- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

How to choose aluminum bottle cap material?

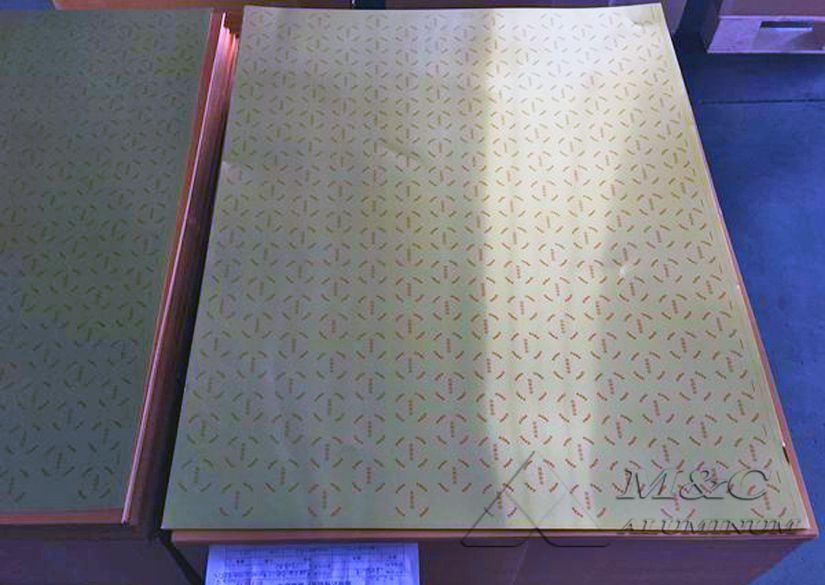

In daily life, aluminum bottle caps can be seen everywhere and are used more and more widely. Aluminum alloy bottle cap materials are mainly used in packaging of alcohol, food and beverages, cosmetics, etc. Aluminum bottle cap materials mainly use 1xxx, 3xxx, and 8xxx series aluminum alloy sheets to meet the strict requirements of bottle cap materials. The product surface is smooth and free of rolling marks, scratches and stains.

The production of bottle caps requires very high product quality, so it is inevitable for the industry to choose high-quality manufacturers to purchase high-quality bottle cap materials. There are many manufacturers of bottle cap materials on the market, and customers are easily confused during the selection process. So how to choose aluminum bottle cap materials, I will analyze them according to their own situation.

1. Manufacturer’s strength

The strength of the manufacturer can be related to the manufacturer's development direction, investment technology, financial strength and management direction planning. Its ultimate goal is to improve equipment quality and after-sales service, as well as stabilize product prices. Otherwise, the manufacturer's strength is average and the product Quality, price, and after-sales service cannot be guaranteed. It is recommended that users choose a stronger aluminum foil manufacturer.

2. The technological level of aluminum bottle cap materials

Since the use of aluminum bottle cap materials is relatively special, the requirements for processing technology are particularly high. MC Aluminum adopts the internationally advanced "1+4" hot rolling production line, so that the advanced process quality is more guaranteed. It meets the various processing requirements of customers and is suitable for multi-color printing. The products are widely used in various purposes and are safe and high-quality.

3. Product quality of aluminum bottle cap materials

Aluminum bottle cap material product testing is a very important step. Customers must inspect the supplier's products in detail. For example, the superior quality of MC Aluminum's aluminum bottle cap material ensures that the product has a flat shape, precise geometric dimensions, and high surface gloss. The alkali cleaning effect is good and can reach level A in the water brushing test. The end surface of the aluminum strip is smooth and has no defects such as parabolic lines and collapse lines.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan