- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

ROPP Cap Raw Material - 3105 Painted Aluminum Sheet

Introduction

3105 aluminum sheet is an Al-Mn alloy (aluminum-manganese alloy) with excellent deep drawing performance, tensile strength, and corrosion resistance, making it an ideal choice for ROPP cap manufacturing.

With an aluminum content of about 98% and the addition of 0.3% copper, its electrical conductivity reaches 41%. In the annealed condition, 3105 aluminum has very high plasticity; in the half-hard condition, its plasticity remains good; while in the fully cold-worked condition, plasticity is reduced. It features good corrosion resistance and excellent weldability.

Production Process of Painted Aluminum Sheet

The production of 3105 painted aluminum sheet is a precise process. Plain aluminum coils undergo cleaning, chromizing, roller coating, and baking to achieve a surface coated with various colors of paint, forming the color coated aluminum coil.

The coating materials may vary depending on requirements, such as fluorocarbon resin (PVDF), polyester resin (PE), or epoxy coatings. These coatings ensure strong adhesion and excellent UV resistance, maintaining both appearance and stable performance during use.

For ROPP cap applications, high-quality food-grade coatings are generally used to guarantee safety and compliance with hygiene standards.

Advantages of Painted Aluminum Sheet for ROPP Caps

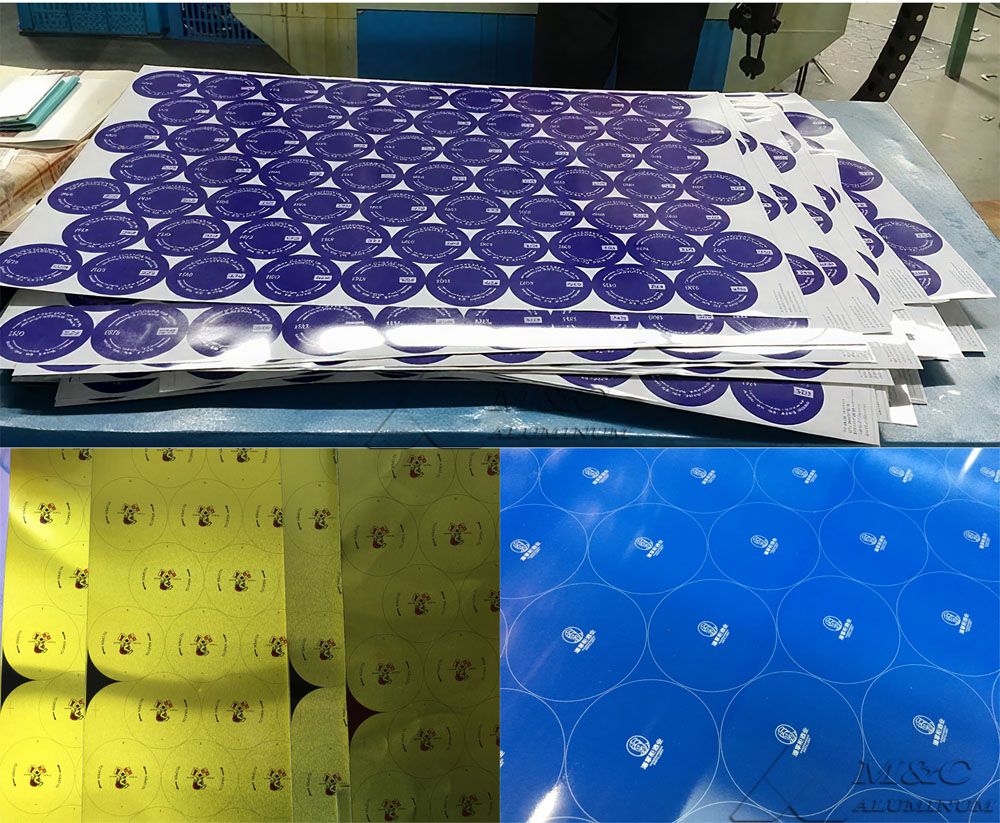

Brand Enhancement: Colors, patterns, and logos can be customized to serve as a “mobile advertisement.”

Anti-Counterfeiting: Unique printed designs are difficult to replicate, improving product security.

Substrate Protection: The coating effectively isolates air and moisture, extending the lifespan of bottle caps.

3105 ROPP Cap Aluminum Sheet - Product Information

Alloy Grade: 3105

Temper: H14, H16, H18

Thickness: 0.15 mm – 0.25 mm

Width: 200 mm – 1600 mm

Coil Inner Diameter: 505 mm / 610 mm

Coating Types: PE, PVDF, Epoxy

Coating Thickness: 5 – 20 μm

Surface Finishes: glossy, matte, brushed, mirror, anti-counterfeiting printing

Colors: silver, gold, red, blue, green, customized colors

Surface Quality: smooth, free from scratches, no color difference, no paint peeling

Packaging: wooden pallets / iron pallets, sealed with moisture-proof film

MOQ: 1 – 3 tons

Tempers and Dimensions of 3105 Painted Aluminum Sheet

Available Tempers:

O

H12

H14

H22

H24

H26

H28

Dimensions:

Thickness: the typical thickness for ROPP caps is 0.20 mm – 0.23 mm

Width: customized according to customers’ production equipment and cap size to maximize material utilization and minimize waste

Widths, lengths, and thicknesses vary depending on the hardness selected, and we can provide customized production according to customer requirements.

Surface Treatment Options for 3105 Aluminum Sheet

Glossy Surface: enhances visual impact, ideal for premium beverages and spirits packaging.

Matte Surface: understated elegance, commonly used for wine and pharmaceutical packaging.

Brushed / Mirror Effect: elevates texture, suitable for high-end cosmetics and functional drinks.

Anti-Counterfeiting Printing: digital printing or laser engraving creates unique identifiers on the cap surface to prevent counterfeiting.

Applications of 3105 Bottle Cap Aluminum Sheet

Wine and beverage bottle caps

Cosmetic bottle caps

Pharmaceutical packaging caps

Premium food packaging caps

Related Articles

- What kind of aluminum alloy is the aluminum alloy bottle cap

- 8011 3105 H14 H16 annealed aluminum sheet is suitable for bottle caps

- 3105 H14 H16 Anti-Theft Bottle Cap Aluminum Sheet

- Printed aluminum sheets for bottle caps

- Pilfer proof cap closure aluminum foil 8011

- Printed aluminum plate for screw caps 3105, 8011

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan