- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

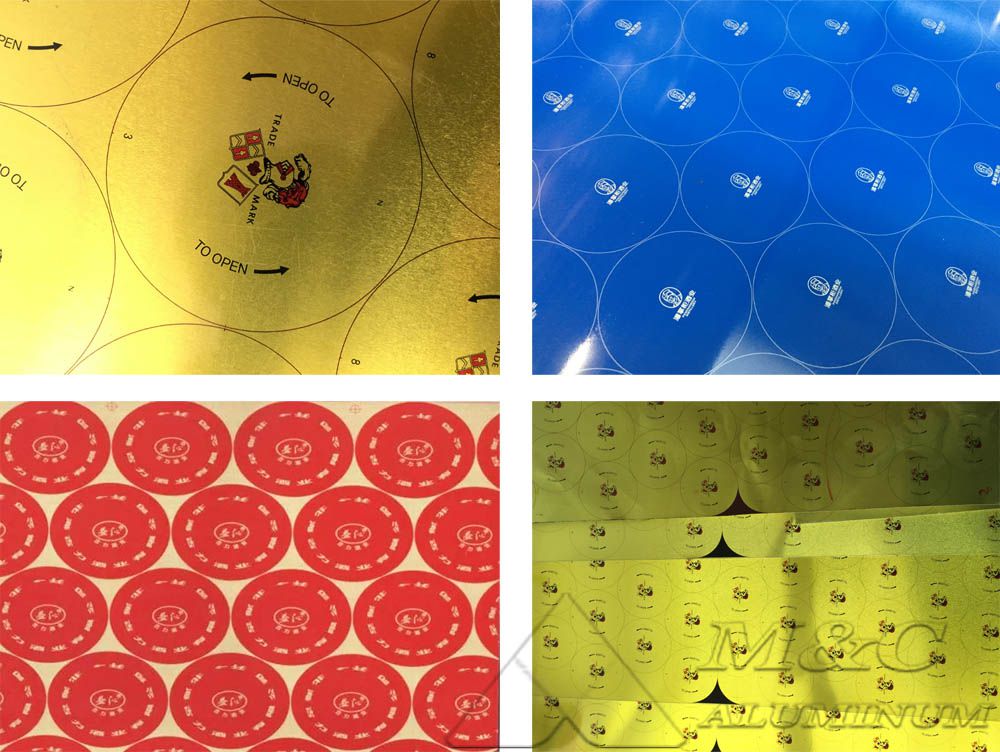

Aluminum Anti-Theft Bottle Cap Material

Aluminum anti-theft bottle cap material is a key material in the modern packaging industry. With advantages such as lightweight, high sealing performance, and recyclability, it is widely used in the packaging of alcoholic beverages, soft drinks, pharmaceuticals, and cosmetics. The main alloys used are 8011-H14/H16 and 3105-H16, which provide a balance of high strength and ductility to meet the demands of stamping, forming, and printing.

Core Advantages of Aluminum Anti-Theft Cap Material:

High Strength and Toughness: Aluminum material provides excellent tensile and impact resistance, ensuring the cap withstands sealing pressure while adapting to varying bottle neck sizes.

Excellent Processability: Easy to stamp, stretch, and form—ideal for automated production lines with high precision and surface quality requirements.

Corrosion Resistance: A dense oxide film naturally forms on the surface, effectively resisting moisture, acids, and alkalis, extending the shelf life of the cap.

Eco-Friendly and Recyclable: Aluminum can be infinitely recycled, aligning with global trends in sustainable and green packaging.

Aluminum Alloy Bottle Cap Material Specifications:

| Alloys | 8011, 3105, etc. |

| Temper | O, H14, H16, H18, etc. |

| Thickness | 0.15–0.27 mm |

| Width | 200–1000 mm (customizable) |

| Length | 100–6000 mm |

| Core ID | 76 mm / 150 mm |

| Type | Sheet / Coil / Strip |

| Surface Treatment | Mill finish, coated, anodized, printed |

| Surface Colors | Silver, gold, blue, red, etc. (printable) |

| Coating Type | Single-side, double-side, epoxy/PE coating |

| Coating Thickness | 4–6 μm (single side) |

| Applications | Threaded caps, PP bottle caps for carbonated drinks, beverage cans |

| Packaging | Moisture-proof packaging, wooden pallets |

| MOQ | 1–3 tons |

Typical Applications:

Alcohol Bottle Caps: Anti-theft aluminum caps for liquor, red wine, and grape wine

Beverage Bottle Caps: Tamper-evident caps for carbonated drinks, juices, and teas

Pharmaceutical Caps: Aluminum caps for oral liquid vials and ampoules

Cosmetic Packaging: Bottle caps for essential oils and small-volume cosmetic bottles

Other Special Uses: Sealing materials for nutritional products and daily chemicals

Why Choose MC Aluminum?

1.Aluminum sealing sheets are produced with clean, flat surfaces free from scratches, oxidation spots, and oil stains.

2.Coil ends are even, free of burrs and deformation.

3.Coatings are uniform with adhesion levels meeting national or customer-specific standards.

4.Compliance with environmental and food-grade standards such as RoHS, REACH, and FDA (on request).

Related Articles

- 1060 3105 5052 8011 Aluminum Closure Sheet for Bottle Caps

- 3105 DD / DC Aluminum Sheet Coil for Closure Applications

- Anti-theft wine lid 8011 aluminum foil

- Aluminum closure cap production process

- Aluminum foil substrate for beverage bottle caps 8011 H16 H18

- Standards for aluminum plates for bottle caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan