- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

Bottle Cap Aluminum Closure Sheet Sealing Precautions

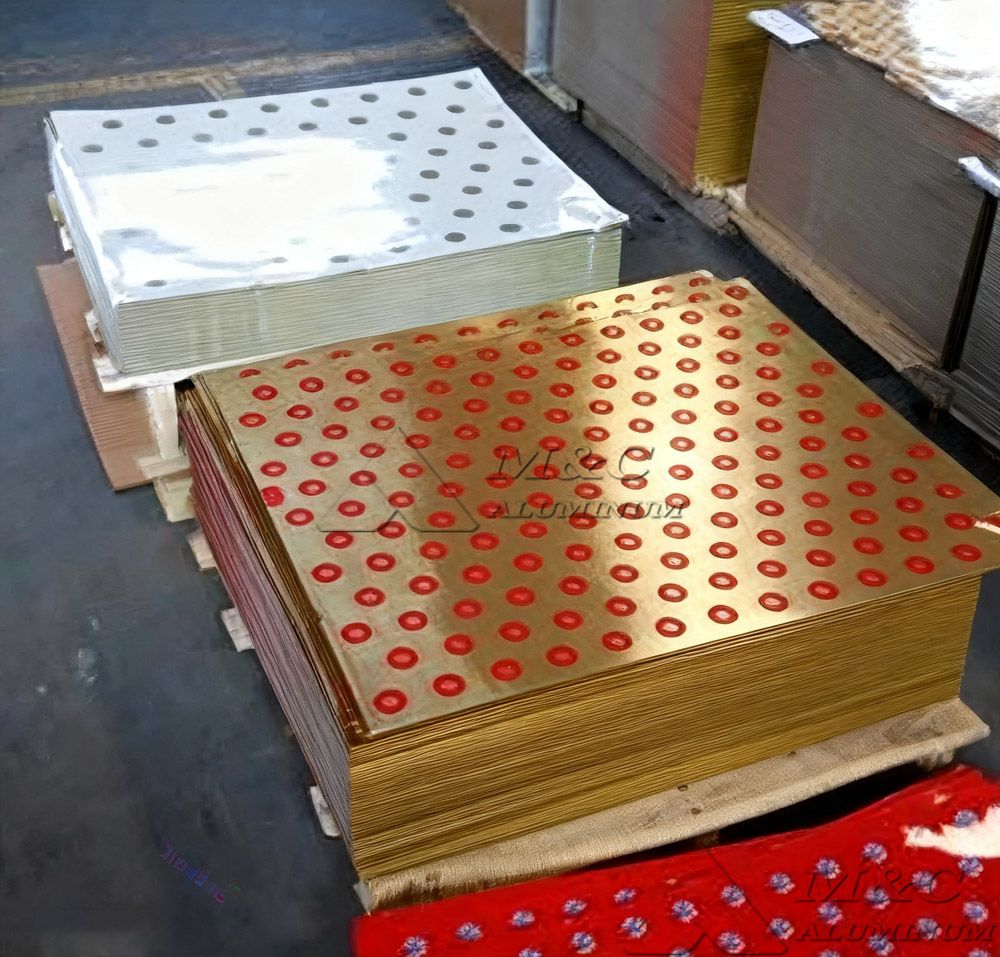

MC Aluminum produces aluminum closure sheets as a key raw material for pilfer-proof caps, pharmaceutical caps, ROPP caps, and easy-open caps. Manufactured through rolling, annealing, and surface treatment processes, these specialized aluminum sheets feature excellent strength, ductility, and surface properties, making them suitable for stamping, printing, and hot stamping. Commonly used alloys include 8011, 3105, and 5052, available in tempers H14, H16, H18, and H19, with thicknesses ranging from 0.15 mm to 0.30 mm.

Common Alloys & Tempers

8011 Aluminum Alloy: Contains small amounts of iron and silicon, which improve its strength while maintaining good ductility. Widely used for pharmaceutical caps and food closures.

3105 Aluminum Alloy: Mainly composed of aluminum, manganese, and magnesium, offering medium strength and excellent corrosion resistance. Suitable for beverage and beer pilfer-proof caps.

5052 Aluminum Alloy: A high-magnesium alloy known for outstanding corrosion resistance and good formability. Stronger than 1xxx and 3xxx alloys, often used for closures requiring higher strength.

Typical Tempers:

H14 / H16: Suitable for screw caps requiring good ductility.

H18 / H19: Higher hardness, ideal for high-speed stamping and strong closures.

Product Information

| Alloy Grades | 8011, 3105, 5052 |

| Tempers | H14, H16, H18, H19 |

| Thickness | 0.15 mm - 0.30 mm |

| Width | 200 mm - 1600 mm |

| Surface Treatment | Coating, printing, colored finish, clear lacquer, anodizing |

| Surface Quality | Flat and smooth, free of scratches, oil stains, or oxidation marks |

| Packaging | Wooden pallets/wooden cases, moisture-proof and oxidation-resistant Samples: Available |

| MOQ | 1-3 tons |

Key Features of Aluminum Closure Sheets

1. Lightweight: Only one-third the weight of steel, lowering transportation costs.

2. Corrosion Resistant: Forms a dense oxide film on the surface, ideal for acidic and alkaline liquids such as beverages and wines.

3. Excellent Workability: Suitable for stamping, deep drawing, printing, and hot stamping, with high yield rates.

4. Eco-Friendly & Recyclable: 100% recyclable, supporting sustainable packaging trends.

5. Customizable: Can be printed with brand logos, designs, or text to enhance product value.

Application Fields

Beverage Closures: Beer caps, carbonated drink caps, juice bottle caps.

Alcoholic Beverage Closures: Pilfer-proof aluminum caps for wine, spirits, and liquor.

Pharmaceutical Closures: Oral liquid caps, infusion bottle caps, tamper-evident medical caps.

Food Packaging: Closures for condiments, dairy products, and other sealed food items.

Personal Care & Cosmetics: Caps for skincare and cosmetic products.

Bottle Cap Sealing Considerations

Material Matching: Before sealing, ensure that the heat-seal layer of the selected aluminum seal plate matches the bottle neck material. For example, PET bottles require aluminum seal plates with specialized heat-seal layers; otherwise, a secure bond will not be achieved.

Temperature, pressure, and time: These three parameters directly determine the quality of the seal. The temperature should be high enough to melt the heat-seal layer, but not too high to burn the bottle. The pressure should be moderate to ensure a tight fit without crushing the bottle neck. The time should be sufficient to ensure a complete heat-seal process. These parameters require experimentation to determine optimal values.

Cleanliness: Before sealing, ensure that the bottle neck and aluminum seal plate are clean and free of oil and water stains. Any impurities will significantly affect the bond and cause air leaks or peeling.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan