- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

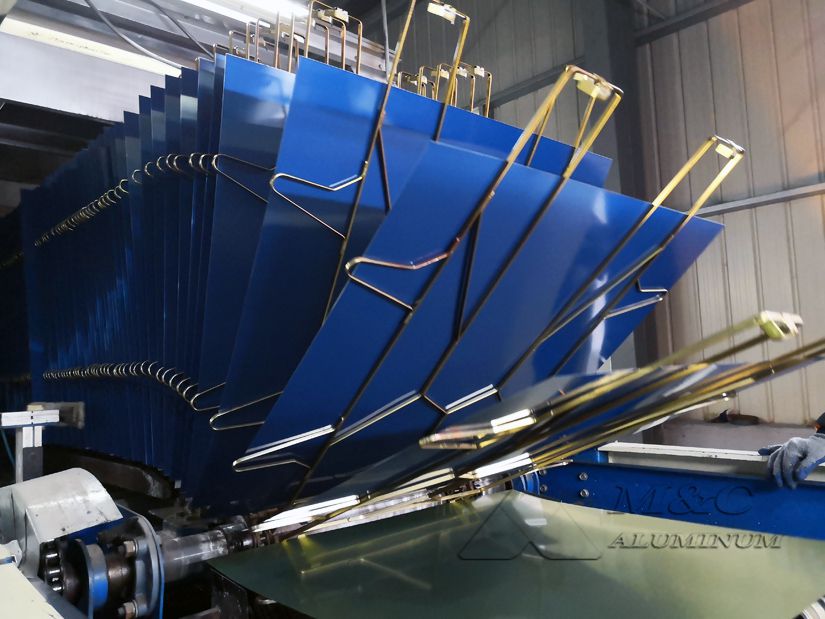

Different alloy bottle cap aluminum sheets

Aluminum alloy bottle cap material is a new type of environmentally friendly bottle cap sealing material. It is not only beautiful and easy to open, but also has anti-counterfeiting functions. The aluminum cap is also easy to process and recycle, which is energy-saving and environmentally friendly. Therefore, it is widely used in the sealed packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc.

When processing aluminum bottle caps, the requirements for material strength, elongation and dimensional deviation are very strict, otherwise cracks or creases will occur. In order to ensure that the bottle cap is easy to print after it is formed, the surface of the bottle cap material should be smooth and free of rolling marks, scratches and stains. Aluminum sheets for bottle caps mainly include 1xxx, 3xxx, and 8xxx aluminum alloys, including 1060 aluminum sheets, 3105 aluminum sheets, 8011 aluminum sheets, etc.

8011 aluminum sheet has good deep drawing performance, low lug rate, and has a certain strength after work hardening. It has the advantages of light weight, good barrier properties, and good processing performance. It is usually used to make aluminum ROPP covers, aluminum PP covers, anti-theft covers, aluminum screw covers, easy-tear covers, etc.

3105 aluminum sheet is an ideal material for bottle cap production and is very suitable for making bottle caps for wine bottles, beverage bottles, soft drinks, juices, energy drinks and high-end cosmetics. 3105 aluminum sheet has the characteristics of high strength and can withstand greater gas pressure, and is widely used to make gas-filled beverage bottle caps. After being treated with chromium phosphate or DOS coating, the 3105 bottle cap aluminum sheet can be printed in different colors and decorated with different styles of wine bottle caps and other bottle caps.

1060 bottle cap aluminum sheet has high elongation, tensile strength, excellent electrical conductivity, high formability, and meets processing (stamping, stretching) requirements. 1060 aluminum sheet can be combined with plastic to make aluminum-plastic bottle caps, which are widely used in the pharmaceutical industry, cosmetics industry, etc., and can meet the special requirements of high-temperature cooking and sterilization.

| Bottle cap aluminum plate specifications | |||

| Alloy | 1060 | 3105 | 8011 |

| Temper | O,H22,H24 | H14,H24,H16,H26,H18 | H14,H24,H16,H26,H18 |

| Thickness | 0.15-0.5mm | ||

| Width | 100-2650mm | ||

| Rolling Process | CC/DC | ||

| Surface Treatment |

| ||

| Delivery time | 25-30 days | ||

| Package | Export package | ||

MC Aluminum is a professional aluminum alloy bottle cap material manufacturer. The ends of the product should be neat and free of cracks, burrs, warping, flanging, burrs, unevenness, etc. It is a raw material supplier for domestic and foreign bottle cap material manufacturers. Exported to the United States, Germany, South Korea, Japan, and Southeast Asian countries.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan