- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

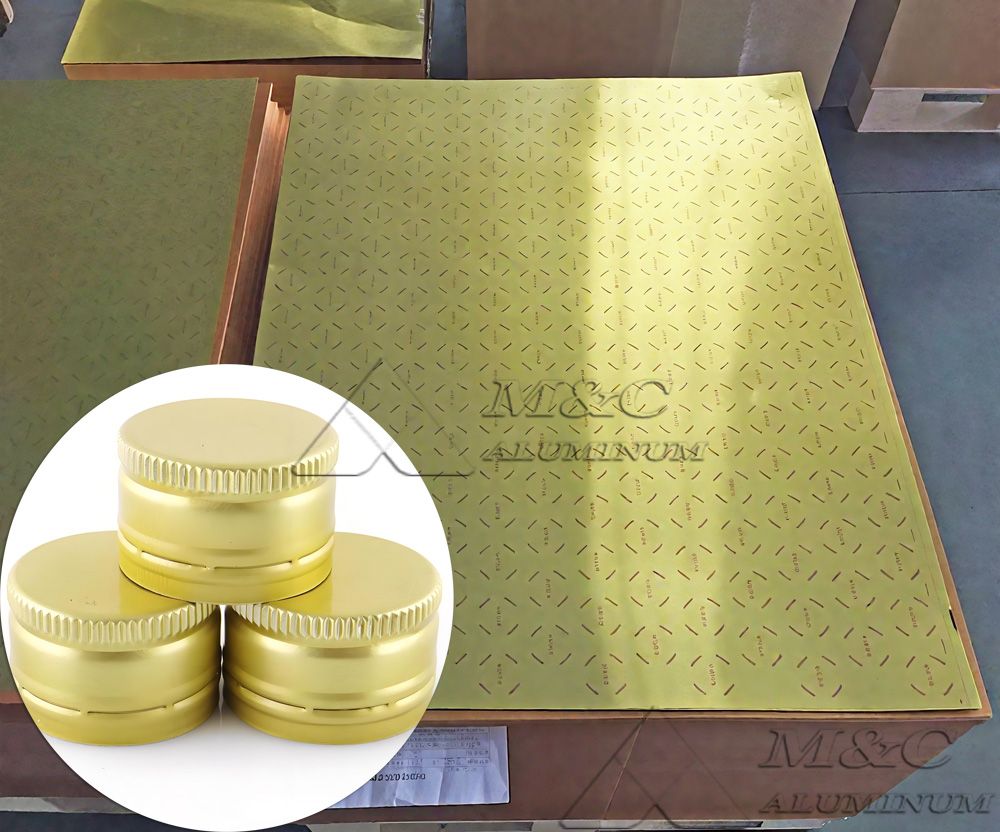

3105 H14 H16 Anti-Theft Bottle Cap Aluminum Sheet

Aluminum anti-theft bottle caps are made from food-grade aluminum alloy materials with precision processing. They are widely used for the sealing of alcoholic beverages, soft and carbonated drinks, as well as pharmaceutical and health supplement products, and can meet special requirements such as high-temperature steaming and sterilization.

Aluminum sheet and coil for anti-theft bottle caps can be classified by alloy grade into: 1100 bottle cap aluminum foil, 8011 bottle cap aluminum foil, 8011A bottle cap aluminum sheet, 3003 bottle cap aluminum sheet, 3105 bottle cap material, and 5052 bottle cap material. MC Aluminum uses hot-rolled billets for production to meet customers’ requirements for material strength, elongation, and dimensional accuracy, ensuring that the caps are easy to print after forming.

Compared with alloys such as 8011, 3105 aluminum sheet contains manganese (0.3%-0.8%) and magnesium (0.2%-0.8%), which significantly improves tensile strength (H14: 160-190 MPa; H16: 175-225 MPa). It can withstand the internal pressure of carbonated beverages and sparkling wines, preventing cap deformation or leakage.

3105 belongs to the anti-rust aluminum series, offering excellent corrosion resistance. Its surface can undergo chromating, painting, or film coating (such as single-sided gold or white). In H14/H16 tempers, it balances ductility and strength during deep drawing, reducing the risk of cracks or wrinkles during cap forming.

Temper States:

H14 (Quarter-Hard): This temper undergoes a certain degree of cold work hardening, offering moderate strength and hardness. It has excellent deep drawing performance and plasticity, suitable for bottle caps that require higher ductility for complex structures.

H16 (Half-Hard): This temper has a higher degree of hardening, providing greater strength and rigidity. It is ideal for cap designs that require stronger support and more durable structure.

Product Information

| Alloy | 3105 |

| Temper | H14, H16 |

| Thickness | 0.15-0.50mm (commonly 0.20-0.23mm ±0.01mm) |

| Width | 100-1600mm |

| Length | 100-6000mm |

| Surface Treatment | Mill finish, DOS oil lubrication, chromating, single-side color coating (gold/white/red, etc.) + protective back coating |

| Sample | Available |

| MOQ | 1-3 tons |

Mechanical Properties of 3105 Aluminum Closure Sheet

| Property | H14 | H16 |

| Tensile Strength (MPa) | 160-190 | 175-225 |

| Yield Strength (MPa) | 150 | 170 |

| Elongation (%) | ≥1 | ≥1 |

| Hardness (Brinell) | 48 | 56 |

Why Choose 3105 Aluminum Sheet for Anti-Theft Bottle Caps

1. Excellent Processing Performance: In H14 and H16 tempers, 3105 aluminum sheet offers excellent stamping and forming performance, suitable for deep drawing to produce finely detailed anti-theft cap structures.

2. Strong Corrosion Resistance: Ideal for food and beverage packaging, preventing external environmental effects and ensuring sealing integrity.

3. Good Mechanical Properties: Balanced hardness and strength ensure that caps remain secure during transport and use, with reliable tamper-resistance.

4. Safety: Non-toxic and odorless, safe and hygienic.

MC Aluminum is an experienced manufacturer of aluminum alloy bottle cap materials. Our base materials for bottle caps mainly include 1060 aluminum coil, 8011 aluminum foil, 1235 aluminum foil, 1070 aluminum foil, 1050 aluminum foil, 3105 aluminum sheet, and 3104 aluminum sheet. Our products are stable in quality, high in output, with short lead times, exported worldwide, competitively priced, and reliable for purchase.

Related Articles

- Painted aluminum alloy closure sheet 8011 3105

- Colored painted aluminum sheet for wine cap 8011 3105

- 8011 heat-sealed aluminum foil for easy-peel milk powder can lid

- china 3104 aluminum coil for the can and bottle cap material

- Vodka bottle aluminum cap material

- 5052 3104 H19 Aluminum closure sheet for can lid

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan