- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

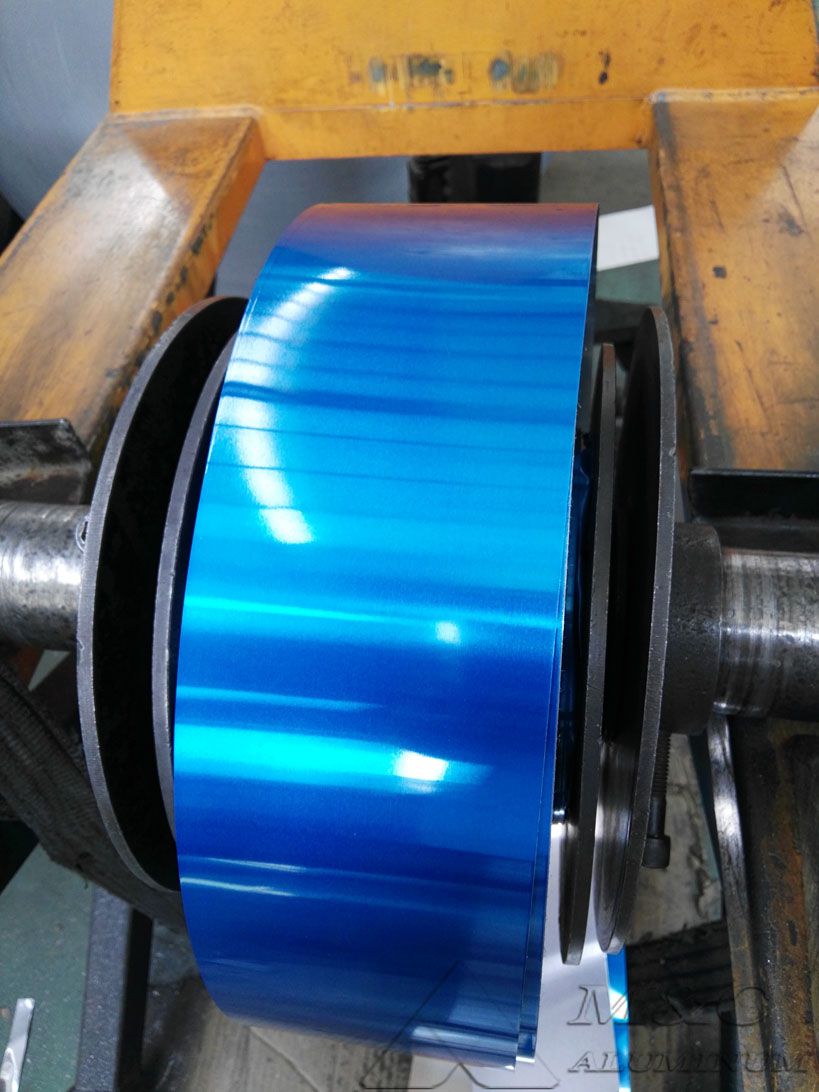

Color coated bottle cap material aluminum strip

Coated bottle cap material aluminum strip usually refers to aluminum strip that has been surface treated and coated with a specific coating, which is used to make sealing materials for various bottle caps, such as beverage bottle caps, wine bottle caps, cosmetic bottle caps and medicine bottle caps. These bottle caps not only have a beautiful appearance, but are also easy to open and can effectively prevent counterfeit goods.

Common grades of coated bottle cap material aluminum strips include 8011, 3003, 1070, 1060, 5052, etc. The surface is coated, usually with PE coating and epoxy resin coating, etc. The color-coated aluminum strip does not contain bisphenol A, ensuring that the bottle cap is safe and non-toxic, and has no effect on human health. The color and thickness can be customized according to customer needs.

Colored aluminum alloy bottle cap material specifications

| Alloy | 8011, 3003, 1070, 1060, 5052, etc. |

| Temper | H18, H19, H22, H24, H26, H14, H16 |

| Thickness | 0.15-0.5 mm |

| Width | 500~2500 mm |

| Rolling technique | CC/DC |

| Surface treatment | color coating |

| Application | red wine cap, anti-theft bottle cap, perfume bottle cap, skin care bottle cap, cosmetic bottle cap, oil cap, oral liquid aluminum-plastic composite cap, infusion bottle aluminum-plastic cap, etc. |

| Delivery date | 15-21 days |

| Packaging | wooden pallet |

| Sample | free |

| MOQ | 1-3 TONS |

Characteristics of color-coated aluminum closures:

1. Corrosion resistance: The aluminum strip of the coated bottle cap material is treated with a special coating to enhance its corrosion resistance, resist the erosion of various corrosive substances, and extend the service life of the bottle cap.

2. Sealing performance: The coating treatment also improves the sealing performance of the aluminum strip, ensuring the effective sealing of the bottle cap to prevent leakage of internal substances or entry of external impurities.

3. Aesthetics: The coating can give the aluminum strip a variety of colors and textures, enhance the aesthetics of the bottle cap, and meet consumers' high requirements for packaging appearance.

4. Processing performance: The coated bottle cap material aluminum strip has good processing performance, is easy to stamp and form, and is suitable for large-scale automated production.

5. Food safety performance: For bottle caps used for food packaging, the coated bottle cap material aluminum strip also needs to have good food safety performance to ensure that it will not contaminate the internal food.

6. High and low temperature resistance: It can withstand high temperature sterilization treatment, maintain stable performance in low temperature environment, and is not easy to crack or deform.

7. Recyclable performance: Both aluminum materials and coatings can be recycled, which is in line with the concept of green environmental protection.

Color coated aluminum strip process flow:

1. Surface pretreatment

Decontamination: Use a mild detergent to remove oil and dust.

Grinding: Use sandpaper to polish the surface to enhance the adhesion of the coating. The direction of the grain should be consistent and the force should be moderate.

2. Primer coating

Primer selection: Select the appropriate primer according to the characteristics of the aluminum strip, which must have adhesion and anti-penetration ability.

Spraying and drying: Spray the primer evenly and dry it. The coating thickness is controlled at 5-10 microns.

3. Topcoat coating

Topcoat selection: Use a topcoat with good weather resistance and wear resistance.

Spraying and curing: Spray the topcoat evenly and cure it to ensure that the coating performance meets the requirements.

4. Quality inspection and packaging

Quality inspection: Appearance, size, and performance tests ensure that the quality meets the standards.

Packaging: Qualified products are packaged for easy storage and transportation.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan