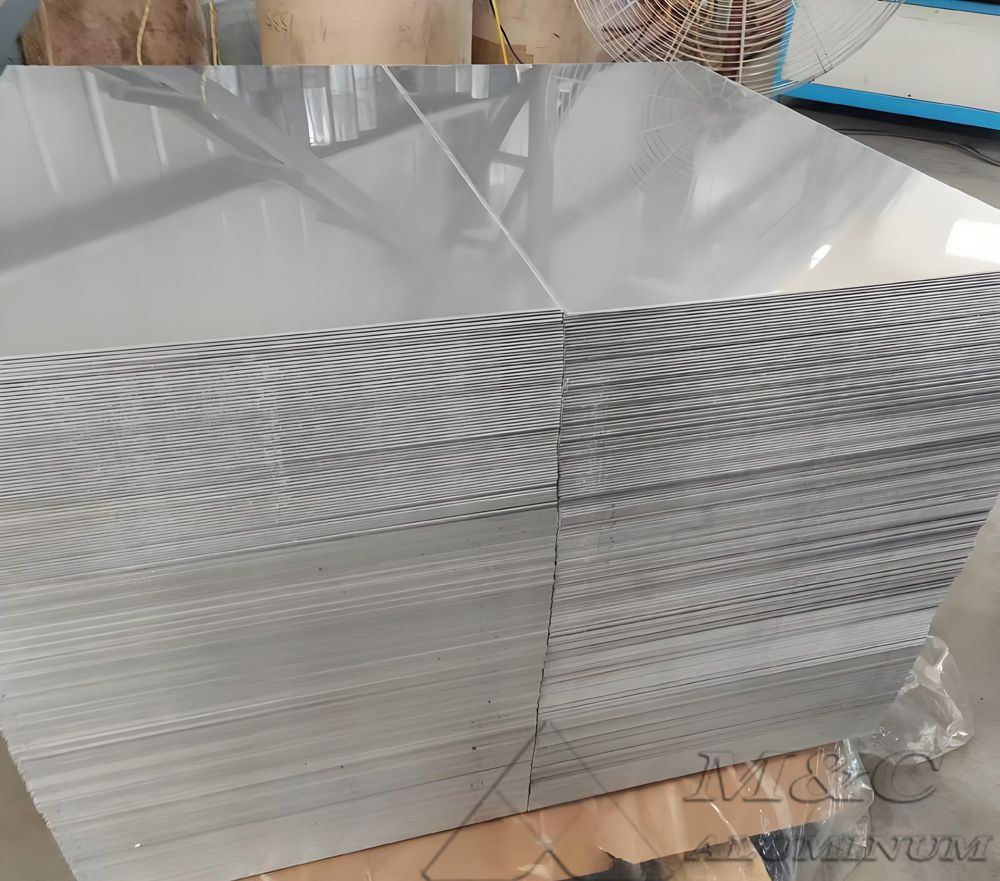

Technical Specifications of Aluminum Closure Sheets for Wine Caps

| Alloys | 8011, 3105, 3003, 1060, 1070, 5182, etc. |

| Tempers | H14, H16, H18, etc. |

| Thickness | 0.15mm - 0.23mm (typical wine cap thickness: 0.20mm) |

| Width | 200mm - 1000mm |

| Length | 1000mm - 16000mm |

| Surface treatments | Phosphating, anodizing, coating, printed layers |

| Coating types | Polyester, epoxy, food-safe coatings |

| Printing compatibility | Suitable for UV printing, screen printing, hot stamping |

| Stamping performance | No edge cracks, no wrinkles, uniform deep drawing |

| Samples | Available |

| MOQ | 1-3 tons |

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan