- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

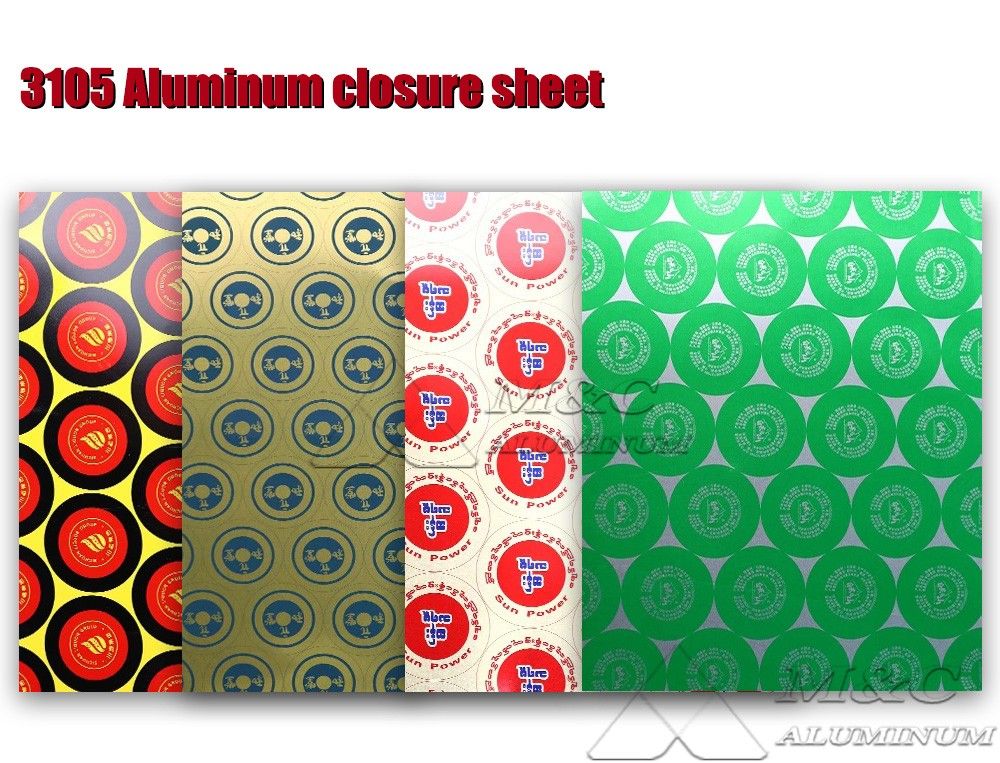

3105 H14 / H16 Aluminum Closure Sheet for Screw Caps

What is 3105 H14 / H16 Aluminum Closure Sheet?

3105 aluminum alloy is an Al-Mn series alloy, classified as an anti-rust aluminum series. It provides excellent corrosion resistance, which is particularly critical for protecting packaging contents such as wines, beverages, and foods.

In the annealed state, 3105 aluminum closure sheet has high plasticity, and even in a semi-cold worked state, it retains good formability. This makes it an ideal choice for deep drawing processes required in screw cap production.

MC Aluminum produces 3105 aluminum sheets with thicknesses ranging from 0.1mm to 500mm, widths from 100mm to 2650mm, and most commonly supplied in H14 and H16 tempers, suitable for a variety of screw cap manufacturing needs.

H14 temper: Semi-cold work hardened, offering moderate strength and good formability.

H16 temper: Higher degree of cold work hardening, providing greater strength.

3105 H14 is suitable for deep-drawing complex bottle caps, while H16 is more suitable for high-strength applications. The material surface is pre-treated to improve lubrication and coating adhesion, enhancing stamping efficiency.

Mechanical Properties of 3105 H14 / H16 Aluminum Closure Sheet

| Property | H14 Temper | H16 Temper |

| Tensile Strength (MPa) | 110-145 | 145-165 |

| Yield Strength (MPa) | 90-120 | 120-140 |

| Elongation (%) | 3-5 | 2-4 |

| Earing Rate (%) | ≤3 | ≤3 |

3105 Bottle Cap Aluminum Sheet Product Information

| Alloy | 3105 |

| Temper | H14 / H16 |

| Thickness | 0.15mm - 0.3mm |

| Width | 200mm - 1600mm |

| Length | 100mm - 6000mm |

| Surface treatment | Color coating, anodizing, cleaning, protective film |

| Sample | Available |

| Packaging | Standard export wooden cases |

| MOQ | 1-3 tons |

Key Properties of 3105 H14 / H16 Aluminum Closure Sheet

1. Corrosion Resistance

Naturally forms an oxide film that resists acid beverages, alcohol, etc., ensuring product safety and maintaining cap appearance. Food-grade, non-toxic, and eco-friendly.

2. Strength and Formability

Balances strength and ductility, ensuring screw caps remain rigid during transport and use, yet easy to process.

3. Lightweight

Density is only one-third that of steel, reducing packaging weight while maintaining performance.

4. Excellent Deep Drawing & Low Earing Rate

Outstanding deep-draw ability with low earing rate (≤3%), reducing material waste and ensuring stable threading and sealing performance.

5. Safety & Sustainability

100% recyclable, non-toxic, safe for direct food contact, aligning with green development trends.

6. Printing & Decoration

Smooth surface, ideal for color printing, coatings, and anodizing. Supports branding, anti-counterfeiting, and premium decoration.

Typical Applications

Beverage Caps: Carbonated drinks, mineral water, juice bottles-requiring tight sealing and high pressure resistance.

Wine & Spirits Closures: H16 sheets ensure long-term stability and leakage prevention.

Pharmaceutical Caps: Meets strict hygiene and safety standards.

Cosmetic & Personal Care Caps: Perfume, essential oils, cosmetics-where premium appearance and anti-counterfeiting are key.

Manufacturing Process

1. Casting: Aluminum ingots and alloying elements melted and homogenized.

2. Hot & Cold Rolling: Sheets rolled to target thickness with enhanced mechanical properties.

3. Annealing & Tempering: Achieves H14 or H16 states, balancing strength and formability.

4. Surface Treatment: Brushing, anodizing, color coating, or film lamination as required.

5. Inspection & Slitting: Rigorous testing of thickness, strength, and surface quality to meet closure standards.

Strict Surface Quality Requirements

Smoothness: Flat, glossy surface without scratches, dents, or oxidation marks-essential for high-quality printing.

Cleanliness: Free from oil, dust, or impurities that may impair ink adhesion.

Uniform Thickness: Strict tolerance control prevents cracking or deformation during forming.

Flatness: No waves, warping, or edge cracks to ensure smooth processing on high-speed production lines.

Related Articles

- Uses of different grades of aluminum closure sheets

- Which Aluminum Sheets Are Suitable for Wine Bottle Caps

- Aluminum foil lid for milk powder can sealing

- Aluminum bottle cap material 8011-h18 aluminum foil

- Aluminum closure sheet for cosmetic sealing 1070 1080

- Color coated aluminum foil for aluminum peel off end lid cap

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan