- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

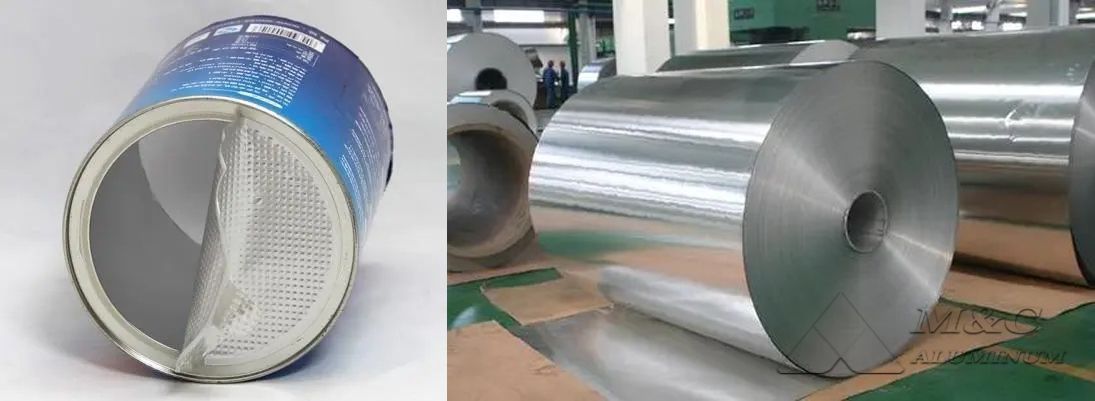

8011 heat-sealed aluminum foil for easy-peel milk powder can lid

The 8011 aluminum foil produced by MC Aluminum has excellent heat-sealing properties, good moisture and corrosion resistance, and high barrier properties. This kind of aluminum foil is usually coated or compounded with different heat-sealing layer materials, so that it can be firmly adhered to the milk powder can, and at the same time it is easy to tear open, making it convenient for users to take the product. Especially in the packaging of milk powder, infant formula milk powder, coffee powder and other products that need to maintain high quality and safety. It can not only maintain the freshness and nutritional content of the product, but also provide convenience when using it.

Heat-sealed aluminum foil for milk powder cap specifications:

| Alloy | 8011 |

| Temper | O |

| Thickness | 0.04-0.09mm |

| Width | 100-1600mm |

| Length | 100-16000mm |

8011 chemical composition(%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Al |

| 8011 | 0.5-0.9 | 0.6-1.0 | ≤0.10 | ≤0.20 | ≤0.05 | ≤0.05 | - | ≤0.10 | ≤0.08 | - | Remainder |

Advantages of aluminum foil cap for milk powder cans:

1. Extend shelf life: Due to the high barrier properties of 8011 heat-sealed aluminum foil, it can effectively extend the shelf life of milk powder and other products, and maintain the freshness and quality of the products.

2. Improve the packaging grade: Aluminum foil packaging gives people a high-end and exquisite feeling visually, which helps to improve the market competitiveness and brand image of the product.

3. Convenient to open and store: The aluminum foil or tin foil on the milk powder can cap usually adopts an indentation design, which is convenient for consumers to tear it along the indentation for use. At the same time, folding it in half after tearing it can prevent the milk powder from getting damp and agglomerating.

Why choose MC Aluminum?

1. The board surface should be flat, without bright lines, roller marks, spots, small black silk, scratches, pinholes, and concave and convex spots.

2. The thickness of the finished product should be controlled within ±4%.

3. Strictly control the processing technology of aluminum foil.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan