- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

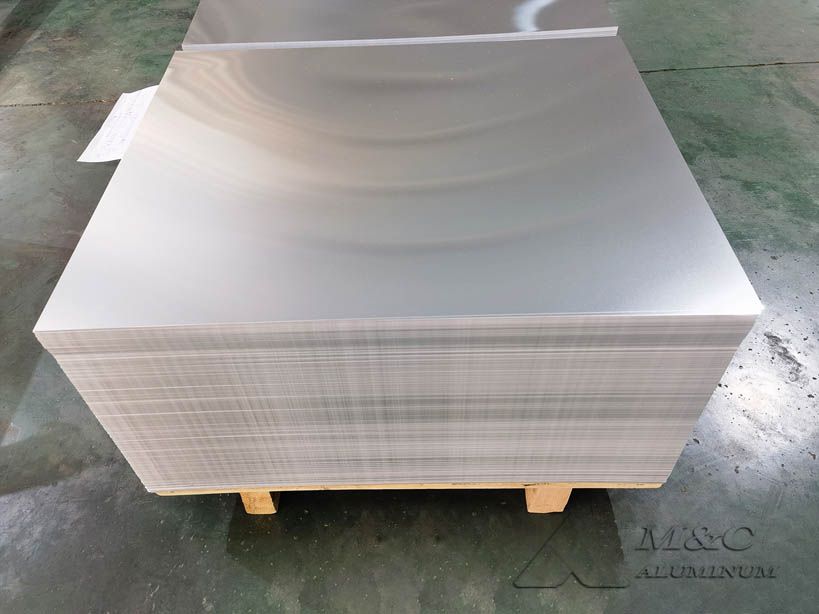

Aluminum screw cap core material

Aluminum closures, also known as aluminum roll-on thread caps, are manufactured through a deep-drawing process. In this process, a flat aluminum disc is stamped into a mold to form the bottle cap shape. The closure is then coated or further processed to enhance its corrosion resistance and improve its appearance. Aluminum closures are primarily used for sealing glass or plastic bottles with threaded necks.

Introduction to the core material of aluminum screw cap:

Aluminum closures typically use high-purity aluminum alloys as core materials, such as 8011, 3105, 1060, and 5052 series aluminum. These alloys provide excellent stamping and forming properties, high strength, and superior oxidation resistance, ensuring the stability and durability of bottle caps during both opening and sealing.

Common Aluminum Alloys and Their Features

8011 Aluminum Alloy: Commonly used in food and pharmaceutical packaging, offering excellent moisture resistance and oxidation resistance. Ideal for high-end bottle closures.

3105 Aluminum Alloy: Higher strength and superior corrosion resistance, widely applied in carbonated beverage, alcoholic drink, and pharmaceutical packaging.

1060 Aluminum Alloy: High purity and excellent ductility, suitable for closure applications requiring greater flexibility.

5052 Aluminum Alloy: High strength and superior corrosion resistance, making it ideal for premium alcohol, pharmaceutical, and cosmetic bottle caps.

Technical Specifications

| Alloy | 8011, 3105,1060,5052 |

| Temper | H14, H16, H24, H26 |

| Thickness | 0.15~0.25 mm (+/-0.005mm) |

| Width | 500~1000 mm (+0.5mm, -0mm) |

| Length | 500~1000 mm (+0.5mm, -0mm) |

| Coil Width | 500~1000 mm |

| Strip Width | 20~500 mm |

| Earing Rate | 1% |

| Diagonal Tolerance | ≤ 1mm |

Performance advantages of aluminum screw cap:

Food & Beverage

Wine & Spirits: A replacement for traditional cork stoppers, preventing cork taint (TCA) and random oxidation, ensuring stable wine quality.

Beverages & Mineral Water: Suitable for sealing carbonated and non-carbonated drinks such as soda, juices, and bottled water.

High-Temperature Sterilized Products: Used for products requiring high-temperature steam sterilization, such as bird’s nest beverages, coffee, and dairy drinks.

Other Sectors

Pharmaceuticals: Ensures airtight sealing and product stability for medical bottle closures.

Cosmetics: Applied to lipsticks, perfumes, and other beauty products, offering an elegant appearance and secure closure.

Chemical Industry: Used in hazardous chemical packaging to prevent leaks and ensure safety.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan