- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

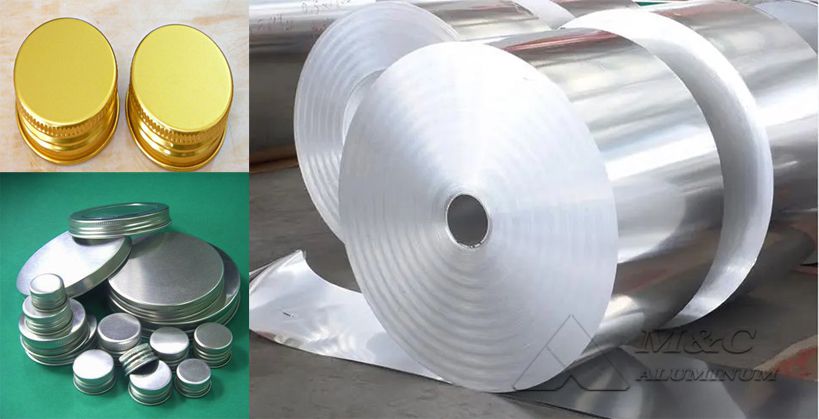

8011 H14 hot rolled aluminum alloy bottle cap material

The material thickness of aluminum bottle caps is generally 0.20-0.23 mm, and the width is 449-796 mm. Commonly used aluminum alloy numbers are 8011, 3003, 3105, and 5182, and their production processes include hot rolling, cold rolling, continuous casting, and continuous rolling. Among them, 8011 hot-rolled aluminum alloy is an important part of the anti-theft cover material.

The 8011 H14 aluminum alloy process needs to go through multiple processes such as cold rolling - foil rolling annealing thickness - annealing - foil rolling finished product - stretch bending and straightening - slitting. After the finished roll is produced, it must be cut by a flattening machine and painted. Multiple processes such as drying, multiple stampings, and anti-counterfeiting markings will produce qualified aluminum closure sheet materials throughout your life.

Specifications of 8011-H14 aluminum alloy for anti-theft bottle caps:

| Thickness | 0.15-0.27mm |

| Thickness tolerance | (+0.005mm) |

| Width | 330-1000mm |

| Width tolerance | (+1mm) |

| Length | can be customized |

| Surface treatment | coating |

| Tensile strength | 150-165Mpa |

| Elongation | >2% |

| Ear making rate | ≤2% |

| Application | bottle caps, medicinal aluminum caps, cosmetic bottle caps, yogurt caps, easy-open lids, aluminum sheet for can lids, etc. |

Advantages of 8011 H14 hot rolled aluminum alloy:

1. Excellent processing performance, suitable for various processing such as stamping, deep drawing, bending, cutting, etc., and can be processed into various shapes.

2. Good thermal conductivity, high and low temperature resistance, which can meet the special requirements of high-temperature sterilization and cooking of bottle caps

3. Light weight, high strength, not easy to deform during transportation

4. Good corrosion resistance, moisture-proof and light-shielding.

5. Beautiful and durable, with excellent printing performance.

The surface of 8011 hot-rolled aluminum alloy bottle cap material has no obvious roller marks, no obvious black lines, oil spots, dust inclusions, scratches, bright strips, etc. It is widely used in various wine bottles, beverage bottles, medicinal bottles and other packaging materials Bottle caps can meet the high-quality requirements of foreign bottle cap processing companies for this variety.

Related Articles

- 8011 3105 Coated aluminum sheet for aluminum cap

- 8011 Aluminum sheet for crown cap

- Why do bottle cap aluminum closure sheet need to be oiled?

- Price of 3105 aluminum coil for aluminum bottle cap

- Uses of different grades of aluminum closure sheets

- 3105 8011 printed aluminum plate for bottle cap anti-counterfeiting

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan