- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

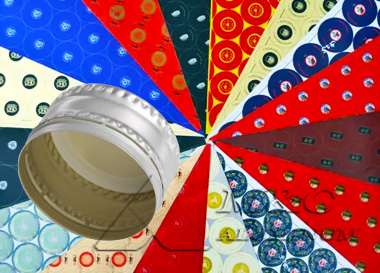

3105 Aluminum Closure Sheet for Beverage Container Caps

2025-05-09

The 3105 closure sheet features excellent deep-drawing performance, with material strength, elongation, and processability meeting the requirements of automated cap manufacturing processes.

Best Aluminum Alloys for ROPP Bottle Caps

2025-06-13

In the production of ROPP (Roll-On Pilfer-Proof) bottle caps, the selection of aluminum alloy must take into account deep-drawing performance, corrosion resistance, cost-efficiency, and food safety compliance.

1060 3105 5052 8011 Aluminum Closure Sheet for Bottle Caps

2025-09-29

Bottle cap aluminum closure plates are usually made of 1060, 3105, 5052 and 8011 aluminum alloys, which have the advantages of light weight, corrosion resistance and good formability.

Coated Aluminum Foil for closure lid

2025-04-22

Bottle cap aluminum foil typically uses 8011 aluminum alloy (such as H14, H16, H18 temper) with a thickness range of 0.006-0.5mm.

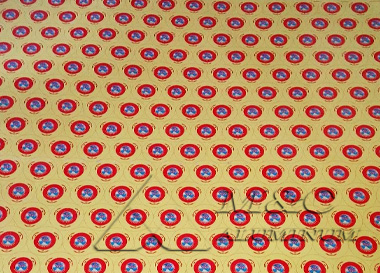

Chromium-Plated and DOS-Treated Aluminum Sheets for Cosmetic Bottle Caps

2025-08-15

Chromium plating and DOS treatment are two common aluminum sheet surface processing techniques widely used in manufacturing premium cosmetic bottle caps.

Aluminum Alloy Sheets for Beverage Bottle closure Caps

2025-04-11

In the modern beverage packaging industry, the choice of bottle caps is crucial. With increasing consumer demands for quality, environmental sustainability, and safety, aluminum alloy sheets have become the material of choice for bottle caps due to their

3105 Aluminum Sheet for Closures, Bottle Caps, and ROPP Caps

2025-08-22

3105 aluminum sealing plates are lightweight, corrosion-resistant and have good formability, so they are widely used in wine bottle caps, beverage bottle caps, cosmetic bottle caps, etc.

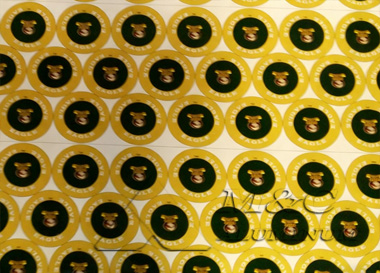

Chromized Aluminum Sheet for Aluminum Bottle Cap

2025-09-26

The 1/3/5/8 series aluminum sealing sheets produced by MC Aluminum are mainly used in the bottle cap market and are widely popular due to their light weight, excellent deep drawing performance and good sealing effect.

Hot-Rolled 3105 Aluminum Sheet for Bottle Caps

2025-08-26

While maintaining excellent ductility and plasticity, 3105 aluminum sealing plate has better corrosion resistance and surface coating performance, which is very suitable for bottle cap manufacturing processes such as deep drawing and stamping.

Features of 8011 Aluminum Alloy for Oral Liquid Bottle Cap Material

2025-07-15

8011 aluminum alloy has become the mainstream choice for oral liquid aluminum caps due to its unique performance advantages.