- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

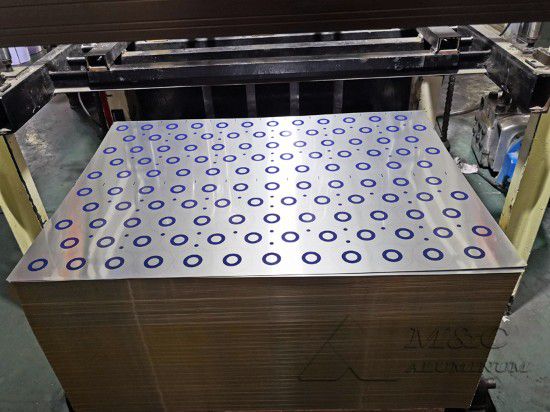

Aluminum bottle cap production process

In recent years, aluminum alloy bottle caps have been increasingly used in people's daily lives, especially in the packaging of alcohol, beverages, and medicines.

Aluminum bottle caps have simple shapes and fine production. Advanced printing technology can achieve consistent colors and exquisite patterns, giving consumers an elegant visual experience. In addition, aluminum bottle caps have good sealing performance, excellent performance and More and more applications.

Aluminum bottle caps are mostly processed on production lines with a high degree of automation, so the requirements for material strength, elongation, dimensional deviation, etc. are very strict, otherwise breaks or creases will occur during the processing.

Generally, the alloys used for aluminum alloy bottle cap materials include 8011 alloy, 3003 alloy and 3004 alloy. 1050 and 1060 alloys are also used. Which alloy aluminum sheet is selected according to the stretch length of different products.

Material requirements: The bottle cap material sheet should be straight and free of rolling marks, scratches and stains.

Common alloy states: 8011-H14, 3003-H16, etc.

Material specifications: general thickness 0.20mm-0.23mm, width 449mm-796mm.

Production process: Aluminum bottle cap materials are supplied by hot rolling or continuous casting and rolling, and then cold rolled. Domestic manufacturers that produce anti-theft cover materials mostly use continuous casting and rolling billets, whose performance is better than that of cast and rolled billets.

Due to the continuous innovation of technology, the functions and production forms of aluminum bottle caps are also developing in a diversified and personalized direction. Aluminum bottle caps are not only mechanized and large-scale, but also low-cost, pollution-free, and can be recycled. Therefore, in future wine bottle caps, we may foresee that aluminum bottle caps will still be the mainstream.

MC Aluminum is a professional aluminum bottle cap material manufacturer, providing 8011 aluminum foil, 3105 aluminum closure sheet, 3003 aluminum sheet and other products, which meet the strict requirements of bottle cap materials. The surface of the bottle cap material should be smooth and free of roll marks, scratches and stain.

Related Articles

- Painted aluminum alloy closure sheet 8011 3105

- Aluminum closures for bottle cap sealing

- How to choose aluminum bottle cap material?

- Printed 8011 3105 aluminum sheet for PP bottle caps

- 8011 heat-sealed aluminum foil for easy-peel milk powder can lid

- Price of 3105 aluminum coil for aluminum bottle cap

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan