- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

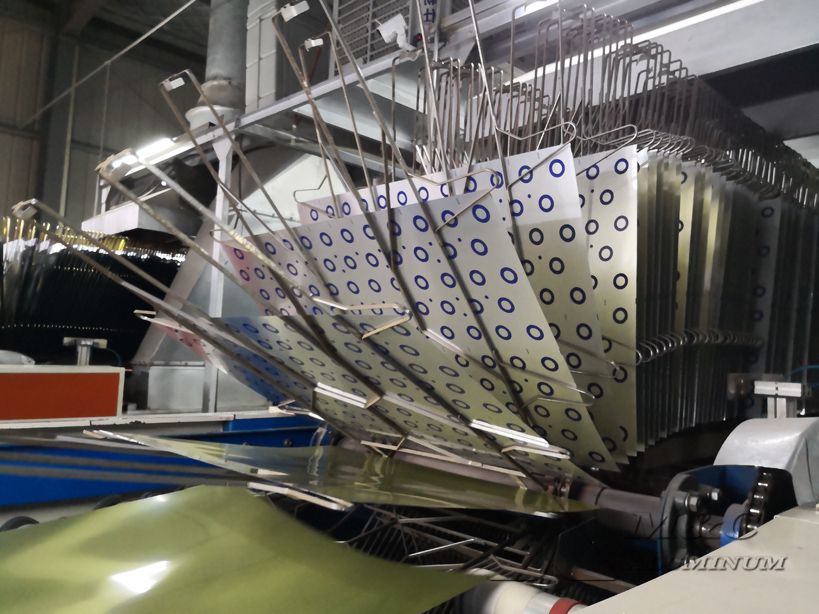

Aluminum foil roll raw materials for bottle caps

The aluminum alloy bottle cap materials produced by MC Aluminum include 1100 aluminum coil, 8011 aluminum foil, 3003 aluminum coil, 3105 bottle cap material, 5052 aluminum coil, etc. The bottle cap materials are all hard, with a hardness between H14-H24. The elongation strength is between 110-320, and the elongation rate is generally not less than 4. It is mainly used in bottle cap packaging and other fields such as alcohol, beverages, cosmetics, medicine, etc.

Introduction to aluminum foil rolls for bottle caps:

3105/3003 aluminum coil for wine bottle caps: good deep drawing processing performance, certain tensile strength and yield strength, low ear rate, and easy processing;

8011 aluminum coil for pharmaceutical packaging grade bottle caps: Aluminum caps made of 8011 aluminum foil are thin and easy to open, and are widely used in pharmaceutical oral liquids.

5052 aluminum coil for can lid material: 5052 aluminum coil has good corrosion resistance, weldability, cold workability, medium strength, and its surface is bright after coating.

Aluminum foil roll specifications for bottle caps:

| Alloy | 1060,1235,3003,3104,3105,5052,8011,etc |

| Temper | H14, H16, H18, H19 |

| Thickness | 0.012-0.5mm |

| Width | 100-1600mm |

| Length | 100-16000mm (can be customized) |

MC Aluminum is a manufacturer of aluminum foil roll raw materials for aluminum bottle caps. The company's 8011 aluminum foil, 3105 aluminum foil, etc. are the source of aluminum foil raw materials for various aluminum bottle cap factories at home and abroad. MC Aluminum's aluminum alloy bottle cap material has a flat surface, no rolling marks, scratches and stains, and has excellent performance.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan