- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Chromized Aluminum Sheet for Aluminum Bottle Cap

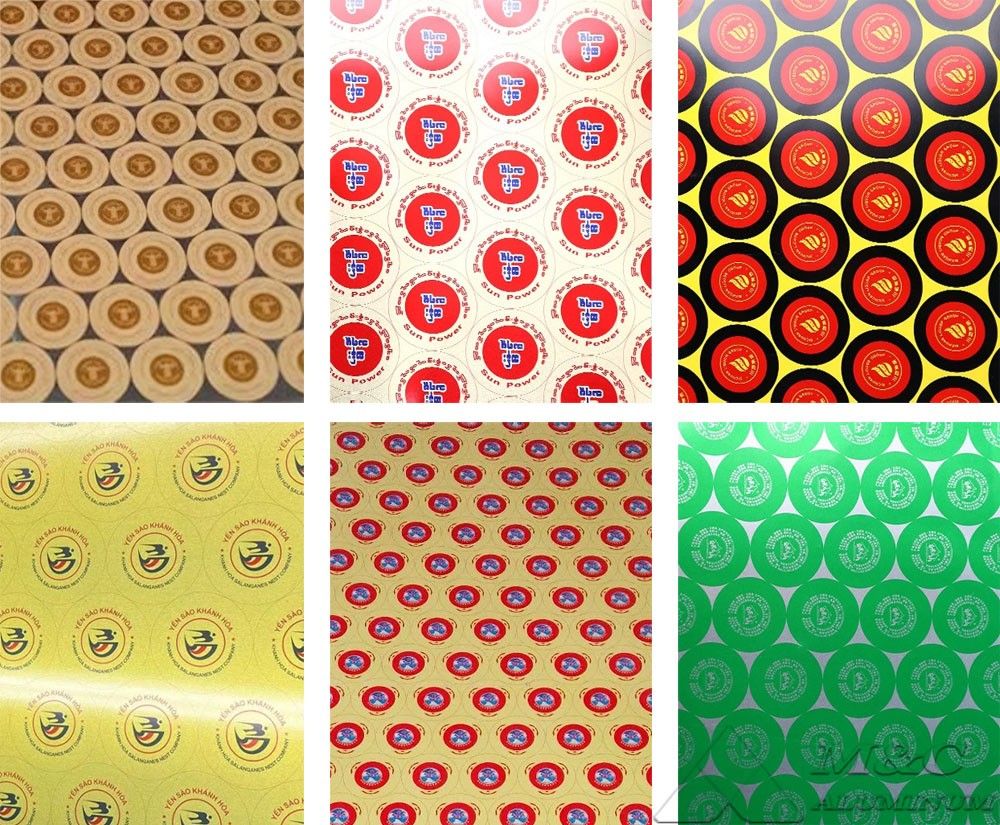

MC Aluminum produces 1/3/5/8 series aluminum closure sheets mainly for the bottle cap market. Owing to their lightweight, excellent deep-drawing performance, and superior sealing effect, these products are highly popular. With unique rolling technology, MC Aluminum offers ideal aluminum sheets for manufacturing long-neck wine bottle caps, ROPP caps, and a variety of pilfer-proof closures (for beverage bottles, soft drinks, juices, and energy drinks).

The surface treatment options for aluminum cap sheets include color coating, chromate phosphate coating, and DOS treatment. These provide a low earing rate, significantly reducing waste and improving production efficiency.

What is Chromized Aluminum Sheet?

Chromized aluminum sheet is a functional material manufactured by applying an electrochemical chromizing process to the surface of high-quality aluminum alloy substrates (8011/3105). After chromizing, the aluminum sheet forms a dense and uniform protective film, consisting of:

Aluminum substrate: provides lightweight properties, high ductility, and strength, suitable for deep drawing.

Metal chromium layer: high hardness, wear resistance, and corrosion resistance, protecting the base material and extending cap lifespan.

Hydrated chromium oxide layer (outer layer): porous structure, enabling subsequent printing or coating, improving adhesion.

Key Features of Chromized Aluminum Sheet

1. High corrosion resistance: the chromium layer effectively blocks air and moisture, preventing oxidation and rust.

2. Excellent gloss: bright metallic appearance with mirror or semi-mirror effect, enhancing visual appeal.

3. Strong adhesion: the chromium layer is firmly bonded to the aluminum sheet, resistant to peeling.

4. Good workability: retains aluminum’s lightweight, ductility, and formability, suitable for deep drawing and spinning.

Product Information for Aluminum Cap Sheets

| Alloy grades | 8011-H14, 8011-H16, 3105-H16, 3105-H18 |

| Thickness range | 0.15mm - 0.30mm |

| Width range | 200mm - 1600mm, customizable |

| Length range | 100mm - 6000mm, customizable |

| Surface treatments | chromizing, DOS treatment, color coating, printing, clear lacquer protection |

| Applications | ROPP caps, screw caps, pilfer-proof caps, small bottle seals |

| Samples | available |

| Packaging | standard seaworthy packaging |

| MOQ | 1-3 tons |

Why Choose Chromized Aluminum Sheet for Cap Manufacturing?

Lightweight: aluminum is lightweight, reducing transportation costs.

Corrosion resistance: chromium layer resists attack from acidic beverages, alcohol, and other contents.

Formability: excellent ductility (elongation ≥ 5%), resistant to cracking or wrinkling during deep drawing, ideal for complex threads and pilfer-proof rings.

Aesthetic appeal: compared with standard aluminum sheets, chromized sheets are more scratch-resistant and maintain brightness for longer.

Eco-friendly: 100% recyclable aluminum; the chromizing process avoids heavy metal coatings and meets food-contact standards.

Application Fields of Chromized Aluminum Sheets

Wine & spirits packaging: pilfer-proof caps for wine, liquor, and spirits bottles.

Beverage sealing: closures for carbonated drinks, juices, and mineral water.

Pharmaceutical packaging: medical bottle caps, plastic-aluminum composite closures.

Cosmetics industry: perfume caps, essential oil caps, and other premium packaging.

Comparison with Other Materials

vs. Tinplate (tin-coated steel): Tinplate caps are heavier, and the tin coating is relatively soft, with lower wear resistance and gloss retention compared to chromized aluminum sheets. Aluminum caps are lighter and more cost-competitive.

vs. Standard aluminum sheet: Standard aluminum sheets are softer, prone to oxidation and dulling, and require coating for use. Chromized aluminum sheets inherently provide both decorative appeal and protection.

Related Articles

- 8011 H16 H14 aluminum strip suitable for vial closure

- Aluminum bottle cap production process

- Aluminum Anti-Theft Cap Raw Material Manufacturer

- Color-coated aluminum closure sheet for bottle caps

- Aluminum Alloy Bottle Cap Material: 3105 Aluminum Coil

- High quality requirements for aluminum plates for bottle caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan