- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

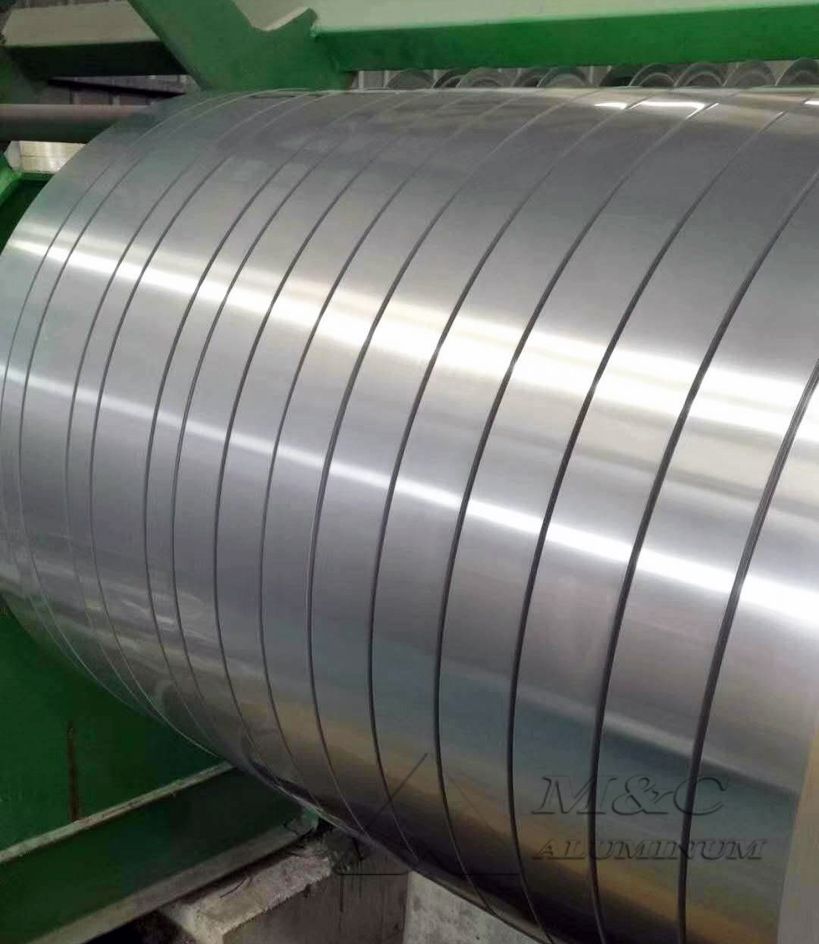

8011 H16 anti-theft cover aluminum alloy strip

With the continuous improvement of domestic water products, the consumption of various beverages and alcohol is increasing year by year. Aluminum anti-theft bottle caps are an important material because of their simple and beautiful appearance, smooth surface, low cost, no pollution, and recyclability. , good deep drawing performance, anti-theft opening and other advantages, it is widely used in mass production.

Aluminum alloy bottle cap materials usually use 8011 H16 aluminum strip. After being baked in the cap making process, it has certain strength advantages, good sealing performance, corrosion resistance, excellent aesthetics, and excellent processing performance. The anti-theft cover aluminum closure sheet is widely used for packaging alcohol, beverages (steamed and non-steamed), oral liquids, and pharmaceutical and health care products, and can meet special requirements such as high-temperature cooking and sterilization.

8011 H16 aluminum alloy strip specifications:

| Thickness | 0.16-0.30mm |

| Thickness tolerance | ±0.005mm |

| Width | 441-1600mm |

| Width tolerance | ±0.5mm |

| Tensile strength | 149-165MPa (tensile strength after baking: ≥139MPa) |

| Elongation | ≥2% |

| Ear making rate | ≤2% |

Anti-theft cover aluminum alloy strip product features:

1. Stable mechanical properties; low ear rate, stable below 2%, and some products have no ears.

2. Good plasticity, can be deep-drawn for 75mm high covers, and there will be no "orange peel" defects after stamping.

3. Better surface quality and uniform fine lines.

4. High thickness accuracy, as low as ±0.005mm.

5. Superior performance, good extension effect, good processing performance, easy to print, and exquisite patterns

6. It has good sealing performance and can meet special requirements such as high-temperature cooking and sterilization.

7. High recycling rate and good environmental protection effect.

MC Aluminum is a professional manufacturer of aluminum bottle cap materials. The 8011 H16 aluminum alloy strip produced for bottle caps has high dimensional accuracy, small sheet flatness, smooth surface, low ear rate, and is durable after baking. It has good strength and neat roll end without burrs.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan