- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

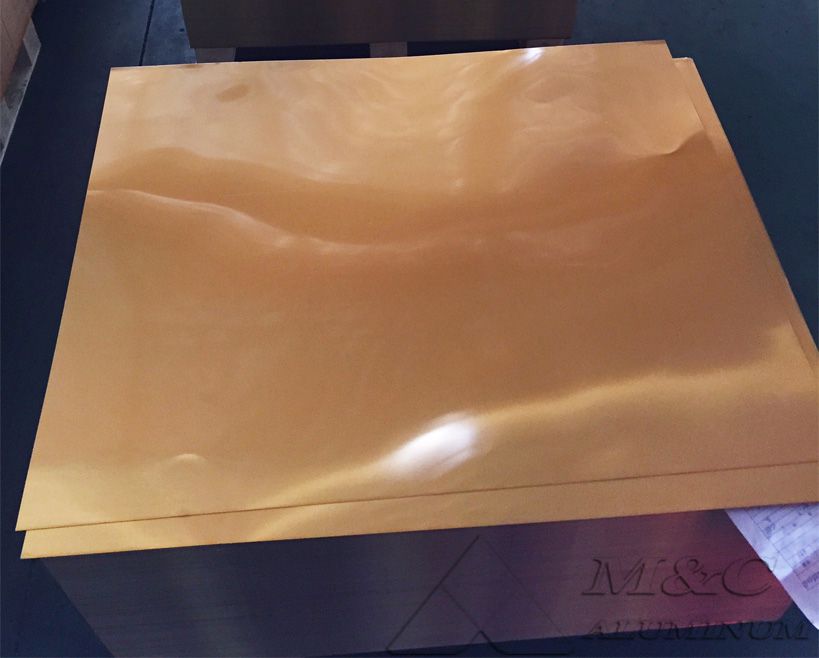

Aluminum substrate for bottle caps

Aluminum substrate for bottle caps is a key material in the packaging field. Aluminum is easy to make various bottle caps through stamping, stretching and other processes due to its excellent ductility, and it is not easy to break during the molding process. Its good corrosion resistance can keep the bottle caps stable in complex environments and ensure the safety of the contents. In addition, the lightweight characteristics of aluminum reduce transportation costs and bring convenience to consumers, so it is widely used in bottle cap manufacturing.

According to the specific use and performance requirements of the bottle caps, choose the appropriate aluminum alloy sheet material. MC Aluminum develops and produces various types of aluminum bottle caps, such as 1060 aluminum sheet, 3104 aluminum sheet, 5052 aluminum sheet, 8011 aluminum foil, etc. These aluminum alloy sheets have different characteristics, such as strength, corrosion resistance, plasticity, etc., to meet the requirements of different products for bottle caps.

Aluminum base alloy number for bottle caps

1 series aluminum alloy

1060 aluminum sheet: The aluminum content can reach 99.6%, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. It has good elongation and tensile strength, can meet conventional processing requirements, such as stamping and stretching, and has high formability. It is usually used as aluminum cap raw material.

3 series aluminum alloy

3104 aluminum sheet: The tensile strength is greater than or equal to 275MPA, the elongation can reach 20%, and it has good deep drawing performance. It is suitable for thinning and stretching to reduce material consumption. It is suitable for making beverage can caps, etc. .

3105 aluminum sheet: Especially suitable for bottle caps of alcoholic products.

5 series aluminum alloy

5052 aluminum sheet: Suitable for making pull-top type bottle caps, with certain strength and corrosion resistance, and shows good forming performance during processing.

8 series aluminum alloy

8011 aluminum foil: It is one of the commonly used aluminum alloys for bottle caps, with stable physical properties, easy stamping and high strength. The surface texture is fine and there is no black silk or black line, and the tensile strength is greater than 165MPA. It has good sealing, corrosion resistance and safety, and is widely used in the manufacture of wine bottle caps, beverage caps, milk powder caps, dry goods easy-pull caps and medical bottle caps, such as oral liquid bottle caps, capsule aluminum foil sheets, etc.

Classification of aluminum alloy bottle cap materials:

1.Anti-theft cap materials: Commonly used in carbonated beverages and mineral water bottle caps.

2.Medical bottle cap materials: Aluminum caps used for injections, infusions and other medical products.

3.Easy-pull cap materials: Commonly used in beer and beverage can caps.

Quality requirements of bottle cap materials for aluminum substrates:

1. Surface quality: No obvious scratches, dents, oil stains, oxidation and other defects, low surface roughness, to ensure good adhesion of printing and coating, and improve the appearance quality and protective performance of bottle caps.

2. Dimensional accuracy: The thickness tolerance is extremely small, for example, it is controlled within ±0.05mm to ensure that the thickness of the bottle cap is uniform after stamping; the length and width dimensions are accurate to ensure that the shape of the punched bottle cap is regular and meets the requirements of the mold design.

3. Chemical composition: The alloy element ratio is accurate to ensure uniform material performance. For example, the ratio of each element in a specific aluminum alloy meets the standard range to avoid the impact of composition fluctuations on processing and use performance.

4. Corrosion resistance requirements: It can resist the erosion of common media, such as not rusting or deteriorating for a long time in weak acid, weak alkali or humid environment, and meet the safety standards for food and drug packaging contact materials to prevent the contents from being contaminated.

5. Mechanical properties: It has appropriate strength, and the tensile strength meets the corresponding standards, such as 100-200MPa. At the same time, it has sufficient ductility, and the elongation is not less than 20%, which is convenient for stamping complex-shaped bottle caps without cracking.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan