- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

8011 vs 3105: Which Alloy Is More Suitable for Aluminum Closures?

When it comes to aluminum closures, 8011 aluminum alloy often stands out due to its excellent formability, low earing rate, and flatness, making it an ideal choice for deep drawing processes, such as ROPP (Roll-On Pilfer-Proof) caps and small bottle seals. While 3105 aluminum alloy offers good strength and corrosion resistance, 8011 better meets the demanding requirements of closure manufacturing.

Overview of 8011 Aluminum Closure Sheet

8011 is part of the 8xxx series aluminum alloys, with iron (Fe) and silicon (Si) as its main alloying elements. These additions give 8011 unique softness and deep drawing performance, making it ideal for producing various complex foils and deep-drawn components, particularly ROPP caps. It's commonly used for wine and beverage bottle caps, as well as small vial seals. Tempers such as H14 and H16 are especially suitable for these applications.

Overview of 3105 Aluminum Closure Sheet

3105 belongs to the 3xxx series and primarily contains manganese (Mn), with small amounts of magnesium (Mg). The addition of manganese significantly improves the strength of pure aluminum, and magnesium further enhances its strength and corrosion resistance. It’s a versatile and cost-effective alloy. While it can be used for certain closure applications, it may not perform as well as 8011 in deep drawing and applications requiring low earing rates.

8011 vs 3105: Aluminum Closure Sheet Comparison

1. Chemical Composition

8011 Aluminum Alloy: Part of the 8xxx series (Al-Fe-Si alloy), containing approx. 1% Fe and 0.5% Si, with aluminum content ≥98%.

3105 Aluminum Alloy: Part of the 3xxx series (Al-Mn alloy), containing 0.3–0.8% Mn, 0.3% Cu, and 0.2–0.8% Mg, with aluminum content around 98%.

2.Alloy Characteristics

(1)8011 Aluminum Closure Foil

High Ductility: In annealed (O) temper, elongation can exceed 20%, suitable for complex deep-drawing (e.g., yogurt lids, pharmaceutical bottle caps).

Food-Grade Safety: Clean, non-toxic surface, compliant with health standards for food and pharmaceutical packaging.

Lower Cost: Mature production process, more affordable than other alloys.

(3)3105 Aluminum Closure Sheet

Higher Strength: Cold-worked tensile strength can reach 270–350 MPa, ideal for closures requiring compressive or dynamic load resistance (e.g., carbonated beverage caps).

Excellent Conductivity: Due to copper content, electrical conductivity can reach 41%, suitable for closures with conductive requirements (e.g., electronics packaging).

Corrosion Resistance: Enhanced by manganese, though long-term exposure to acidic liquids may reduce performance.

3. Cost & Processing Efficiency

From a cost perspective, 8011 is typically produced via Continuous Casting (CC), allowing high output and low cost, making it very price-competitive. In contrast, 3105 is often produced via Direct Chill (DC) hot rolling, which offers better mechanical properties but at a higher cost. For large-scale, cost-sensitive production, 8011 is more attractive.

In terms of processing, 8011 demonstrates more stable performance in stamping, forming, and printing, resulting in higher yields.

4. Application Scenarios

8011 aluminum foil is ideal for tamper-evident caps, pharmaceutical bottle caps, and other precision stamping applications requiring deep forming and low earing.

3105 aluminum sheet is suitable for high-end caps, acidic liquid closures, and applications requiring welding, such as carbonated beverage caps.

5. Environmental and Sustainability Aspects

Both alloys are highly recyclable. However, 8011 has broader applications and a well-established recycling system, making it a more sustainable option for building green supply chains.

Conclusion

Both 8011 and 3105 are excellent alloys for manufacturing aluminum closures, each with its own strengths. 8011 excels in complex shapes and high-precision closures due to its superior deep-drawing performance and low earing rate. 3105, with its higher strength and cost-effectiveness, performs well in general-purpose and rigidity-demanding closure applications.

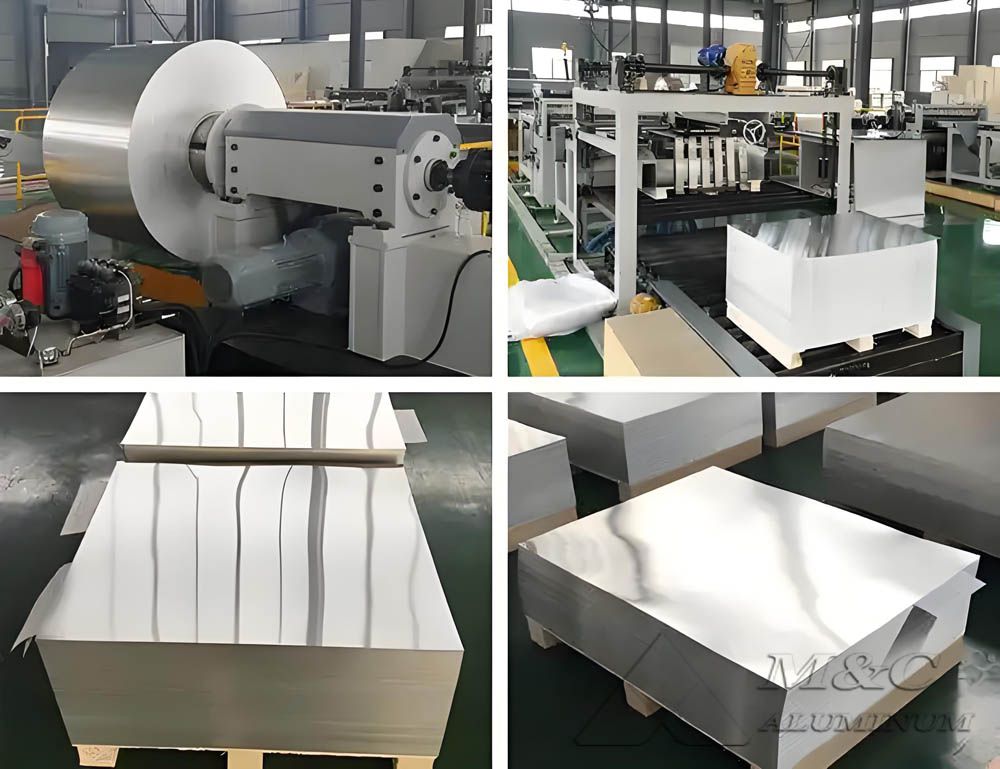

MC Aluminum is a professional supplier of aluminum closure coils, offering complete solutions for all types of cap applications, such as aluminum screw caps, ROPP caps, small vial closure, Omnia caps, twist-off caps, EOE ends, and cosmetic packaging. We provide various grades of aluminum closure sheets, including 8011 foil, 3105 aluminum closure sheet, 5052 alloy, 1070 strip, and 5182 alloy, with stable quality, export capability, free samples, and short lead times.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan