- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

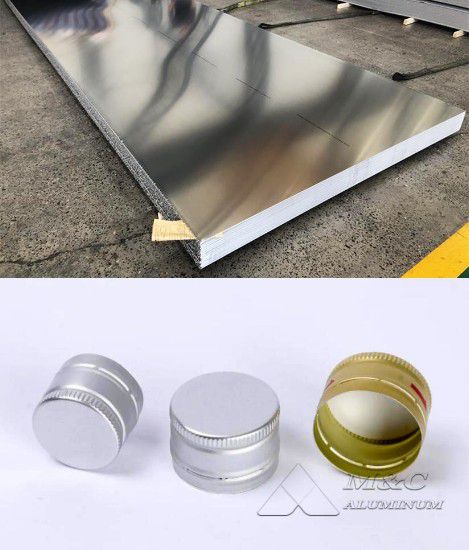

8011 anti-theft bottle cap aluminum sheet

Aluminum anti-theft bottle caps are mostly processed on production lines with a high degree of automation. Therefore, the requirements for the strength, elongation and dimensional deviation of the material are very strict, otherwise cracks or creases will appear during the processing. In order to ensure that the bottle cap is easy to print after it is formed, the surface of the bottle cap material is required to be smooth and free of roller marks, scratches, and stains. The production of aluminum bottle cap materials can be produced from hot-rolled billets, continuous casting and rolling billets, and cold-rolled billets. Generally, DC material 8011 H14 aluminum sheet is used.

8011 DC aluminum sheet for aluminum anti-theft bottle caps is suitable for packaging of beverages, wine, food, cosmetics, medicines, etc. Products are exported to more than 40 countries including the United States and Italy.

8011-H14 aluminum sheet product features:

1. Stable mechanical performance; Low ear rate, steady less than 2%, no ears for some products (Stable mechanical performance; Low ear rate, steady less than 2%, no ears for some products)

2. Good plasticity, capable of deep drawing of 75mm high bottle caps, without “orange peel” defects after stamping

3. The surface quality is better and fine lines are even.

4. High thickness accuracy, as low as ±0.005mm.

5. Grade A water brushing, low ear cutting rate

Specifications of 8011 aluminum sheet for anti-theft bottle caps:

| Temper | H14, H16 |

| Thickness | 0.15-0.25mm |

| Width | 20-1900mm |

| Type | Sheet |

| Surface treatment | double-sided transparent protective paint |

| Applications | Caps, closures and vials in the pharmaceutical industry. Anti-theft caps for the pharmaceutical industry. Caps and containers for the cosmetics industry. Wine bottle caps. |

| MOQ | 1-3 tons per size |

| Packaging | Export wooden box |

| Delivery time | 25-30 days after order and deposit |

| Price terms | EXW, FOB, CIF, CFR, CNF, etc. |

| Payment method | L/C, wire transfer, Western Union, etc. |

Chemical composition of 8011 aluminum plate for anti-theft bottle caps(%)

| Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al |

| 8011 | 0.60-1.0 | 0.50-0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | - | 0.08 | 0.15 | Remain |

Spectrum of 8011 Aluminium Sheet For Pilfer Proof Caps

| Mechanical Property for CC Materials of Aluminium Sheet for Bottle Cap | |||||

| Alloy | Temper | Thickness | U.T.S (Mpa) | Elongation (%) | Earring Rate |

| 8011 | H14 | 0.16-0.23 | 185-205 | ≥2 | <2% |

| Mechanical Property for DC Materials of Aluminium Sheet for Bottle Cap | |||||

| Alloy | Temper | Thickness | U.T.S (Mpa) | Elongation (%) | Earring Rate |

| 8011 | H14 | 0.16-0.23 | 125-155 | ≥2 | <2% |

Related Articles

- 8011 H14 Lacquer Aluminum Coil for Bottle Caps

- 8011 H14 hot rolled aluminum alloy bottle cap material

- Aluminum Alloy Bottle Cap Material Thickness

- Is 3105 Aluminum Sheet Cost-Effective for Bottle Caps?

- Bird's nest bowl with aluminum foil lid 8011

- 8011 Printed Aluminum Closure Sheets for Bottle Cap Manufacturing

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan