- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Why is 3105 Aluminum Sheet the Ideal Choice for Closure Caps?

With the continuous advancement of aluminum processing technology, 3105 aluminum sheet has emerged as the preferred material for bottle caps. It not only meets the forming and printing requirements of closure production but also offers lightweight, corrosion-resistant, and eco-friendly benefits. It is widely used in ROPP pilfer-proof caps, screw caps, pharmaceutical closures, yogurt lids, and small bottle seals, making it the ideal choice in the bottle cap industry.

What is 3105 Aluminum Sheet?

3105 aluminum belongs to the 3000-series aluminum alloys, with manganese (Mn) as its main alloying element, typically in the range of 0.3%–0.8%. Compared with 1000-series pure aluminum, it offers higher mechanical strength, better corrosion resistance, and improved formability.

3105 Aluminum Closure Sheet - Product Information

| Alloy | 3105 |

| Temper | H14, H24, H16, H26, H18 |

| Thickness | 0.15-0.5 mm |

| Width | 500-2500 mm |

| Length | 1000-6000 mm |

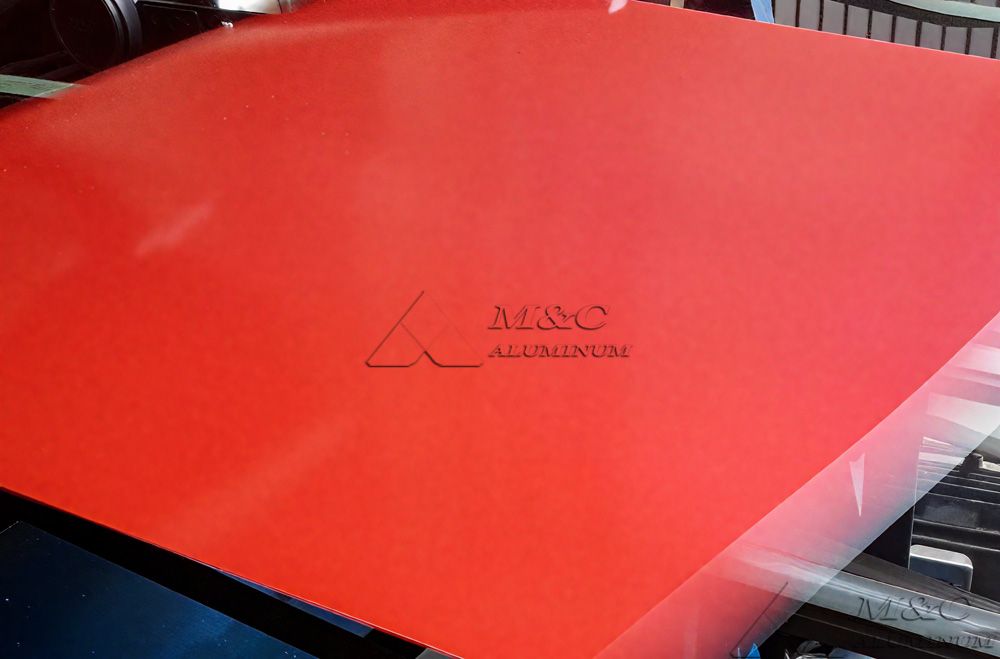

| Surface treatment | Standard mill finish DOS lubricated surface Chromated surface One side colored (gold, white, red, blue, black, etc.) and the other side coated with protective lacquer Both sides with clear/transparent lacquer |

| Applications | ROPP caps, screw caps, wine closures, pilfer-proof caps, beverage caps, olive oil caps, pharmaceutical closures, small bottle seals |

| Packaging | Export-standard wooden cases |

| MOQ | 1-3 tons |

Mechanical Properties of 3105 Aluminum Closure Sheet

| Temper | Thickness (mm) | Tensile Strength (Rm/MPa) | Elongation (%) | Yield Rate (%) |

| H14/H24 | 0.2-0.5 | 150-200 | 2 | 4 |

| H16/H26 | 175-225 | 1 | 4 | |

| H18 | ≥95 | 1 | 4 |

7 Key Reasons Why 3105 Aluminum Sheet is the First Choice for Bottle Caps

1. Outstanding Workability

(1) Excellent ductility & deep drawing performance

3105 aluminum alloy, with added manganese and magnesium, achieves an elongation rate of 20%-25%, far exceeding pure aluminum. This ensures superior performance in stamping, deep drawing, curling, and sealing processes-avoiding cracks and wrinkles while maintaining dimensional accuracy.

(2) Excellent cutting & punching properties

Caps often require vent holes, anti-counterfeit notches, or serrations. 3105 aluminum has moderate hardness-soft enough to prevent excessive tool wear, yet strong enough to resist deformation-supporting high-speed, high-precision mass production.

2. Superior Corrosion Resistance

The manganese content enhances corrosion resistance. A dense oxide film forms naturally on the surface, protecting against neutral liquids and acidic beverages such as juice, soda, or wine.

3. Balanced Strength and Toughness

Caps must maintain internal sealing pressure (especially for carbonated drinks and beer), while remaining easy to open. With a tensile strength of 120–160 MPa, 3105 provides the right balance: strong enough for long-term sealing, yet soft enough for convenient opening.

4. Excellent Surface Treatment Compatibility

3105 aluminum has a surface ideal for printing, lacquering, and coating. Inks and coatings adhere firmly, ensuring brand logos remain sharp and durable-even after forming.

5. Non-Magnetic & Food-Safe

As a non-magnetic, non-toxic alloy, 3105 contains no hazardous heavy metals such as lead or mercury. Its smooth surface meets global food-contact safety standards, making it suitable for water, juice, alcohol, and condiments packaging.

6. Cost Efficiency

Compared with higher-strength alloys (e.g., 5052), 3105 aluminum offers competitive pricing while meeting bottle cap performance requirements-ideal for large-scale production.

7. Recyclability

Aluminum is 100% recyclable without loss of quality. Recycling consumes only 5% of the energy required for primary aluminum production, supporting sustainability goals.

Comparison: Why 3105 Outperforms Other Materials

| Material | Core Advantage | Main Drawback | 3105 Advantage |

| 1060 pure aluminum | Excellent ductility, low cost | Low strength, poor sealing, prone to deformation | Higher strength, better sealing, superior corrosion resistance |

| 3003 aluminum alloy | Good corrosion resistance | Lower ductility, prone to cracking in deep drawing | Better formability, more stable shaping, cost-effective |

| 5052 aluminum alloy | High strength, fatigue resistance | Higher cost, more difficult to process | Balanced strength, lower cost, easier forming |

| Tinplate (steel) | Very high strength | Heavy, rust-prone, requires complex coating | Lightweight, corrosion-resistant, simpler processing, cost advantage |

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan