- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Aluminum alloy for beer crown cap

The crown cap originated in 1892, invented by American William Painter, and is still the mainstream sealing method for bottled beer today. Traditional crown caps are mainly made from tin-plated steel (tinplate) or galvanized steel. However, with the growing demand for lightweight, environmentally friendly, and recyclable materials, aluminum alloy has gradually become a better choice.

The most commonly used aluminum alloys for beer aluminum sealing caps are 3105, 5052, and 8011. These materials offer excellent corrosion resistance, formability, and sealing performance.

Introduction to Common Aluminum Alloys for Sealing Caps

8011 Aluminum Alloy:

The main components of 8011 aluminum alloy are Al+Fe+Si. The addition of iron and silicon forms a dense oxide layer, enhancing corrosion resistance and sealing performance. 8011 aluminum sealing caps are typically in H14/H16 temper, hardened through processing to achieve high strength while maintaining plasticity, making them suitable for stamping.

3105 Aluminum Alloy (Mainstream Material for Crown Caps):

Composition: Aluminum (Al) content above 98%, with small amounts of manganese (Mn) and magnesium (Mg).

Features: Moderate strength, excellent corrosion resistance, suitable for stamping, widely used in bottle cap manufacturing.

5052 Aluminum Alloy (High-Strength Crown Caps):

Composition: Magnesium (Mg) content 2.2%-2.8%, which enhances strength and toughness.

Features: High tensile strength, excellent weather resistance and oxidation resistance, suitable for high-end beer brands.

Advantages of Aluminum Alloy for Beer Sealing Caps:

Lightweight: Aluminum alloy is 30% lighter than steel, reducing production and transportation costs, and improving logistics efficiency.

Corrosion Resistance: The natural oxide film on aluminum alloy prevents rust, making it ideal for long-term storage and transportation of beer.

Eco-Friendly: Aluminum alloy is 100% recyclable, in line with the trends of "carbon neutrality" and "green packaging," saving 95% of recycling energy.

Good Sealing Performance: 8011 aluminum alloy liner helps prevent CO2 leakage, preserving beer flavor and bubble fullness.

Excellent Processing Performance: Aluminum alloy is suitable for large-scale production, improving manufacturing efficiency and reducing waste.

Application Scenarios:

Aluminum bottle caps are widely used in the packaging of beer, beverages, cosmetics, and pharmaceuticals due to their attractive appearance, ease of opening, and anti-counterfeiting features.

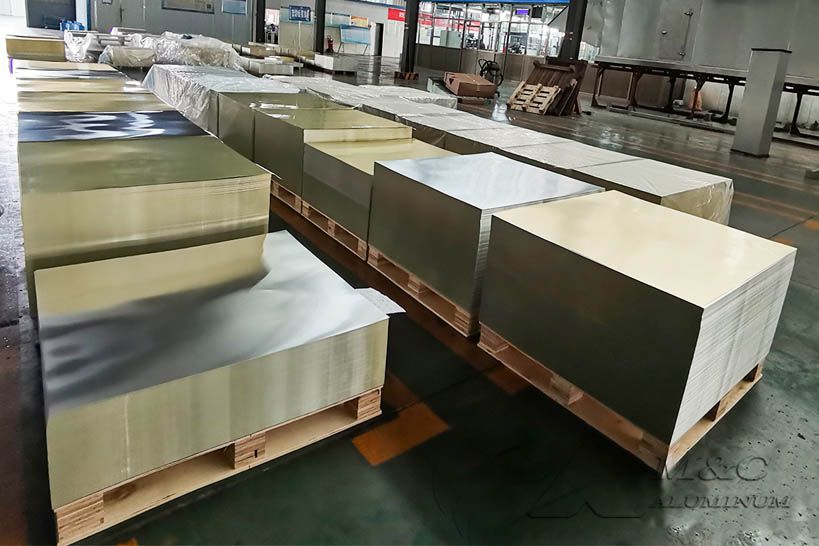

MC Aluminum is a professional manufacturer of aluminum bottle cap materials, specializing in the production of 3105 aluminum sealing sheets, 5052 aluminum alloy, and 8011 aluminum foil for beer caps. Our products are flat, with clean surface oil removal, no black streaks, no printing marks, and burr-free edges. Our products are sold overseas and are highly praised by customers. We offer direct sales with competitive prices and samples upon request.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan