- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Vodka bottle aluminum cap material

The aluminum closure caps for vodka bottles are mainly made of aluminum. This type of aluminum closure cap usually has good sealing and corrosion resistance, which can ensure the quality and safety of vodka during storage and transportation. In the design of some high-end vodka bottles, aluminum closure caps may also be combined with other materials or processes, such as metal nameplates or hazy frosting processes, to enhance the overall texture and grade of the bottle. In short, aluminum is a commonly used material for vodka bottle closure caps.

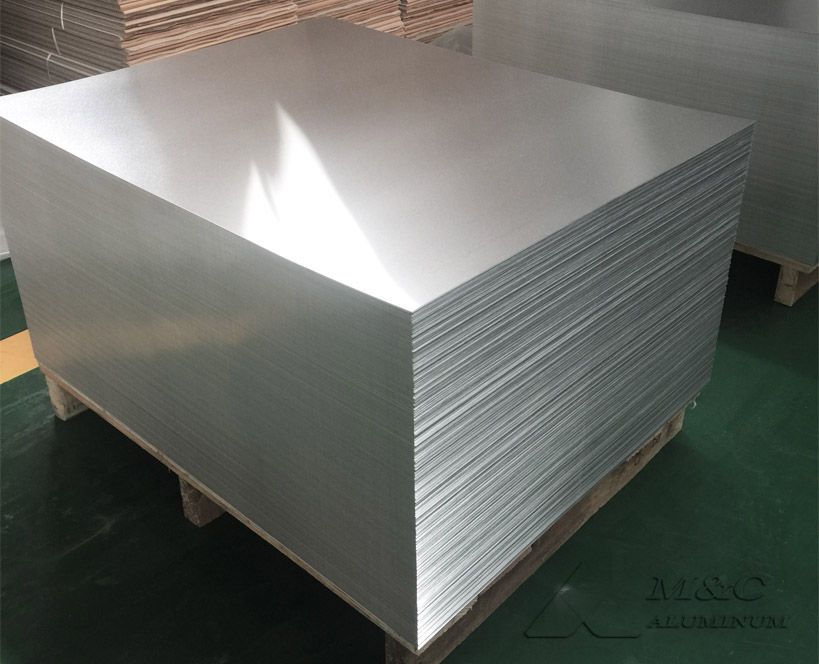

The types of aluminum alloys commonly used for vodka bottle aluminum closure caps mainly include 1060 aluminum sheet, 3003-H16, 8011-H14 and other alloys. These aluminum alloy materials are widely used in the manufacture of aluminum closure caps for vodka bottles due to their good processing performance, sealing and corrosion resistance. Among them, 8011 aluminum foil is also particularly favored for its stable physical properties, easy stamping, high strength, fine surface texture without black silk and black lines, and is widely used in the manufacture of beverage caps such as wine bottle caps. The selection of these alloys is intended to ensure the sealing, safety and overall quality of vodka bottles.

Features of aluminum closure sheets for wine bottle caps:

1. Lightweight: Aluminum is light in weight and easy to transport and use.

2. Corrosion resistance: The oxide film formed on the surface of aluminum alloy can prevent oxidation and corrosion, ensuring the quality of the wine.

3. Sealing: Aluminum has good toughness and is easy to process into a threaded shape, and can be matched with a built-in sealing gasket to ensure a sealed effect.

4. Impact resistance: It has a certain hardness and toughness, which can prevent damage during transportation and use.

5. Anti-counterfeiting design: Some aluminum closure caps are added with laser engraving, invisible marking and other technologies to improve anti-counterfeiting performance.

6. Easy to open: Through spiral design or other opening methods, it is convenient for consumers to use.

7. Environmentally friendly and recyclable: Due to its material characteristics, the aluminum closure sheet can be completely recycled and reused, which is in line with the modern environmental protection trend.

Quality inspection requirements for aluminum closure sheets for wine bottle caps produced by MC Aluminum:

1. Appearance inspection: uniform color, full molding, smooth surface, and no obvious defects (such as shrinkage, burrs, gaps, etc.).

2. Sealing performance inspection: Ensure that the aluminum closure sheet has good sealing performance and no leakage under a certain pressure after closing the cap.

3. Strength performance inspection: The aluminum closure sheet must have a certain strength and be able to withstand the natural fall of a 500ml water bottle without damage.

4. Corrosion resistance inspection: The aluminum closure sheet should be corrosion-resistant to ensure that no chemical reaction or deterioration occurs when in contact with alcohol for a long time.

5. Other inspection items: may include anti-theft, torque, tension, torque, paint film wear, unscrewing force, pressure resistance, wear resistance, opening force and other inspections.

Related Articles

- Medical aluminum-plastic cap manufacturer

- Deep drawn bottle cap material aluminum alloy strip 8011 3105

- 3105 Aluminum Closure Sheet for Beverage Container Caps

- Colored Coated Aluminum Sheet for Beverage Caps

- Hot-Rolled 3105 Aluminum Sheet for Bottle Caps

- 25mm Anti-theft aluminum bottle cap material supply

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan